What is MBS Impact Modifiers- Global Market?

MBS Impact Modifiers, or Methacrylate Butadiene Styrene impact modifiers, play a crucial role in enhancing the durability and performance of various plastic products. These modifiers are primarily used to improve the impact resistance of PVC and other polymers, making them more robust and long-lasting. The global market for MBS Impact Modifiers is driven by the increasing demand for high-performance materials in various industries, including construction, automotive, and packaging. As industries continue to seek materials that offer both strength and flexibility, MBS Impact Modifiers have become essential. They help in maintaining the clarity and transparency of products while providing the necessary toughness. This balance of properties makes them particularly valuable in applications where both aesthetics and durability are important. The market is characterized by a steady growth trajectory, fueled by technological advancements and the rising need for sustainable and efficient materials. As manufacturers strive to meet the evolving demands of consumers, the role of MBS Impact Modifiers in the global market is expected to expand, offering new opportunities for innovation and development.

in the MBS Impact Modifiers- Global Market:

The global market for MBS Impact Modifiers is diverse, catering to a wide range of applications and customer needs. Different types of MBS Impact Modifiers are used based on the specific requirements of the end-users. Transparent MBS for PVC is one of the most popular types, accounting for a significant share of the market. This type is particularly favored in applications where clarity and transparency are crucial, such as in packaging and film. Customers in the packaging industry prefer this type because it not only enhances the impact resistance of the material but also maintains its visual appeal. Another type of MBS Impact Modifier is the opaque variant, which is used in applications where transparency is not a priority. This type is often used in the construction industry, particularly in the production of pipes and fittings, where durability and strength are more important than appearance. The automotive industry also utilizes MBS Impact Modifiers, particularly in the production of interior and exterior components that require high impact resistance and durability. Customers in this sector value the ability of MBS Impact Modifiers to enhance the performance of materials without compromising on weight, which is crucial for fuel efficiency. Additionally, there are specialized MBS Impact Modifiers designed for specific applications, such as those used in the production of medical devices and electronics. These modifiers are formulated to meet the stringent requirements of these industries, including biocompatibility and electrical insulation. The versatility of MBS Impact Modifiers makes them suitable for a wide range of applications, and their ability to enhance the performance of materials while maintaining their aesthetic appeal is a key factor driving their adoption across various industries. As the demand for high-performance materials continues to grow, the market for MBS Impact Modifiers is expected to expand, offering new opportunities for innovation and development.

Packaging and Film, Pipes and Fittings, Others in the MBS Impact Modifiers- Global Market:

MBS Impact Modifiers are widely used in various applications, including packaging and film, pipes and fittings, and other sectors. In the packaging and film industry, MBS Impact Modifiers are valued for their ability to enhance the impact resistance of materials while maintaining their clarity and transparency. This is particularly important in the production of packaging materials, where both durability and visual appeal are crucial. MBS Impact Modifiers help in creating packaging solutions that are not only strong and durable but also visually appealing, making them ideal for consumer products. In the production of films, these modifiers enhance the toughness of the material, allowing it to withstand handling and transportation without damage. In the pipes and fittings industry, MBS Impact Modifiers are used to enhance the durability and strength of PVC pipes and fittings. These modifiers improve the impact resistance of the material, making it more robust and long-lasting. This is particularly important in applications where the pipes and fittings are exposed to harsh environmental conditions or heavy loads. The use of MBS Impact Modifiers in this sector helps in extending the lifespan of the products, reducing the need for frequent replacements and maintenance. In addition to packaging and film, and pipes and fittings, MBS Impact Modifiers are also used in other applications, such as automotive components, medical devices, and electronics. In the automotive industry, these modifiers are used to enhance the performance of interior and exterior components, providing the necessary impact resistance and durability without adding extra weight. In the medical and electronics industries, MBS Impact Modifiers are used to meet the specific requirements of these sectors, such as biocompatibility and electrical insulation. The versatility of MBS Impact Modifiers makes them suitable for a wide range of applications, and their ability to enhance the performance of materials while maintaining their aesthetic appeal is a key factor driving their adoption across various industries.

MBS Impact Modifiers- Global Market Outlook:

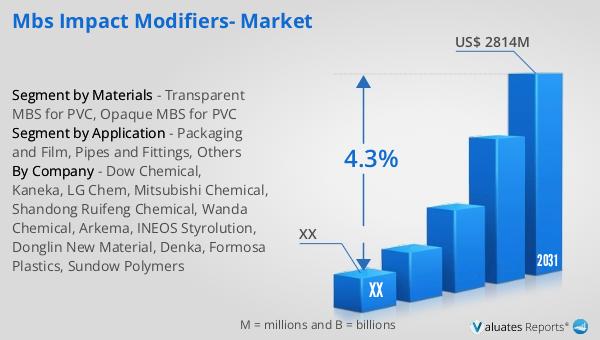

The global market for MBS Impact Modifiers was valued at approximately US$ 2,099 million in 2024, with projections indicating a growth to around US$ 2,814 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.3% during the forecast period from 2025 to 2031. The market is dominated by the top five players, who collectively hold a market share exceeding 58%. The Asia-Pacific region emerges as the largest market for MBS Impact Modifiers, accounting for about 57% of the global share. Within the product types, Transparent MBS for PVC stands out as the largest segment, occupying a 60% share of the market. This segment's prominence is attributed to its widespread use in applications where clarity and transparency are essential, such as in packaging and film. In terms of application, the packaging and film sector holds a significant share of approximately 42%. This sector's dominance is driven by the increasing demand for durable and visually appealing packaging solutions that can withstand handling and transportation. The market outlook for MBS Impact Modifiers reflects a steady growth trajectory, supported by the rising demand for high-performance materials across various industries. As manufacturers continue to innovate and develop new applications for these modifiers, the market is poised for further expansion, offering new opportunities for growth and development.

| Report Metric | Details |

| Report Name | MBS Impact Modifiers- Market |

| Forecasted market size in 2031 | US$ 2814 million |

| CAGR | 4.3% |

| Forecasted years | 2025 - 2031 |

| Segment by Materials |

|

| Segment by Application |

|

| By Region |

|

| By Company | Dow Chemical, Kaneka, LG Chem, Mitsubishi Chemical, Shandong Ruifeng Chemical, Wanda Chemical, Arkema, INEOS Styrolution, Donglin New Material, Denka, Formosa Plastics, Sundow Polymers |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |