What is Welding Protection Glasses - Global Market?

Welding protection glasses are an essential safety tool in various industries where welding activities are prevalent. These glasses are designed to protect the eyes from the intense light and heat generated during welding processes, as well as from harmful ultraviolet (UV) and infrared (IR) radiation. The global market for welding protection glasses is driven by the increasing demand for safety equipment in industries such as automotive, construction, and manufacturing. As awareness about workplace safety continues to grow, more companies are investing in high-quality protective gear to ensure the well-being of their workers. The market is characterized by a wide range of products, including glasses with different shade numbers to suit various welding applications. Technological advancements have also led to the development of more durable and comfortable glasses, enhancing user experience and safety. With the rise in industrial activities worldwide, the demand for welding protection glasses is expected to continue growing, making it a vital component of occupational safety equipment.

Shade Number 3, Shade Number 5 in the Welding Protection Glasses - Global Market:

Shade numbers in welding protection glasses indicate the level of darkness provided by the lenses, which is crucial for protecting the eyes from the bright light produced during welding. Shade Number 3 and Shade Number 5 are among the most commonly used shades in the global market, each serving specific purposes. Shade Number 3 glasses are typically used for torch soldering and brazing, where the light intensity is lower compared to other welding processes. These glasses provide adequate protection while allowing enough visibility for precision work. They are ideal for tasks that require a clear view of the workpiece without compromising eye safety. On the other hand, Shade Number 5 glasses are used for gas welding and cutting operations. These processes generate more intense light, necessitating a darker lens to protect the eyes effectively. Shade Number 5 glasses offer a balance between protection and visibility, making them suitable for a variety of welding tasks. The choice between Shade Number 3 and Shade Number 5 depends on the specific welding application and the intensity of light involved. In the global market, manufacturers offer a range of welding protection glasses with different shade numbers to cater to the diverse needs of industries. The availability of these options allows workers to select the appropriate level of protection based on their specific tasks, ensuring both safety and efficiency. As industries continue to prioritize worker safety, the demand for welding protection glasses with varying shade numbers is expected to rise, driving innovation and growth in the market.

Automotive, Construction, Food Industry, Mining in the Welding Protection Glasses - Global Market:

Welding protection glasses play a crucial role in several industries, including automotive, construction, food, and mining, where welding activities are integral to operations. In the automotive industry, welding is used extensively in the manufacturing and repair of vehicles. Welding protection glasses are essential for safeguarding workers from the intense light and heat produced during welding processes, ensuring their safety and productivity. In the construction industry, welding is a common activity in building infrastructure and structures. Workers rely on welding protection glasses to shield their eyes from harmful radiation and flying debris, reducing the risk of eye injuries. The food industry also utilizes welding for equipment maintenance and repair. Welding protection glasses are vital for protecting workers from potential hazards while ensuring compliance with safety regulations. In the mining industry, welding is used for equipment fabrication and repair. The harsh conditions in mining environments make welding protection glasses indispensable for protecting workers from the intense light and heat generated during welding operations. Across these industries, the use of welding protection glasses is not only a safety requirement but also a means to enhance productivity by minimizing the risk of accidents and injuries. As industries continue to evolve and prioritize worker safety, the demand for high-quality welding protection glasses is expected to grow, driving advancements in safety technology and product innovation.

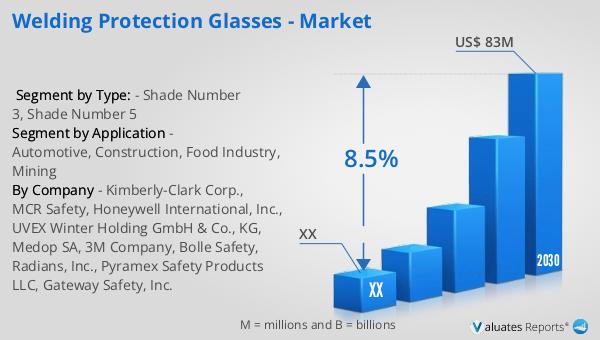

Welding Protection Glasses - Global Market Outlook:

The global market for welding protection glasses was valued at approximately US$ 20 million in 2023. This market is projected to experience significant growth, with expectations to reach a revised size of US$ 83 million by 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 8.5% during the forecast period from 2024 to 2030. The increasing demand for welding protection glasses is driven by the rising awareness of workplace safety and the need for protective equipment in various industries. As more companies recognize the importance of safeguarding their workers, the investment in high-quality welding protection glasses is expected to rise. The market's expansion is also supported by technological advancements that have led to the development of more durable and comfortable glasses, enhancing user experience and safety. With the continued growth of industrial activities worldwide, the demand for welding protection glasses is anticipated to increase, making it a vital component of occupational safety equipment. This market outlook highlights the importance of welding protection glasses in ensuring worker safety and the potential for growth in the coming years.

| Report Metric | Details |

| Report Name | Welding Protection Glasses - Market |

| Forecasted market size in 2030 | US$ 83 million |

| CAGR | 8.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Kimberly-Clark Corp., MCR Safety, Honeywell International, Inc., UVEX Winter Holding GmbH & Co., KG, Medop SA, 3M Company, Bolle Safety, Radians, Inc., Pyramex Safety Products LLC, Gateway Safety, Inc. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |