What is Oilfield Drilling Fluids- Global Market?

Oilfield drilling fluids, often referred to as drilling muds, are essential components in the oil and gas industry, playing a crucial role in the drilling process. These fluids are used to facilitate the drilling of boreholes into the earth, primarily for the exploration and extraction of oil and natural gas. The global market for oilfield drilling fluids is vast and complex, driven by the continuous demand for energy and the exploration of new oil and gas reserves. These fluids serve multiple purposes, such as cooling and lubricating the drill bit, carrying drill cuttings to the surface, maintaining hydrostatic pressure to prevent formation fluids from entering the wellbore, and stabilizing the wellbore walls. The market is influenced by various factors, including technological advancements, environmental regulations, and the fluctuating prices of oil and gas. As the industry evolves, there is a growing emphasis on developing more efficient and environmentally friendly drilling fluids to meet the stringent environmental standards and reduce the ecological impact of drilling activities. The global market for oilfield drilling fluids is poised for growth, driven by the increasing exploration activities in both onshore and offshore regions and the need for advanced drilling technologies.

Water-Based Fluids, Oil-Based Fluids, Other in the Oilfield Drilling Fluids- Global Market:

Water-based fluids, oil-based fluids, and other types of drilling fluids each play distinct roles in the oilfield drilling fluids market, catering to different drilling conditions and environmental considerations. Water-based fluids are the most commonly used type of drilling fluid, primarily due to their cost-effectiveness and environmental friendliness. These fluids are composed mainly of water, with various additives to enhance their properties. They are particularly suitable for drilling in formations where the risk of formation damage is minimal. Water-based fluids are preferred in environmentally sensitive areas due to their lower environmental impact compared to oil-based fluids. However, they may not perform as well in challenging drilling conditions, such as high-temperature and high-pressure environments, where oil-based fluids might be more effective. Oil-based fluids, on the other hand, are composed of a base oil, such as diesel or mineral oil, and are known for their superior performance in challenging drilling conditions. They offer excellent lubrication, thermal stability, and shale inhibition, making them ideal for drilling in deep and complex wells. Oil-based fluids are particularly effective in preventing wellbore instability and minimizing the risk of stuck pipe incidents. However, their use is often restricted due to environmental concerns, as they can be more challenging to dispose of and may pose a higher risk of environmental contamination. As a result, the industry is continuously seeking ways to improve the environmental profile of oil-based fluids, such as developing synthetic-based fluids that offer similar performance benefits with reduced environmental impact. In addition to water-based and oil-based fluids, there are other types of drilling fluids that cater to specific drilling needs. Synthetic-based fluids, for example, are designed to combine the advantages of both water-based and oil-based fluids. They offer excellent performance in challenging drilling conditions while being more environmentally friendly than traditional oil-based fluids. Synthetic-based fluids are often used in offshore drilling operations, where environmental regulations are more stringent. Another category of drilling fluids includes pneumatic drilling fluids, which use air, mist, or foam as the drilling medium. These fluids are typically used in areas where the formation is highly fractured or where there is a risk of lost circulation. Each type of drilling fluid has its own set of advantages and limitations, and the choice of fluid depends on various factors, including the geological conditions, environmental regulations, and cost considerations. As the oil and gas industry continues to evolve, there is a growing emphasis on developing innovative drilling fluid technologies that enhance performance, reduce costs, and minimize environmental impact.

Onshore Drilling, Offshore Drilling in the Oilfield Drilling Fluids- Global Market:

The usage of oilfield drilling fluids in onshore and offshore drilling operations is critical to the success and efficiency of the drilling process. In onshore drilling, where wells are drilled on land, drilling fluids play a vital role in maintaining wellbore stability and preventing formation damage. The choice of drilling fluid in onshore operations depends on various factors, including the geological conditions, the depth of the well, and environmental considerations. Water-based fluids are commonly used in onshore drilling due to their cost-effectiveness and lower environmental impact. However, in challenging drilling conditions, such as high-temperature and high-pressure formations, oil-based or synthetic-based fluids may be preferred for their superior performance and ability to prevent wellbore instability. Offshore drilling, which involves drilling wells in bodies of water, presents unique challenges that require specialized drilling fluids. The harsh environmental conditions, such as high pressures and temperatures, as well as the need to comply with stringent environmental regulations, make the choice of drilling fluid critical in offshore operations. Synthetic-based fluids are often used in offshore drilling due to their excellent performance in challenging conditions and their reduced environmental impact compared to traditional oil-based fluids. These fluids provide the necessary lubrication and thermal stability required for deepwater drilling while minimizing the risk of environmental contamination. Additionally, the use of synthetic-based fluids in offshore drilling helps to reduce the risk of wellbore instability and stuck pipe incidents, which can be costly and time-consuming to resolve. In both onshore and offshore drilling, the selection of drilling fluids is a complex process that involves careful consideration of various factors, including the geological conditions, environmental regulations, and cost considerations. The choice of fluid can significantly impact the efficiency and success of the drilling operation, as well as the overall cost of the project. As the oil and gas industry continues to evolve, there is a growing emphasis on developing innovative drilling fluid technologies that enhance performance, reduce costs, and minimize environmental impact. This includes the development of new additives and formulations that improve the properties of drilling fluids, as well as the use of advanced monitoring and control systems to optimize fluid performance during drilling operations. The continued advancement of drilling fluid technologies is essential to meeting the challenges of modern drilling operations and ensuring the sustainable development of oil and gas resources.

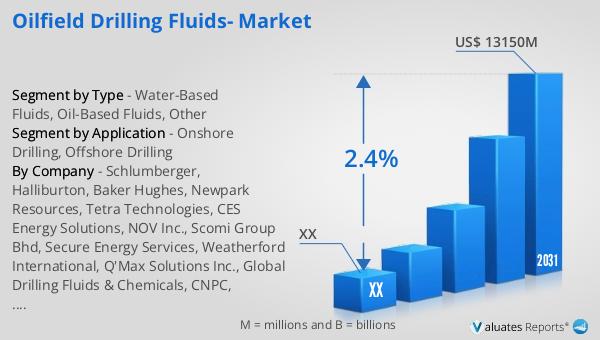

Oilfield Drilling Fluids- Global Market Outlook:

The global market for oilfield drilling fluids is projected to experience steady growth in the coming years. In 2024, the market was valued at approximately US$ 11,140 million. By 2031, it is anticipated to reach a revised size of around US$ 13,150 million, reflecting a compound annual growth rate (CAGR) of 2.4% during the forecast period from 2025 to 2031. This growth is driven by several factors, including the increasing demand for energy, the exploration of new oil and gas reserves, and the need for advanced drilling technologies. The market is also influenced by environmental regulations, which are driving the development of more environmentally friendly drilling fluids. As the industry continues to evolve, there is a growing emphasis on developing innovative drilling fluid technologies that enhance performance, reduce costs, and minimize environmental impact. This includes the development of new additives and formulations that improve the properties of drilling fluids, as well as the use of advanced monitoring and control systems to optimize fluid performance during drilling operations. The continued advancement of drilling fluid technologies is essential to meeting the challenges of modern drilling operations and ensuring the sustainable development of oil and gas resources.

| Report Metric | Details |

| Report Name | Oilfield Drilling Fluids- Market |

| Forecasted market size in 2031 | US$ 13150 million |

| CAGR | 2.4% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Schlumberger, Halliburton, Baker Hughes, Newpark Resources, Tetra Technologies, CES Energy Solutions, NOV Inc., Scomi Group Bhd, Secure Energy Services, Weatherford International, Q'Max Solutions Inc., Global Drilling Fluids & Chemicals, CNPC, Sinopec, CNOOC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |