What is Capsule Fillers- Global Market?

Capsule fillers are essential machines in the global market, primarily used for filling empty capsules with various substances, such as powders, granules, or liquids. These machines are crucial in the pharmaceutical, nutraceutical, and other related industries, where precise dosage and efficiency are paramount. The global market for capsule fillers is driven by the increasing demand for dietary supplements and medications, as well as the growing trend of personalized medicine. Capsule fillers come in different types, including fully automatic, semi-automatic, and manual, each catering to different production needs and scales. The market is characterized by technological advancements that enhance the speed, accuracy, and flexibility of these machines, making them more efficient and user-friendly. As the demand for health and wellness products continues to rise, the capsule fillers market is expected to grow, offering opportunities for innovation and expansion. The market is also influenced by regulatory standards and the need for compliance with quality and safety guidelines, which drive manufacturers to continuously improve their products. Overall, capsule fillers play a vital role in the production process, ensuring that products meet the required standards and consumer expectations.

Fully Automatic, Semi-automatic, Manual in the Capsule Fillers- Global Market:

In the global market for capsule fillers, there are three main types of machines: fully automatic, semi-automatic, and manual. Each type serves different needs and scales of production, offering unique advantages and challenges. Fully automatic capsule fillers are the most advanced and widely used in large-scale production environments. These machines are designed to handle high volumes with minimal human intervention, making them ideal for pharmaceutical companies that require precision and efficiency. They are equipped with sophisticated technology that ensures accurate filling, sealing, and quality control, reducing the risk of errors and contamination. The fully automatic segment dominates the market, accounting for a significant share due to its efficiency and reliability. On the other hand, semi-automatic capsule fillers offer a balance between automation and manual operation. They are suitable for medium-sized production facilities that need flexibility and control over the filling process. These machines require some level of human involvement, particularly in the loading and unloading of capsules, but they still provide a high degree of accuracy and speed. Semi-automatic fillers are often used by nutraceutical companies that produce a variety of products in smaller batches. Manual capsule fillers, while less common in large-scale operations, are still valuable for small businesses and research laboratories. These machines are cost-effective and easy to operate, making them ideal for startups or companies with limited production needs. Manual fillers require more human labor and are slower compared to their automatic counterparts, but they offer greater control over the filling process, allowing for customization and experimentation. Despite their limitations, manual fillers are essential for niche markets and specialized applications where precision and customization are more important than speed. Overall, the choice between fully automatic, semi-automatic, and manual capsule fillers depends on the specific needs and goals of the business, as well as the scale of production and available resources. Each type of machine has its own set of benefits and challenges, and companies must carefully evaluate their options to determine the best fit for their operations. As the global market for capsule fillers continues to evolve, manufacturers are likely to develop new technologies and features that enhance the capabilities and efficiency of these machines, providing even more options for businesses in the future.

Pharmaceutical Company, Nutraceutical Company, Biological Company, Other in the Capsule Fillers- Global Market:

Capsule fillers are widely used across various industries, including pharmaceutical, nutraceutical, biological, and others, each with its own specific requirements and applications. In pharmaceutical companies, capsule fillers are essential for producing a wide range of medications, from over-the-counter drugs to prescription medications. These machines ensure that each capsule contains the precise dosage required, maintaining consistency and quality across batches. The pharmaceutical industry relies heavily on fully automatic capsule fillers due to their ability to handle large volumes with high accuracy and speed. In the nutraceutical industry, capsule fillers are used to produce dietary supplements, vitamins, and herbal products. This industry often requires flexibility in production, as companies may produce a variety of products in different formulations and sizes. Semi-automatic capsule fillers are popular in this sector, as they offer a balance between efficiency and customization, allowing companies to adapt to changing consumer demands. Biological companies also utilize capsule fillers for producing products such as probiotics and other biologically active substances. These products often require special handling and precise filling to maintain their efficacy and stability. Capsule fillers used in this industry must meet stringent quality and safety standards to ensure that the final product is safe for consumption. In addition to these industries, capsule fillers are also used in other sectors, such as cosmetics and food, where encapsulation is needed for specific applications. For example, in the cosmetics industry, capsule fillers may be used to produce encapsulated ingredients for skincare products, providing controlled release and enhanced stability. In the food industry, encapsulation can be used to protect sensitive ingredients or enhance the delivery of flavors and nutrients. Overall, the versatility and efficiency of capsule fillers make them indispensable tools in various industries, enabling companies to produce high-quality products that meet consumer expectations and regulatory requirements. As the demand for health and wellness products continues to grow, the use of capsule fillers is expected to expand, driving innovation and development in this market.

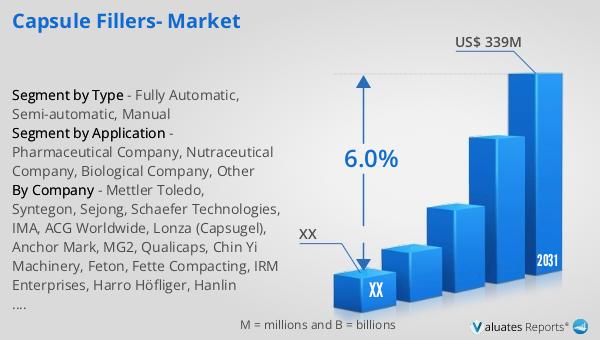

Capsule Fillers- Global Market Outlook:

The global market for capsule fillers is projected to grow significantly in the coming years. In 2024, the market was valued at approximately US$ 227 million, and it is anticipated to reach a revised size of US$ 339 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.0% during the forecast period from 2025 to 2031. The market is dominated by the top five players, who collectively hold about 28% of the market share. The Asia-Pacific region is the largest market for capsule fillers, accounting for approximately 43% of the global share, followed by Europe and North America, with shares of 27% and 21%, respectively. In terms of product type, fully automatic capsule fillers are the most prevalent, occupying a substantial 88% share of the market. This dominance is due to their efficiency and ability to handle large-scale production with minimal human intervention. When it comes to application, pharmaceutical companies are the largest users of capsule fillers, representing about 84% of the market share. This is largely because the pharmaceutical industry requires precise and efficient production processes to meet the high demand for medications and ensure compliance with stringent regulatory standards. Overall, the capsule fillers market is poised for growth, driven by increasing demand across various industries and regions.

| Report Metric | Details |

| Report Name | Capsule Fillers- Market |

| Forecasted market size in 2031 | US$ 339 million |

| CAGR | 6.0% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Mettler Toledo, Syntegon, Sejong, Schaefer Technologies, IMA, ACG Worldwide, Lonza (Capsugel), Anchor Mark, MG2, Qualicaps, Chin Yi Machinery, Feton, Fette Compacting, IRM Enterprises, Harro Höfliger, Hanlin Hangyu Industrial, Zhejiang Fuchang Machinery, Adinath International |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |