What is High-Temperature Coating- Global Market?

High-temperature coatings are specialized materials designed to withstand extreme temperatures while providing protection and durability to various surfaces. These coatings are essential in industries where equipment and structures are exposed to high heat, such as aerospace, automotive, and power plants. They are formulated to resist thermal degradation, corrosion, and oxidation, ensuring the longevity and efficiency of the components they cover. The global market for high-temperature coatings is driven by the increasing demand for heat-resistant materials in industrial applications. As industries continue to evolve and expand, the need for reliable and effective high-temperature coatings grows, making it a vital component in maintaining operational efficiency and safety. These coatings not only enhance the performance of machinery and equipment but also contribute to energy savings by improving thermal insulation. With advancements in technology and materials science, high-temperature coatings are becoming more sophisticated, offering enhanced protection and longer service life. The market is characterized by a diverse range of products, each tailored to specific applications and environmental conditions, ensuring that industries can find the right solution for their unique needs. As a result, the high-temperature coating market is poised for continued growth and innovation.

Liquid Resin and Polymer Coating, Heat-Resistant Powder Coating, Others in the High-Temperature Coating- Global Market:

High-temperature coatings are categorized into several types, each with unique properties and applications. Liquid resin and polymer coatings are among the most common, known for their versatility and ease of application. These coatings are typically applied as a liquid and then cured to form a solid, protective layer. They are favored for their ability to adhere to various substrates, including metals and ceramics, providing a robust barrier against heat and corrosion. Liquid resin and polymer coatings are often used in industries where flexibility and adaptability are crucial, such as automotive and aerospace. Heat-resistant powder coatings, on the other hand, are applied as a dry powder and then cured under heat to form a hard, durable finish. These coatings are renowned for their excellent thermal stability and resistance to chipping, scratching, and fading. They are commonly used in applications where a tough, long-lasting finish is required, such as in the manufacturing of industrial machinery and equipment. Other types of high-temperature coatings include ceramic coatings, which offer exceptional thermal insulation and resistance to extreme temperatures. These coatings are often used in high-performance applications, such as in the aerospace and defense industries, where components are exposed to intense heat and pressure. Additionally, there are specialized coatings designed for specific environments, such as those with high levels of humidity or chemical exposure. These coatings are formulated to provide additional protection against environmental factors, ensuring the longevity and reliability of the coated surfaces. The global market for high-temperature coatings is diverse and dynamic, with a wide range of products available to meet the specific needs of different industries. As technology continues to advance, new formulations and application methods are being developed, offering improved performance and efficiency. This ongoing innovation is driving the growth of the high-temperature coating market, as industries seek more effective solutions to their heat-related challenges.

Automotive, Fireplaces Application, Aerospace, Marine, Power/Chemical Plants/Refineries, Agriculture and Construction Equipment (ACE), Others in the High-Temperature Coating- Global Market:

High-temperature coatings play a crucial role in various industries, providing essential protection and performance enhancement for equipment and structures exposed to extreme heat. In the automotive industry, these coatings are used to protect engine components, exhaust systems, and other parts that are subjected to high temperatures during operation. By reducing heat transfer and preventing thermal degradation, high-temperature coatings help improve the efficiency and longevity of automotive components, contributing to better fuel economy and reduced emissions. In fireplaces and heating applications, high-temperature coatings are used to protect metal surfaces from the intense heat generated by combustion. These coatings help prevent corrosion and oxidation, ensuring the safety and durability of fireplaces and stoves. In the aerospace industry, high-temperature coatings are critical for protecting aircraft engines, turbines, and other components from the extreme heat and pressure encountered during flight. These coatings help maintain the structural integrity and performance of aerospace components, ensuring the safety and reliability of aircraft. In the marine industry, high-temperature coatings are used to protect ship engines and exhaust systems from the corrosive effects of saltwater and high temperatures. These coatings help extend the service life of marine equipment, reducing maintenance costs and improving operational efficiency. In power plants, chemical plants, and refineries, high-temperature coatings are essential for protecting pipes, tanks, and other equipment from the harsh conditions of high heat and chemical exposure. These coatings help prevent corrosion and thermal degradation, ensuring the safe and efficient operation of industrial facilities. In agriculture and construction equipment (ACE), high-temperature coatings are used to protect machinery and components from the heat generated during operation. These coatings help improve the durability and performance of equipment, reducing downtime and maintenance costs. Other applications of high-temperature coatings include the protection of industrial ovens, furnaces, and kilns, where they help maintain thermal efficiency and prevent heat loss. Overall, high-temperature coatings are a vital component in many industries, providing essential protection and performance enhancement for equipment and structures exposed to extreme heat.

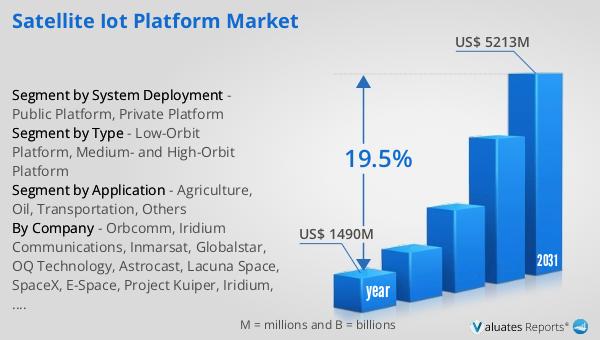

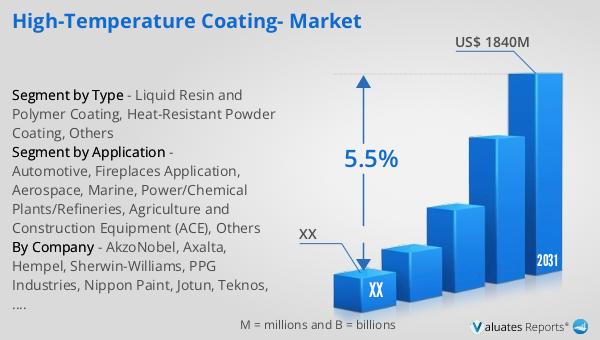

High-Temperature Coating- Global Market Outlook:

The global market for high-temperature coatings is projected to experience significant growth in the coming years. In 2024, the market was valued at approximately US$ 1,273 million, and it is expected to reach a revised size of US$ 1,840 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.5% during the forecast period from 2025 to 2031. The market is dominated by the top five players, who collectively hold a market share of about 63%. Among the various product types, liquid resin and polymer coatings represent the largest segment, accounting for a 33% share of the market. These coatings are favored for their versatility and ease of application, making them a popular choice across various industries. In terms of application, power plants, chemical plants, and refineries constitute the largest segment, occupying a 42% share of the market. The demand for high-temperature coatings in these industries is driven by the need for reliable and effective solutions to protect equipment and structures from the harsh conditions of high heat and chemical exposure. As industries continue to evolve and expand, the demand for high-temperature coatings is expected to grow, driving innovation and development in the market.

| Report Metric | Details |

| Report Name | High-Temperature Coating- Market |

| Forecasted market size in 2031 | US$ 1840 million |

| CAGR | 5.5% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | AkzoNobel, Axalta, Hempel, Sherwin-Williams, PPG Industries, Nippon Paint, Jotun, Teknos, Beijing Zhi Sheng Wei Hua Chemical Co. Ltd., Aremco, Belzona International, Korthals Lakfabriek, Hentzen Coatings, Osaka Paint, Okitsumo |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |