What is Functional Safety Systems- Global Market?

Functional safety systems are crucial components in various industries, ensuring that systems operate correctly even when they fail. These systems are designed to detect potential hazards and initiate appropriate responses to prevent accidents or mitigate their impact. The global market for functional safety systems is driven by the increasing demand for safety measures across industries such as oil and gas, automotive, and manufacturing. As industries become more automated and complex, the need for reliable safety systems becomes paramount. Functional safety systems encompass a range of technologies and solutions, including emergency shutdown systems, fire and gas detection systems, and high integrity pressure protection systems. These systems are essential for maintaining operational safety and compliance with international safety standards. The market is characterized by continuous advancements in technology, leading to more sophisticated and efficient safety solutions. As a result, companies are investing heavily in research and development to enhance the capabilities of their safety systems. The global market for functional safety systems is expected to grow steadily, driven by the increasing emphasis on safety and regulatory compliance across various industries.

Emergency Shutdown System, Combustion Management System, Fire and Gas Detection Systems, Turbomachinery Control, High Integrity Pressure Protection Systems, Others in the Functional Safety Systems- Global Market:

Emergency shutdown systems (ESD) are critical components in industrial settings, designed to safely halt operations in the event of a hazardous situation. These systems are essential in preventing accidents and minimizing damage to equipment and personnel. ESD systems are widely used in industries such as oil and gas, petrochemicals, and manufacturing, where the risk of accidents is high. Combustion management systems, on the other hand, are designed to control and optimize the combustion process in industrial boilers and furnaces. These systems ensure efficient fuel usage and reduce emissions, contributing to environmental sustainability. Fire and gas detection systems are crucial for identifying and responding to fire and gas leaks in industrial environments. These systems use advanced sensors and alarms to detect potential hazards and initiate appropriate responses, such as activating fire suppression systems or shutting down equipment. Turbomachinery control systems are used to monitor and control the operation of turbines and compressors in industrial settings. These systems ensure optimal performance and prevent equipment failure, reducing downtime and maintenance costs. High integrity pressure protection systems (HIPPS) are designed to prevent over-pressurization in pipelines and vessels, protecting equipment and personnel from potential hazards. These systems use advanced sensors and control valves to monitor pressure levels and initiate appropriate responses when necessary. Other functional safety systems include safety instrumented systems (SIS), which are used to monitor and control critical processes in industrial settings. These systems are designed to detect potential hazards and initiate appropriate responses to prevent accidents and minimize damage. Overall, functional safety systems play a vital role in ensuring the safety and reliability of industrial operations, protecting both personnel and equipment from potential hazards.

Oil, Gas and Petrochemicals, Metallurgy, Electrical Power, Metallurgical, Automotive and Rail Transportation, Medical Care, Aerospace and Defense, Others in the Functional Safety Systems- Global Market:

Functional safety systems are widely used across various industries to ensure the safety and reliability of operations. In the oil, gas, and petrochemical industries, these systems are essential for preventing accidents and minimizing the impact of hazardous events. They are used to monitor and control critical processes, such as drilling and refining, ensuring that operations are conducted safely and efficiently. In the metallurgy industry, functional safety systems are used to monitor and control processes such as smelting and casting, ensuring that operations are conducted safely and efficiently. These systems help prevent accidents and minimize the impact of hazardous events, protecting both personnel and equipment. In the electrical power industry, functional safety systems are used to monitor and control the operation of power plants and distribution networks. These systems ensure that power is generated and distributed safely and efficiently, minimizing the risk of accidents and equipment failure. In the automotive and rail transportation industries, functional safety systems are used to monitor and control critical systems such as braking and steering, ensuring that vehicles operate safely and efficiently. These systems help prevent accidents and minimize the impact of hazardous events, protecting both passengers and equipment. In the medical care industry, functional safety systems are used to monitor and control critical equipment such as ventilators and infusion pumps, ensuring that they operate safely and efficiently. These systems help prevent accidents and minimize the impact of hazardous events, protecting both patients and healthcare providers. In the aerospace and defense industries, functional safety systems are used to monitor and control critical systems such as navigation and communication, ensuring that operations are conducted safely and efficiently. These systems help prevent accidents and minimize the impact of hazardous events, protecting both personnel and equipment. Overall, functional safety systems play a vital role in ensuring the safety and reliability of operations across various industries, protecting both personnel and equipment from potential hazards.

Functional Safety Systems- Global Market Outlook:

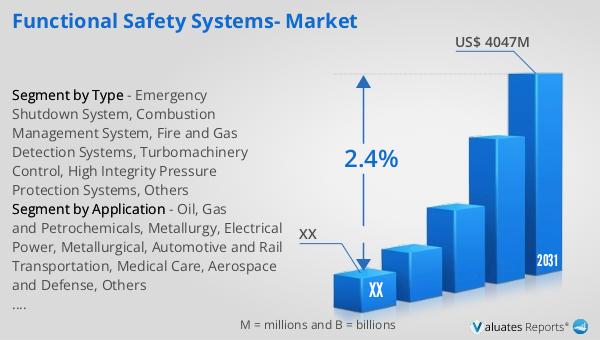

The global market for functional safety systems is projected to experience steady growth in the coming years. In 2024, the market was valued at approximately US$ 3431 million, and it is anticipated to reach a revised size of US$ 4047 million by 2031, reflecting a compound annual growth rate (CAGR) of 2.4% during the forecast period from 2025 to 2031. The market is dominated by the top three players, who collectively hold a market share exceeding 45%. Europe emerges as the largest regional market, accounting for about 38% of the global share. Among the various product types, the emergency shutdown system segment stands out as the largest, capturing approximately 50% of the market share. In terms of application, the oil, gas, and petrochemical sector is the most significant, representing around 42% of the market. This data underscores the critical role of functional safety systems in ensuring operational safety and compliance across diverse industries. As industries continue to prioritize safety and regulatory compliance, the demand for advanced functional safety systems is expected to remain robust, driving further growth in the global market.

| Report Metric | Details |

| Report Name | Functional Safety Systems- Market |

| Forecasted market size in 2031 | US$ 4047 million |

| CAGR | 2.4% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Schneider, Yokogawa, Honeywell, Rockwell Automation, ABB, Emerson Electric, Siemens, HIMA Paul Hildebrandt, SUPCON Technology, Consen Automation, Hollysys Automation, Mitsubishi Electric |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |