What is Medical Elastomers- Global Market?

Medical elastomers are specialized materials used extensively in the healthcare industry due to their unique properties, such as flexibility, durability, and biocompatibility. These materials are primarily used in the production of medical devices and consumables, where they play a crucial role in ensuring safety and performance. The global market for medical elastomers is driven by the increasing demand for advanced medical devices and the growing healthcare sector worldwide. As the population ages and the prevalence of chronic diseases rises, the need for reliable and efficient medical products becomes more critical. Medical elastomers offer the versatility required to meet these demands, providing solutions that can be tailored to specific applications. They are used in a wide range of products, from surgical instruments to drug delivery systems, highlighting their importance in modern medicine. The market is characterized by continuous innovation, with manufacturers striving to develop new formulations that enhance the performance and safety of medical products. This dynamic environment fosters growth and presents opportunities for companies to expand their offerings and capture a larger share of the market. As a result, the global market for medical elastomers is poised for significant growth in the coming years, driven by technological advancements and the increasing need for high-quality medical products.

Thermosetting Elastomer, Thermoplastic Elastomer in the Medical Elastomers- Global Market:

Thermosetting elastomers and thermoplastic elastomers are two primary types of materials used in the medical elastomers market, each offering distinct properties and applications. Thermosetting elastomers are materials that undergo a curing process, resulting in a permanent set shape that cannot be re-melted or re-shaped. This characteristic makes them ideal for applications requiring high durability and resistance to deformation under stress. In the medical field, thermosetting elastomers are often used in applications where long-term stability and resistance to harsh conditions are essential. For example, they are commonly used in the production of medical implants and prosthetics, where their ability to maintain structural integrity over time is crucial. These materials are also used in the manufacturing of seals and gaskets for medical devices, where their resistance to chemicals and temperature fluctuations ensures reliable performance. On the other hand, thermoplastic elastomers are materials that can be repeatedly melted and reshaped, offering greater flexibility and ease of processing. This property makes them highly versatile and suitable for a wide range of medical applications. Thermoplastic elastomers are often used in the production of medical tubing, catheters, and other disposable medical products, where their ability to be easily molded into complex shapes is advantageous. Additionally, these materials are used in the manufacturing of medical packaging, providing a flexible and durable solution for protecting sensitive medical products. The ability to recycle and reprocess thermoplastic elastomers also contributes to their appeal, as it aligns with the growing emphasis on sustainability in the healthcare industry. The global market for medical elastomers is witnessing a shift towards the increased use of thermoplastic elastomers, driven by their versatility and cost-effectiveness. As healthcare providers seek to reduce costs and improve efficiency, the demand for materials that offer both performance and economic benefits is rising. Thermoplastic elastomers meet these criteria, providing a balance between functionality and affordability that is attractive to manufacturers and end-users alike. Furthermore, advancements in material science are leading to the development of new thermoplastic elastomer formulations with enhanced properties, such as improved biocompatibility and resistance to sterilization processes. These innovations are expanding the range of applications for thermoplastic elastomers in the medical field, further driving their adoption. In summary, both thermosetting and thermoplastic elastomers play vital roles in the medical elastomers market, each offering unique advantages that cater to different needs within the healthcare industry. While thermosetting elastomers provide the durability and stability required for long-term applications, thermoplastic elastomers offer the flexibility and ease of processing needed for disposable and complex medical products. The ongoing advancements in material technology and the growing demand for high-performance medical products are expected to continue driving the growth of the medical elastomers market, with thermoplastic elastomers leading the way due to their versatility and cost-effectiveness.

Medical Devices, Medical Consumables, Others in the Medical Elastomers- Global Market:

Medical elastomers are integral to the production of various medical devices, consumables, and other healthcare-related products, owing to their unique properties such as flexibility, durability, and biocompatibility. In the realm of medical devices, elastomers are used extensively in the manufacturing of components that require precision and reliability. For instance, they are employed in the production of seals, gaskets, and diaphragms for medical equipment, ensuring that these devices function effectively without leaks or failures. The flexibility of elastomers allows for the creation of intricate designs and shapes, which is essential for the development of advanced medical devices that cater to specific patient needs. Additionally, elastomers are used in the production of medical implants and prosthetics, where their ability to mimic the properties of natural tissues enhances patient comfort and outcomes. In the area of medical consumables, elastomers are used in the production of a wide range of products, including syringes, vials, and stoppers. These materials provide the necessary barrier properties to protect the contents from contamination and ensure the safety and efficacy of the medical products. The use of elastomers in medical consumables is driven by the need for materials that can withstand sterilization processes and maintain their integrity under various conditions. Furthermore, elastomers are used in the production of medical tubing and catheters, where their flexibility and biocompatibility are crucial for patient safety and comfort. The ability to produce elastomers in various colors and textures also allows for customization, which is important for branding and product differentiation in the competitive medical consumables market. Beyond medical devices and consumables, elastomers find applications in other areas of the healthcare industry, such as drug delivery systems and wound care products. In drug delivery, elastomers are used to create flexible and durable components that facilitate the controlled release of medications, improving patient compliance and treatment outcomes. The biocompatibility of elastomers ensures that these systems are safe for use in the human body, minimizing the risk of adverse reactions. In wound care, elastomers are used in the production of dressings and bandages that provide a protective barrier while allowing the skin to breathe and heal. The flexibility and conformability of elastomers make them ideal for use in wound care products, as they can adapt to the contours of the body and provide a comfortable fit. Overall, the use of medical elastomers in various healthcare applications underscores their importance in the industry. Their unique properties enable the development of innovative products that enhance patient care and improve clinical outcomes. As the demand for advanced medical products continues to grow, the role of elastomers in the healthcare industry is expected to expand, driven by ongoing advancements in material science and technology.

Medical Elastomers- Global Market Outlook:

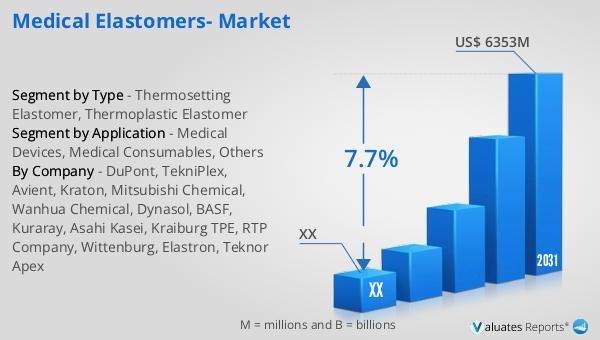

The global market for medical elastomers is projected to experience significant growth, with its value estimated at approximately US$ 3,812 million in 2024. By 2031, this market is anticipated to reach a revised size of US$ 6,353 million, reflecting a compound annual growth rate (CAGR) of 7.7% during the forecast period from 2025 to 2031. The market is characterized by a competitive landscape, with the top five players collectively holding around 28% of the market share. Among the regions, China emerges as the largest market, accounting for about 32% of the global share, followed by North America and Europe, which hold shares of 24% and 22%, respectively. In terms of product types, thermoplastic elastomers dominate the market, representing approximately 64% of the total share. This dominance is attributed to their versatility and cost-effectiveness, which make them a preferred choice for various medical applications. When it comes to applications, medical consumables constitute the largest segment, capturing about 56% of the market share. This significant share underscores the critical role of elastomers in the production of essential medical products that are used daily in healthcare settings. The market dynamics highlight the growing demand for high-performance materials that can meet the stringent requirements of the medical industry, driving innovation and expansion in the medical elastomers market.

| Report Metric | Details |

| Report Name | Medical Elastomers- Market |

| Forecasted market size in 2031 | US$ 6353 million |

| CAGR | 7.7% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | DuPont, TekniPlex, Avient, Kraton, Mitsubishi Chemical, Wanhua Chemical, Dynasol, BASF, Kuraray, Asahi Kasei, Kraiburg TPE, RTP Company, Wittenburg, Elastron, Teknor Apex |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |