What is Dental Milling Machine- Global Market?

Dental milling machines are essential tools in the dental industry, designed to create precise dental restorations such as crowns, bridges, and dentures. These machines use computer-aided design and manufacturing (CAD/CAM) technology to carve out dental prosthetics from blocks of materials like ceramics, zirconia, and composites. The global market for dental milling machines is expanding due to the increasing demand for advanced dental care solutions and the growing adoption of digital dentistry. These machines offer high precision, efficiency, and the ability to produce complex shapes, which are crucial for creating custom-fit dental appliances. The market is driven by technological advancements, the rising prevalence of dental disorders, and the growing awareness of oral health. Additionally, the shift towards minimally invasive procedures and the increasing number of dental clinics and laboratories worldwide contribute to the market's growth. As dental professionals seek to enhance patient outcomes and streamline operations, the demand for dental milling machines continues to rise, making it a vital component of modern dental practices.

4 Axis, 5 Axis, Others in the Dental Milling Machine- Global Market:

In the realm of dental milling machines, the differentiation between 4-axis, 5-axis, and other configurations plays a significant role in determining the capabilities and applications of these machines. A 4-axis dental milling machine operates with four degrees of freedom, allowing it to move in the X, Y, and Z axes, along with an additional rotational axis. This configuration is suitable for producing a wide range of dental restorations, including crowns and bridges, with a high degree of accuracy. The 4-axis machines are often favored for their balance between cost and functionality, making them a popular choice for dental labs and clinics that require reliable performance without the need for the most advanced features. On the other hand, 5-axis dental milling machines offer an additional rotational axis, providing five degrees of freedom. This extra axis allows for more complex and intricate milling tasks, enabling the creation of highly detailed and precise dental prosthetics. The 5-axis machines are particularly beneficial for producing complex geometries and undercuts, which are essential for certain types of dental restorations. These machines are often used in high-end dental labs and clinics that demand the highest level of precision and versatility. The ability to mill from multiple angles without repositioning the material enhances efficiency and reduces the risk of errors, making 5-axis machines a preferred choice for advanced dental applications. Beyond the 4-axis and 5-axis configurations, there are other types of dental milling machines that cater to specific needs and preferences. Some machines are designed for specialized tasks, such as milling implant abutments or creating orthodontic appliances. These machines may incorporate unique features or technologies to address the specific requirements of these applications. Additionally, some dental milling machines are equipped with automation capabilities, allowing for unattended operation and increased productivity. The choice between 4-axis, 5-axis, and other configurations depends on various factors, including the complexity of the dental restorations being produced, the volume of production, and the budget constraints of the dental practice or laboratory. While 4-axis machines offer a cost-effective solution for many standard dental applications, 5-axis machines provide the flexibility and precision needed for more intricate and demanding tasks. As the dental industry continues to evolve, the demand for advanced milling solutions is expected to grow, driving innovation and development in this field. Dental professionals must carefully consider their specific needs and objectives when selecting a milling machine, ensuring that they choose a solution that aligns with their practice's goals and enhances their ability to deliver high-quality dental care.

Dental Lab, Dental Clinic, Others in the Dental Milling Machine- Global Market:

Dental milling machines are utilized in various settings, including dental labs, dental clinics, and other specialized environments, each with its unique requirements and applications. In dental labs, these machines play a crucial role in the production of dental restorations. Dental labs often handle a high volume of cases, requiring efficient and precise milling solutions to meet the demands of dental professionals. The use of dental milling machines in labs allows for the rapid production of custom-fit crowns, bridges, and other prosthetics, ensuring that dental practitioners can provide timely and accurate treatments to their patients. The ability to produce high-quality restorations with minimal manual intervention enhances the lab's productivity and reduces the turnaround time for dental cases. In dental clinics, milling machines are increasingly being adopted as part of the shift towards digital dentistry. Clinics that incorporate milling machines into their workflow can offer same-day restorations, significantly improving the patient experience. The ability to design and mill dental prosthetics on-site allows for immediate placement, reducing the need for multiple appointments and enhancing patient satisfaction. This capability is particularly beneficial for clinics that prioritize patient convenience and seek to differentiate themselves in a competitive market. Additionally, the use of milling machines in clinics can streamline operations, reduce reliance on external labs, and improve the overall efficiency of the practice. Beyond dental labs and clinics, dental milling machines find applications in other areas, such as educational institutions and research facilities. In educational settings, these machines serve as valuable tools for training future dental professionals, providing hands-on experience with the latest digital technologies. Students can learn about the design and fabrication of dental restorations, gaining practical skills that are essential for their future careers. In research facilities, dental milling machines are used to explore new materials, techniques, and applications, contributing to the advancement of dental science and technology. The versatility and precision of these machines make them indispensable in various contexts, supporting the ongoing development and improvement of dental care. As the dental industry continues to embrace digital solutions, the use of milling machines is expected to expand, driving innovation and enhancing the quality of dental treatments worldwide.

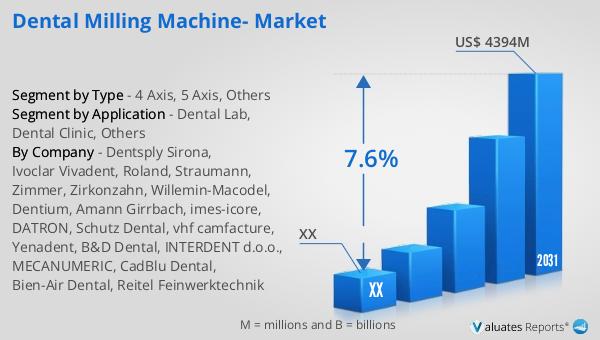

Dental Milling Machine- Global Market Outlook:

The global market for dental milling machines is poised for significant growth in the coming years. In 2024, the market was valued at approximately US$ 2,650 million, and it is projected to reach a revised size of US$ 4,394 million by 2031, reflecting a compound annual growth rate (CAGR) of 7.6% during the forecast period from 2025 to 2031. The market is characterized by a high level of concentration, with the top five players accounting for about 65% of the market share. Europe emerges as the largest market for dental milling machines, holding a substantial share of approximately 48%. This is followed by North America and the Asia Pacific region, which account for 31% and 15% of the market share, respectively. In terms of product type, the 5-axis segment dominates the market, occupying a significant share of 72%. This reflects the growing demand for advanced milling solutions that offer enhanced precision and versatility. When it comes to applications, dental clinics represent the largest field, with a commanding share of about 78%. This underscores the increasing adoption of milling machines in clinical settings, driven by the need for efficient and high-quality dental restorations. As the market continues to evolve, dental professionals and manufacturers alike are focused on leveraging technological advancements to meet the growing demand for digital dentistry solutions.

| Report Metric | Details |

| Report Name | Dental Milling Machine- Market |

| Forecasted market size in 2031 | US$ 4394 million |

| CAGR | 7.6% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Dentsply Sirona, Ivoclar Vivadent, Roland, Straumann, Zimmer, Zirkonzahn, Willemin-Macodel, Dentium, Amann Girrbach, imes-icore, DATRON, Schutz Dental, vhf camfacture, Yenadent, B&D Dental, INTERDENT d.o.o., MECANUMERIC, CadBlu Dental, Bien-Air Dental, Reitel Feinwerktechnik |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |