What is Global Household Electric Egg Steamer Market?

The Global Household Electric Egg Steamer Market refers to the worldwide industry focused on the production, distribution, and sale of electric devices designed specifically for steaming eggs. These appliances are becoming increasingly popular due to their convenience, efficiency, and ability to cook eggs perfectly every time. They cater to a variety of consumer needs, from busy professionals looking for a quick breakfast solution to health-conscious individuals seeking a low-fat cooking method. The market encompasses a range of products, from basic single-layer steamers to more advanced multi-layer models with additional features like timers and automatic shut-off functions. The growth of this market is driven by rising consumer demand for easy-to-use kitchen gadgets, increasing awareness about healthy eating habits, and the expanding middle class in developing countries. As more households seek to simplify their cooking processes, the demand for electric egg steamers is expected to continue rising.

Single Layer Egg Steamer, Double Layer Egg Steamer in the Global Household Electric Egg Steamer Market:

Single Layer Egg Steamers and Double Layer Egg Steamers are two primary types of products within the Global Household Electric Egg Steamer Market. Single Layer Egg Steamers are designed to cook a smaller number of eggs, typically up to six at a time. These models are compact, making them ideal for individuals or small families with limited kitchen space. They are straightforward to use, often featuring a simple on/off switch and a water measuring cup to ensure the right amount of steam is generated. Single Layer Egg Steamers are perfect for those who want a quick and easy way to prepare eggs without the hassle of boiling water on the stove. On the other hand, Double Layer Egg Steamers offer greater capacity and versatility. These models can steam up to twelve eggs simultaneously, making them suitable for larger families or those who entertain guests frequently. The double-layer design allows for the simultaneous cooking of different types of food, such as vegetables or dumplings, alongside the eggs. This multifunctionality makes Double Layer Egg Steamers a valuable addition to any kitchen. They often come with more advanced features, such as digital timers, multiple cooking modes, and automatic shut-off functions, providing users with greater control over the cooking process. Both types of egg steamers are designed to save time and energy, offering a convenient solution for preparing healthy meals. The choice between a Single Layer and Double Layer Egg Steamer ultimately depends on the user's needs and preferences. While Single Layer models are more affordable and space-efficient, Double Layer models offer greater capacity and functionality. As the Global Household Electric Egg Steamer Market continues to grow, manufacturers are likely to introduce new features and innovations to meet the evolving demands of consumers.

Online Sales, Offline Sales in the Global Household Electric Egg Steamer Market:

The usage of Global Household Electric Egg Steamers can be categorized into two main sales channels: Online Sales and Offline Sales. Online Sales have become increasingly popular due to the convenience and accessibility they offer. Consumers can browse a wide range of products from the comfort of their homes, compare prices, read reviews, and make purchases with just a few clicks. E-commerce platforms like Amazon, eBay, and specialized kitchen appliance websites have made it easier for consumers to find and purchase electric egg steamers. Online Sales also provide an opportunity for manufacturers to reach a global audience, expanding their market reach beyond geographical boundaries. Additionally, online platforms often offer discounts, promotions, and bundle deals, making it an attractive option for price-sensitive consumers. On the other hand, Offline Sales involve purchasing products from physical retail stores such as supermarkets, department stores, and specialty kitchen appliance shops. This traditional sales channel allows consumers to see and touch the products before making a purchase, providing a tactile shopping experience that online platforms cannot offer. Offline Sales also benefit from the immediate availability of products, eliminating the waiting time associated with shipping. Retail stores often have knowledgeable staff who can provide personalized recommendations and assistance, enhancing the overall shopping experience. Moreover, offline sales channels can build customer trust through face-to-face interactions and after-sales support. Both Online and Offline Sales channels play a crucial role in the distribution of Global Household Electric Egg Steamers. While Online Sales offer convenience and a broader selection, Offline Sales provide a hands-on shopping experience and immediate product availability. The choice between these sales channels depends on individual preferences, with some consumers valuing the ease of online shopping and others preferring the assurance of in-store purchases. As the market continues to evolve, a hybrid approach that combines the strengths of both channels may emerge, offering consumers the best of both worlds.

Global Household Electric Egg Steamer Market Outlook:

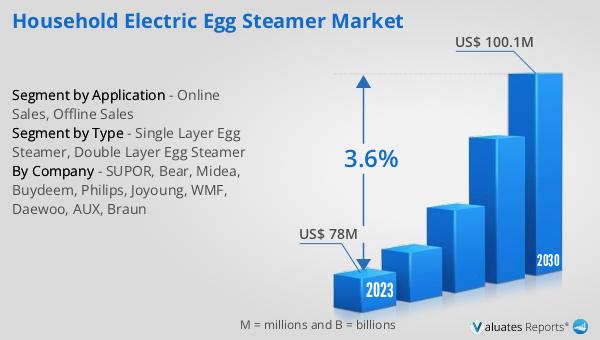

The global Household Electric Egg Steamer market was valued at US$ 78 million in 2023 and is anticipated to reach US$ 100.1 million by 2030, witnessing a CAGR of 3.6% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for the industry, driven by increasing consumer demand for convenient and efficient kitchen appliances. The rising popularity of electric egg steamers can be attributed to their ability to simplify the cooking process, making it easier for individuals to prepare healthy meals quickly. As more households adopt these appliances, the market is expected to expand further, offering new opportunities for manufacturers and retailers. The projected growth also reflects the broader trend towards automation and smart home technologies, as consumers seek to streamline their daily routines with innovative gadgets. With a compound annual growth rate of 3.6%, the Global Household Electric Egg Steamer Market is poised for sustained development, highlighting the ongoing shift towards modern, time-saving kitchen solutions.

| Report Metric | Details |

| Report Name | Household Electric Egg Steamer Market |

| Accounted market size in 2023 | US$ 78 million |

| Forecasted market size in 2030 | US$ 100.1 million |

| CAGR | 3.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | SUPOR, Bear, Midea, Buydeem, Philips, Joyoung, WMF, Daewoo, AUX, Braun |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |