What is Vibration Sensors- Global Market?

Vibration sensors are essential components in various industries, playing a crucial role in monitoring and maintaining the health of machinery and equipment. These sensors detect and measure vibrations, providing valuable data that can be used to predict equipment failures, optimize maintenance schedules, and enhance operational efficiency. The global market for vibration sensors is driven by the increasing demand for predictive maintenance and the need to reduce downtime in industrial operations. As industries continue to adopt automation and smart technologies, the integration of vibration sensors into equipment and systems becomes increasingly important. These sensors are used in a wide range of applications, from monitoring the condition of rotating machinery in manufacturing plants to ensuring the safety and reliability of vehicles in the automotive industry. The market is characterized by a diverse range of sensor types, including accelerometers, velocity sensors, and displacement sensors, each offering unique advantages for specific applications. As technology advances, the development of more sophisticated and accurate vibration sensors is expected to further drive market growth, providing industries with the tools they need to maintain optimal performance and reduce operational costs.

Short-range Wireless Technology, LPWAN Technology in the Vibration Sensors- Global Market:

Short-range wireless technology and Low Power Wide Area Network (LPWAN) technology are two significant advancements in the vibration sensors market, offering unique benefits for various applications. Short-range wireless technology, such as Bluetooth and Zigbee, enables the seamless transmission of data from vibration sensors to monitoring systems without the need for extensive wiring. This technology is particularly beneficial in environments where wiring is impractical or costly, such as in large manufacturing plants or remote locations. The ease of installation and flexibility offered by short-range wireless technology make it an attractive option for industries looking to implement condition monitoring systems quickly and efficiently. Additionally, the ability to connect multiple sensors to a single network allows for comprehensive monitoring of equipment and machinery, providing real-time data that can be used to optimize maintenance schedules and improve operational efficiency. On the other hand, LPWAN technology offers a different set of advantages, particularly for applications that require long-range communication and low power consumption. LPWAN technologies, such as LoRaWAN and NB-IoT, are designed to transmit small amounts of data over long distances, making them ideal for monitoring equipment in remote or hard-to-reach locations. The low power consumption of LPWAN devices ensures that vibration sensors can operate for extended periods without the need for frequent battery replacements, reducing maintenance costs and improving reliability. This technology is particularly useful in industries such as oil and gas, where equipment is often located in remote areas and requires constant monitoring to ensure safety and efficiency. By leveraging the strengths of both short-range wireless and LPWAN technologies, industries can implement comprehensive vibration monitoring systems that provide valuable insights into equipment performance and health. These technologies enable the collection and analysis of data from multiple sensors, allowing for the early detection of potential issues and the implementation of predictive maintenance strategies. As a result, industries can reduce downtime, extend the lifespan of equipment, and improve overall operational efficiency. The integration of these technologies into vibration sensors is expected to drive significant growth in the global market, as more industries recognize the benefits of advanced monitoring solutions. Furthermore, the development of new and innovative wireless technologies is likely to enhance the capabilities of vibration sensors, providing even greater opportunities for market expansion. As industries continue to embrace digital transformation and the Internet of Things (IoT), the demand for advanced vibration sensors and wireless technologies is expected to increase, driving further innovation and growth in the market. The combination of short-range wireless and LPWAN technologies offers a powerful solution for industries looking to optimize their operations and improve the reliability of their equipment, making them an essential component of modern industrial systems.

Manufacturing, Automotive, Energy and Power, Oil and Gas, Metals and Mining, Chemicals, Others in the Vibration Sensors- Global Market:

Vibration sensors play a vital role in various industries, providing critical data that helps optimize operations and ensure the reliability of equipment. In the manufacturing sector, vibration sensors are used to monitor the condition of machinery and equipment, enabling predictive maintenance and reducing downtime. By detecting changes in vibration patterns, these sensors can identify potential issues before they lead to equipment failure, allowing for timely maintenance and repairs. This not only extends the lifespan of machinery but also improves overall operational efficiency. In the automotive industry, vibration sensors are used to enhance vehicle safety and performance. They monitor the condition of critical components, such as engines and suspension systems, providing real-time data that can be used to optimize vehicle performance and ensure passenger safety. In the energy and power sector, vibration sensors are used to monitor the condition of turbines, generators, and other critical equipment. By providing early warning of potential issues, these sensors help prevent costly downtime and ensure the reliable operation of power plants. In the oil and gas industry, vibration sensors are used to monitor the condition of drilling equipment and pipelines, ensuring the safety and efficiency of operations. These sensors provide valuable data that can be used to optimize maintenance schedules and reduce the risk of equipment failure. In the metals and mining industry, vibration sensors are used to monitor the condition of crushers, mills, and other critical equipment. By detecting changes in vibration patterns, these sensors can identify potential issues before they lead to equipment failure, allowing for timely maintenance and repairs. This not only extends the lifespan of machinery but also improves overall operational efficiency. In the chemicals industry, vibration sensors are used to monitor the condition of pumps, compressors, and other critical equipment. By providing early warning of potential issues, these sensors help prevent costly downtime and ensure the reliable operation of chemical plants. In addition to these industries, vibration sensors are also used in a variety of other applications, such as monitoring the condition of bridges and other infrastructure, ensuring the safety and reliability of public transportation systems, and optimizing the performance of industrial robots. As technology advances, the development of more sophisticated and accurate vibration sensors is expected to further drive market growth, providing industries with the tools they need to maintain optimal performance and reduce operational costs.

Vibration Sensors- Global Market Outlook:

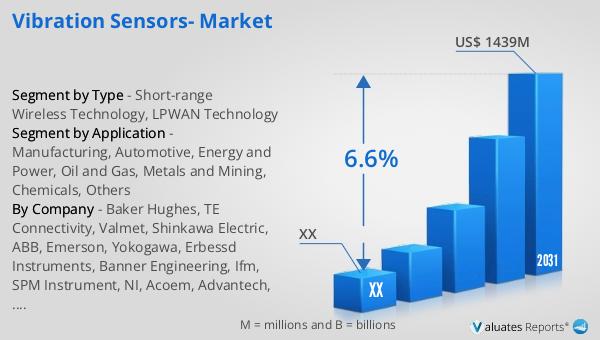

The global market for vibration sensors is projected to grow significantly in the coming years. In 2024, the market was valued at approximately $926 million, and it is anticipated to reach an adjusted size of $1,439 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.6% during the forecast period from 2025 to 2031. The market is dominated by the top five players, who collectively hold about 51% of the market share. The Asia-Pacific region is the largest market for vibration sensors, accounting for approximately 41% of the global market. This is followed by North America and Europe, which hold shares of 26% and 23%, respectively. In terms of product type, short-range wireless technology is the largest segment, occupying a substantial 73% share of the market. This technology's dominance is attributed to its ease of installation and flexibility, making it an attractive option for various industries. In terms of application, the manufacturing sector is the largest user of vibration sensors, accounting for 24% of the market share. The widespread adoption of vibration sensors in manufacturing is driven by the need for predictive maintenance and the desire to reduce downtime and improve operational efficiency. As industries continue to embrace digital transformation and the Internet of Things (IoT), the demand for advanced vibration sensors is expected to increase, driving further innovation and growth in the market.

| Report Metric | Details |

| Report Name | Vibration Sensors- Market |

| Forecasted market size in 2031 | US$ 1439 million |

| CAGR | 6.6% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Baker Hughes, TE Connectivity, Valmet, Shinkawa Electric, ABB, Emerson, Yokogawa, Erbessd Instruments, Banner Engineering, Ifm, SPM Instrument, NI, Acoem, Advantech, Fluke, Sumyoung Tech |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |