What is Industrial Gaskets- Global Market?

Industrial gaskets are essential components used in various industries to prevent leaks and ensure the smooth operation of machinery and equipment. These gaskets are designed to fill the space between two or more mating surfaces, thereby preventing the escape of fluids or gases. The global market for industrial gaskets is vast and diverse, catering to numerous sectors such as oil and gas, chemical, automotive, and more. The demand for industrial gaskets is driven by the need for efficient sealing solutions that can withstand extreme temperatures, pressures, and chemical exposures. As industries continue to expand and modernize, the requirement for high-performance gaskets is on the rise. This market is characterized by a wide range of products, including metallic, non-metallic, and semi-metallic gaskets, each offering unique properties and advantages. The global industrial gaskets market is also influenced by technological advancements, which have led to the development of innovative materials and designs that enhance the durability and efficiency of gaskets. As a result, manufacturers are continually investing in research and development to meet the evolving needs of various industries. The market's growth is further supported by the increasing focus on energy efficiency and environmental sustainability, prompting industries to adopt advanced sealing solutions.

Metallic, Non-Metallic, Semi-Metallic in the Industrial Gaskets- Global Market:

Industrial gaskets are categorized into three main types: metallic, non-metallic, and semi-metallic, each serving specific applications based on their material properties and performance characteristics. Metallic gaskets are made from metals or metal alloys, offering excellent strength and durability. They are ideal for high-pressure and high-temperature applications, such as in the oil and gas industry, where they provide reliable sealing under extreme conditions. Common types of metallic gaskets include ring joint gaskets, spiral wound gaskets, and corrugated gaskets. These gaskets are known for their ability to withstand harsh environments and are often used in applications where chemical resistance is crucial. Non-metallic gaskets, on the other hand, are made from materials such as rubber, PTFE, graphite, and other composites. They are suitable for applications where flexibility and compressibility are required. Non-metallic gaskets are commonly used in the food and beverage industry, pharmaceuticals, and other sectors where contamination must be avoided. They offer excellent sealing properties and are resistant to a wide range of chemicals. Semi-metallic gaskets combine the properties of both metallic and non-metallic gaskets, providing a balance of strength and flexibility. These gaskets are often used in applications where a high degree of sealing is required, but the conditions are not as extreme as those for metallic gaskets. Spiral wound gaskets and metal jacketed gaskets are examples of semi-metallic gaskets, offering versatility and reliability in various industrial applications. The choice of gasket type depends on several factors, including the nature of the fluid or gas being sealed, the operating temperature and pressure, and the specific requirements of the application. As industries continue to evolve, the demand for specialized gaskets that can meet stringent performance criteria is increasing. Manufacturers are focusing on developing advanced materials and designs to enhance the performance and longevity of gaskets, ensuring they can withstand the demands of modern industrial processes. The global market for industrial gaskets is highly competitive, with numerous players offering a wide range of products to cater to diverse industry needs. As a result, companies are investing in research and development to innovate and improve their product offerings, ensuring they remain competitive in this dynamic market.

Oil and Gas, Chemical and Petrochemical, Power Generation, Automotive, Food and Beverage, Medical and Pharmaceutical, Aerospace and Defense, Others in the Industrial Gaskets- Global Market:

Industrial gaskets play a crucial role in various sectors, ensuring the efficient and safe operation of equipment and machinery. In the oil and gas industry, gaskets are essential for sealing pipelines, valves, and other equipment, preventing leaks and ensuring the safe transport of oil and gas. They are designed to withstand high pressures and temperatures, making them ideal for use in harsh environments. In the chemical and petrochemical industries, gaskets are used to seal reactors, pumps, and other equipment, preventing the escape of hazardous chemicals and ensuring the safety of workers and the environment. The power generation sector also relies heavily on industrial gaskets to ensure the efficient operation of turbines, boilers, and other equipment. Gaskets help maintain the integrity of these systems, preventing leaks and ensuring optimal performance. In the automotive industry, gaskets are used in engines, transmissions, and other components to prevent fluid leaks and ensure the smooth operation of vehicles. They are designed to withstand high temperatures and pressures, ensuring the reliability and longevity of automotive systems. The food and beverage industry also relies on gaskets to ensure the safe and hygienic processing of food products. Gaskets are used in equipment such as mixers, pumps, and valves, preventing contamination and ensuring the quality of food products. In the medical and pharmaceutical industries, gaskets are used in equipment such as autoclaves, sterilizers, and other devices to ensure the safe and effective processing of medical products. They are designed to withstand high temperatures and pressures, ensuring the reliability and safety of medical equipment. The aerospace and defense industries also rely on gaskets to ensure the safe and efficient operation of aircraft and other equipment. Gaskets are used in engines, fuel systems, and other components, preventing leaks and ensuring the reliability and safety of aerospace systems. Other industries, such as water treatment, pulp and paper, and mining, also rely on industrial gaskets to ensure the efficient and safe operation of equipment and processes. As industries continue to evolve and modernize, the demand for high-performance gaskets is increasing, driving innovation and growth in the global industrial gaskets market.

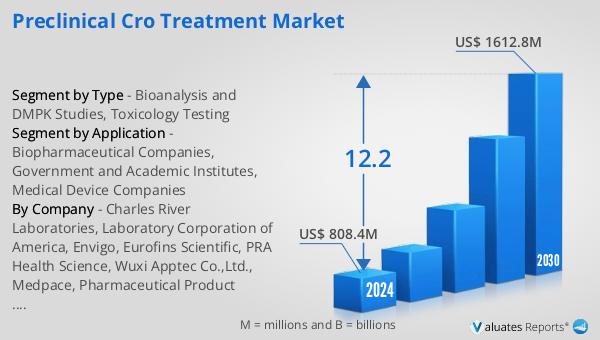

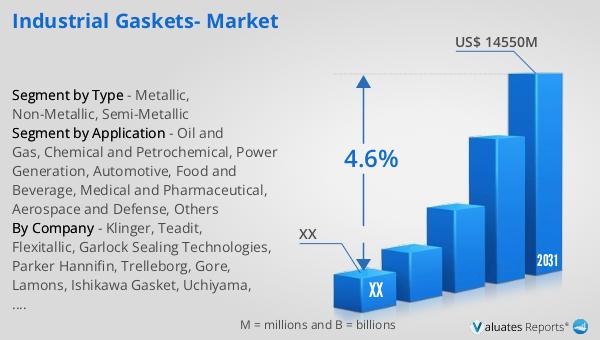

Industrial Gaskets- Global Market Outlook:

The global industrial gaskets market is poised for significant growth in the coming years. In 2024, the market was valued at approximately US$ 10,640 million, and it is projected to reach an adjusted size of US$ 14,550 million by 2031, with a compound annual growth rate (CAGR) of 4.6% during the forecast period from 2025 to 2031. The market is characterized by a high level of competition, with the top five players holding a combined market share of about 22%. The Asia-Pacific region is the largest market for industrial gaskets, accounting for approximately 48% of the global market share. This is followed by North America and Europe, with market shares of 23% and 21%, respectively. The automotive industry is the largest application segment for industrial gaskets, representing around 20% of the total market share. This is due to the increasing demand for vehicles and the need for reliable sealing solutions in automotive systems. The growth of the industrial gaskets market is driven by several factors, including the expansion of key industries such as oil and gas, chemical, and automotive, as well as the increasing focus on energy efficiency and environmental sustainability. As industries continue to evolve and modernize, the demand for high-performance gaskets is expected to rise, driving innovation and growth in the global industrial gaskets market.

| Report Metric | Details |

| Report Name | Industrial Gaskets- Market |

| Forecasted market size in 2031 | US$ 14550 million |

| CAGR | 4.6% |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Klinger, Teadit, Flexitallic, Garlock Sealing Technologies, Parker Hannifin, Trelleborg, Gore, Lamons, Ishikawa Gasket, Uchiyama, James Walker, Goodrich Gasket, Denver Rubber Company, Smith Gaskets, VED Srl, Donit Tesnit D.O.O, Centauro Srl, Davlyn Group, IGP Engineers, Temac, Leader Gasket Technologies, Carrara SpA, Yantai Ishikawa Sealing Technology, Shanghai Novus, Jinzhou Guanghe Sealing |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |