What is Ferro Titanium- Global Market?

Ferro Titanium is a crucial alloy in the global market, primarily composed of iron and titanium. It is widely used in various industries due to its ability to enhance the properties of metals, particularly in steelmaking. The global market for Ferro Titanium is driven by its demand in the steel industry, where it acts as a deoxidizer and grain refiner, improving the strength and durability of steel products. This alloy is also valued for its ability to remove impurities such as sulfur and oxygen from molten metals, which enhances the quality of the final product. The market is characterized by a diverse range of applications, including its use in the production of stainless steel, where it contributes to corrosion resistance. Additionally, Ferro Titanium is employed in the aerospace and automotive industries due to its lightweight and high-strength properties. The global market is influenced by factors such as technological advancements, increasing demand for high-performance materials, and the growth of end-use industries. As a result, the Ferro Titanium market is expected to experience steady growth, driven by its essential role in enhancing the performance and quality of various metal products.

Titanium Content 46%-70%, Titanium Content 25%-35%, Titanium Content 36%-45% in the Ferro Titanium- Global Market:

Ferro Titanium is available in different grades based on its titanium content, which significantly influences its application and performance in various industries. The first grade, with a titanium content ranging from 46% to 70%, is highly sought after for its superior properties. This high titanium content makes it ideal for applications requiring enhanced strength and corrosion resistance, such as in the aerospace and automotive sectors. The high-grade Ferro Titanium is also used in the production of high-performance alloys, where its ability to improve mechanical properties is crucial. The second grade, with a titanium content of 25% to 35%, is commonly used in the steelmaking industry. This grade is effective in deoxidizing and refining grain structures in steel, which enhances the overall quality and durability of the final product. It is particularly beneficial in producing stainless steel, where it contributes to improved corrosion resistance and mechanical strength. The third grade, with a titanium content of 36% to 45%, serves as a versatile option for various applications. It strikes a balance between performance and cost, making it suitable for industries that require reliable yet cost-effective solutions. This grade is often used in the production of welding electrodes and as an additive in molten metal processes. Each grade of Ferro Titanium offers unique benefits, allowing industries to select the most appropriate option based on their specific needs and requirements. The availability of different grades ensures that Ferro Titanium can cater to a wide range of applications, from high-performance alloys to cost-effective solutions for everyday industrial needs. As the demand for advanced materials continues to grow, the versatility and adaptability of Ferro Titanium make it an indispensable component in the global market.

Steelmaking, Molten Metal Additive, Others in the Ferro Titanium- Global Market:

Ferro Titanium plays a vital role in various industrial applications, particularly in steelmaking, as a molten metal additive, and in other specialized areas. In steelmaking, Ferro Titanium is primarily used as a deoxidizer and grain refiner. Its ability to remove impurities such as oxygen and sulfur from molten steel enhances the quality and mechanical properties of the final product. This results in stronger, more durable steel that is resistant to corrosion and wear. The use of Ferro Titanium in steelmaking is crucial for producing high-quality stainless steel, which is widely used in construction, automotive, and aerospace industries. As a molten metal additive, Ferro Titanium contributes to the improvement of metal properties by enhancing their strength, ductility, and resistance to corrosion. It is often added to molten metal baths to refine grain structures and improve the overall quality of the metal. This application is particularly important in the production of high-performance alloys, where precise control over metal properties is essential. In addition to steelmaking and molten metal applications, Ferro Titanium is used in other specialized areas such as the production of welding electrodes and as an additive in foundry processes. Its ability to improve the mechanical properties of metals makes it a valuable component in the manufacturing of welding electrodes, where it enhances the strength and durability of welds. In foundry processes, Ferro Titanium is used to improve the quality of castings by refining grain structures and reducing defects. The versatility of Ferro Titanium in these applications highlights its importance in the global market, where it continues to be a key material for enhancing the performance and quality of metal products.

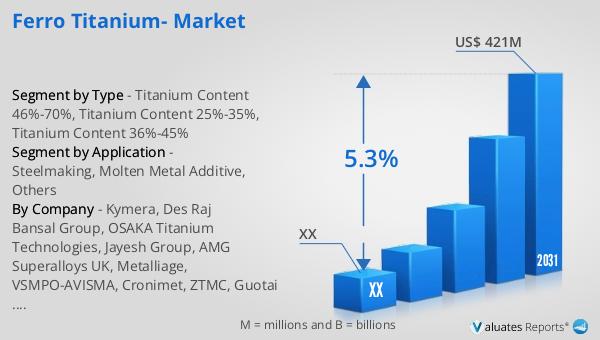

Ferro Titanium- Global Market Outlook:

The global Ferro Titanium market is projected to grow significantly, with an estimated value of $294 million in 2024, expected to reach approximately $421 million by 2031. This growth is anticipated to occur at a compound annual growth rate (CAGR) of 5.3% from 2025 to 2031. The market is dominated by the top five players, who collectively hold about 53% of the market share. The Asia-Pacific region emerges as the largest market, accounting for approximately 45% of the global share, followed by Europe and North America, which hold shares of 29% and 19%, respectively. In terms of application, steelmaking is the predominant field, representing about 91% of the market share. This dominance is attributed to the critical role Ferro Titanium plays in enhancing the quality and performance of steel products. The market's growth is driven by the increasing demand for high-performance materials in various industries, including construction, automotive, and aerospace. The ability of Ferro Titanium to improve the mechanical properties of metals, such as strength, ductility, and corrosion resistance, makes it an essential component in these industries. As the demand for advanced materials continues to rise, the Ferro Titanium market is expected to experience steady growth, driven by its indispensable role in enhancing the performance and quality of metal products.

| Report Metric | Details |

| Report Name | Ferro Titanium- Market |

| Forecasted market size in 2031 | US$ 421 million |

| CAGR | 5.3% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Kymera, Des Raj Bansal Group, OSAKA Titanium Technologies, Jayesh Group, AMG Superalloys UK, Metalliage, VSMPO-AVISMA, Cronimet, ZTMC, Guotai Industrial, Jinzhou Guangda Ferroalloy, Hengtai Special Alloy, Mottram, Metal & Alloys, Kamman Group, Mast Europe |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |