What is Silane Modified Polymer- Global Market?

Silane Modified Polymers (SMPs) are a unique class of hybrid materials that have gained significant traction in the global market due to their versatile applications and superior performance characteristics. These polymers are essentially a blend of organic and inorganic components, which are modified with silane groups to enhance their properties. The silane modification imparts excellent adhesion, flexibility, and durability to the polymers, making them ideal for various industrial applications. SMPs are particularly valued for their ability to cure at room temperature, forming strong bonds without the need for additional heat or catalysts. This feature not only simplifies the application process but also reduces energy consumption, making SMPs an environmentally friendly option. The global market for Silane Modified Polymers is driven by the increasing demand for high-performance adhesives and sealants across various industries, including construction, automotive, and electronics. As industries continue to seek materials that offer both performance and sustainability, the demand for SMPs is expected to grow, positioning them as a key player in the future of material science.

Viscosity < 5000, Viscosity 5000-10000, Viscosity 10000-30000, Viscosity 30000-50000, Viscosity >50000 in the Silane Modified Polymer- Global Market:

Silane Modified Polymers are categorized based on their viscosity, which significantly influences their application and performance characteristics. Viscosity < 5000 is the lowest viscosity range, making these polymers highly fluid and easy to apply. They are ideal for applications requiring thin, even coatings or where penetration into small gaps is necessary. This viscosity range is often used in applications where quick spreading and fast curing are essential, such as in certain types of coatings and sealants. Viscosity 5000-10000 represents a slightly thicker consistency, offering a balance between fluidity and body. This range is suitable for applications that require a bit more substance, such as in industrial adhesives where a moderate level of thickness is beneficial for bonding larger surfaces. Viscosity 10000-30000 is the most popular segment, accounting for a significant share of the market. This range provides a robust balance of thickness and workability, making it ideal for construction adhesives and sealants. The polymers in this range offer excellent gap-filling properties and strong adhesion, which are crucial for construction applications. Viscosity 30000-50000 is characterized by a thicker, paste-like consistency, suitable for heavy-duty applications where maximum strength and durability are required. These polymers are often used in automotive adhesives and sealants, where they provide the necessary strength to withstand the stresses and strains of vehicle operation. Finally, Viscosity >50000 represents the thickest range, used in specialized applications that require extreme durability and resistance to environmental factors. These polymers are typically used in niche markets where their unique properties can be fully utilized. Each viscosity range offers distinct advantages, allowing manufacturers to choose the right polymer for their specific needs, thereby driving innovation and efficiency across various industries.

Construction Adhesives and Sealants, Industrial Adhesives and Sealants, Automotive Adhesives and Sealants, Coating, Others in the Silane Modified Polymer- Global Market:

Silane Modified Polymers are extensively used in various sectors due to their unique properties and versatility. In the construction industry, these polymers are primarily used as adhesives and sealants. Their ability to bond with a wide range of materials, including glass, metal, and concrete, makes them indispensable in construction applications. They provide excellent weather resistance, flexibility, and durability, ensuring long-lasting performance in both indoor and outdoor environments. In industrial applications, SMPs serve as reliable adhesives and sealants, offering strong bonding capabilities and resistance to chemicals and temperature fluctuations. This makes them ideal for use in manufacturing processes where durability and reliability are paramount. In the automotive sector, Silane Modified Polymers are used as adhesives and sealants to enhance vehicle assembly and performance. They provide strong bonds that can withstand the vibrations and stresses of vehicle operation, contributing to the overall safety and longevity of the vehicle. Additionally, SMPs are used in coatings to provide protective layers that resist corrosion and wear, extending the lifespan of automotive components. Beyond these primary applications, SMPs are also used in other areas such as electronics, where their insulating properties and resistance to environmental factors are highly valued. The versatility and performance of Silane Modified Polymers make them a preferred choice across various industries, driving their demand in the global market.

Silane Modified Polymer- Global Market Outlook:

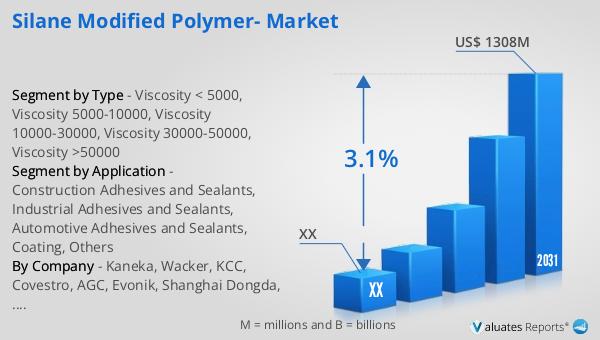

The global market for Silane Modified Polymers is projected to experience steady growth in the coming years. In 2024, the market was valued at approximately US$ 1062 million, and it is anticipated to reach a revised size of US$ 1308 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.1% during the forecast period from 2025 to 2031. The market is dominated by a few key players, with the top three companies holding a combined market share of about 54%. Among the various product types, the Viscosity 10000-30000 segment is the largest, accounting for a substantial 46% share of the market. This segment's popularity is largely due to its optimal balance of thickness and workability, making it suitable for a wide range of applications, particularly in construction. In terms of application, Construction Adhesives and Sealants represent the largest field, with a market share of approximately 41%. This dominance is driven by the increasing demand for high-performance materials in the construction industry, where SMPs are valued for their strong adhesion, flexibility, and durability. As industries continue to prioritize performance and sustainability, the demand for Silane Modified Polymers is expected to grow, solidifying their position as a key material in various applications.

| Report Metric | Details |

| Report Name | Silane Modified Polymer- Market |

| Forecasted market size in 2031 | US$ 1308 million |

| CAGR | 3.1% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Kaneka, Wacker, KCC, Covestro, AGC, Evonik, Shanghai Dongda, Risun Polymer, Huangma |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |