What is PUR Hot-Melt Adhesives- Global Market?

Polyurethane Reactive (PUR) Hot-Melt Adhesives are a type of adhesive that has gained significant traction in the global market due to their versatile applications and strong bonding capabilities. These adhesives are unique because they combine the benefits of hot-melt adhesives with the superior bonding strength of polyurethane. When applied, PUR hot-melt adhesives initially behave like traditional hot-melts, providing a quick set time and initial bond strength. However, they undergo a secondary curing process through a reaction with moisture in the air, which enhances their strength and durability over time. This makes them ideal for applications requiring strong, long-lasting bonds. The global market for PUR hot-melt adhesives is driven by their increasing use in various industries such as automotive, woodworking, electronics, and textiles. Their ability to bond diverse materials, including plastics, metals, and fabrics, makes them a preferred choice for manufacturers looking for reliable and efficient adhesive solutions. As industries continue to innovate and demand more robust bonding solutions, the market for PUR hot-melt adhesives is expected to grow, reflecting their critical role in modern manufacturing processes.

Liquid PUR Hot-Melt Adhesives, Solid PUR Hot-Melt Adhesives in the PUR Hot-Melt Adhesives- Global Market:

Liquid PUR hot-melt adhesives and solid PUR hot-melt adhesives are two primary forms of these versatile bonding agents, each with distinct characteristics and applications. Liquid PUR hot-melt adhesives are known for their ease of application and ability to form strong bonds with a variety of substrates. They are typically applied using specialized equipment that heats the adhesive to a liquid state, allowing it to be spread evenly across surfaces. Once applied, the adhesive cools and solidifies, forming an initial bond. The true strength of liquid PUR adhesives, however, comes from their secondary curing process, where they react with moisture in the air to form a durable, long-lasting bond. This makes them particularly useful in applications where flexibility and strength are required, such as in the automotive and textile industries. On the other hand, solid PUR hot-melt adhesives are supplied in a solid form, often as pellets or blocks, and require melting before application. These adhesives are favored for their stability and ease of storage, as they do not require special conditions to maintain their integrity. Solid PUR adhesives are often used in woodworking and furniture manufacturing, where they provide strong, reliable bonds that can withstand the stresses of daily use. Both liquid and solid PUR hot-melt adhesives offer unique advantages, and the choice between them often depends on the specific requirements of the application, such as the materials being bonded, the desired bond strength, and the environmental conditions the bond will be exposed to. As industries continue to evolve and demand more efficient and reliable bonding solutions, both liquid and solid PUR hot-melt adhesives are expected to play a crucial role in meeting these needs.

Automotive, Woodworking Furniture, Electronic, Textile, Other in the PUR Hot-Melt Adhesives- Global Market:

PUR hot-melt adhesives are widely used across various industries due to their exceptional bonding properties and versatility. In the automotive industry, these adhesives are crucial for assembling components that require strong, durable bonds. They are used in bonding interior panels, trim, and even in the assembly of electronic components within vehicles. The ability of PUR adhesives to withstand temperature fluctuations and vibrations makes them ideal for automotive applications, where reliability and safety are paramount. In the woodworking and furniture industry, PUR hot-melt adhesives are favored for their ability to bond wood and composite materials effectively. They provide strong, durable bonds that can withstand the stresses of daily use, making them ideal for furniture assembly and cabinetry. The quick setting time of these adhesives also enhances production efficiency, allowing manufacturers to produce high-quality products at a faster rate. In the electronics industry, PUR hot-melt adhesives are used to bond components that require precision and reliability. They are often used in the assembly of circuit boards and other electronic devices, where their ability to form strong, durable bonds is essential for ensuring the longevity and performance of the product. The textile industry also benefits from the use of PUR hot-melt adhesives, particularly in the production of garments and footwear. These adhesives provide strong bonds that can withstand the stresses of wear and tear, ensuring that products remain intact and durable over time. Additionally, PUR adhesives are used in other industries, such as packaging and construction, where their versatility and strength make them a preferred choice for bonding a wide range of materials. As industries continue to innovate and demand more efficient and reliable bonding solutions, the use of PUR hot-melt adhesives is expected to grow, reflecting their critical role in modern manufacturing processes.

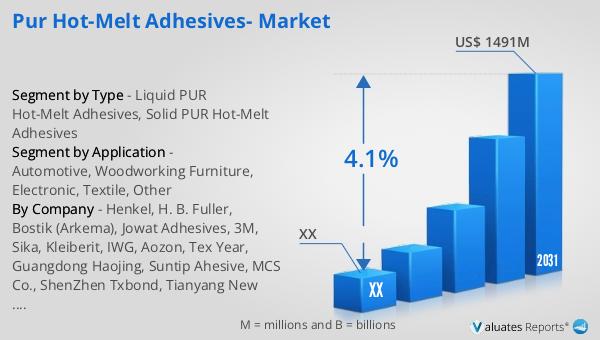

PUR Hot-Melt Adhesives- Global Market Outlook:

The global market for PUR hot-melt adhesives was valued at approximately $1,130 million in 2024, with projections indicating a growth to around $1,491 million by 2031. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.1% from 2025 to 2031. Among the key players in this market, Henkel stands out as the largest manufacturer, commanding a revenue share exceeding 32.89% in 2023. The market is characterized by a high concentration, with the top five players accounting for about 72.30% of the global revenue share. This indicates a competitive landscape where a few major companies dominate the market, leveraging their expertise and resources to maintain a stronghold. The significant market share held by these top players underscores the importance of innovation and strategic positioning in the PUR hot-melt adhesives industry. As the market continues to evolve, companies will need to focus on developing new products and expanding their applications to maintain their competitive edge. The projected growth in the market reflects the increasing demand for PUR hot-melt adhesives across various industries, driven by their superior bonding capabilities and versatility. As industries continue to seek more efficient and reliable bonding solutions, the market for PUR hot-melt adhesives is expected to expand, offering new opportunities for growth and innovation.

| Report Metric | Details |

| Report Name | PUR Hot-Melt Adhesives- Market |

| Forecasted market size in 2031 | US$ 1491 million |

| CAGR | 4.1% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Henkel, H. B. Fuller, Bostik (Arkema), Jowat Adhesives, 3M, Sika, Kleiberit, IWG, Aozon, Tex Year, Guangdong Haojing, Suntip Ahesive, MCS Co., ShenZhen Txbond, Tianyang New Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |