What is End Facing and Beveling Machine (EFBM) - Global Market?

End Facing and Beveling Machines (EFBM) are specialized tools used in various industries to prepare the ends of pipes and tubes for welding or joining. These machines are essential in ensuring that the ends of pipes are smooth and properly angled, which is crucial for creating strong and leak-proof joints. The global market for EFBM is driven by the increasing demand for efficient and precise pipe preparation in industries such as oil and gas, power generation, and pipeline construction. These machines come in different types, including stationary and portable models, each designed to meet specific operational needs. Stationary machines are typically used in manufacturing settings where high-volume production is required, while portable machines are favored in field operations due to their mobility and ease of use. The market is characterized by technological advancements that enhance the precision and efficiency of these machines, making them indispensable in modern industrial applications. As industries continue to expand and modernize, the demand for EFBM is expected to grow, reflecting the ongoing need for reliable and efficient pipe preparation solutions.

Stationary Machines with Rotary Cutters, Portable Machines with Rotary Cutters in the End Facing and Beveling Machine (EFBM) - Global Market:

Stationary machines with rotary cutters are a staple in industrial settings where precision and consistency are paramount. These machines are designed to handle large volumes of work, making them ideal for manufacturing plants and workshops that require high throughput. The rotary cutters in these machines are engineered to deliver precise cuts and bevels, ensuring that each pipe or tube end is prepared to exact specifications. This precision is crucial in industries where even the slightest deviation can lead to significant issues, such as leaks or structural weaknesses. Stationary machines are often equipped with advanced features like automated controls and digital interfaces, allowing operators to program specific cutting parameters and monitor the process in real-time. This level of automation not only enhances efficiency but also reduces the likelihood of human error, leading to higher quality outputs. On the other hand, portable machines with rotary cutters offer flexibility and convenience, making them ideal for field operations. These machines are lightweight and easy to transport, allowing technicians to bring the equipment directly to the job site. This is particularly beneficial in industries like pipeline construction and maintenance, where pipes are often located in remote or hard-to-reach areas. Portable machines are designed to be user-friendly, with intuitive controls that enable operators to quickly set up and execute cutting tasks. Despite their compact size, these machines are capable of delivering precise cuts and bevels, ensuring that the quality of work is not compromised. The versatility of portable machines makes them a valuable asset in situations where mobility and adaptability are required. Both stationary and portable machines play a crucial role in the global EFBM market, catering to the diverse needs of industries that rely on precise pipe preparation. As technology continues to evolve, these machines are expected to become even more efficient and user-friendly, further driving their adoption across various sectors.

Pipeline Construction, Oil and Gas, Power Generation in the End Facing and Beveling Machine (EFBM) - Global Market:

End Facing and Beveling Machines (EFBM) are extensively used in pipeline construction, oil and gas, and power generation industries due to their ability to prepare pipes and tubes for welding and joining with high precision. In pipeline construction, these machines are essential for ensuring that the ends of pipes are smooth and properly beveled, which is crucial for creating strong and leak-proof joints. The ability to deliver precise cuts and bevels is particularly important in this industry, as pipelines often transport hazardous materials that require secure and reliable connections. EFBM are also widely used in the oil and gas industry, where they play a critical role in the construction and maintenance of pipelines, refineries, and other infrastructure. The harsh environments and demanding conditions in this industry require equipment that can deliver consistent and reliable performance, making EFBM an indispensable tool for ensuring the integrity of pipe connections. In the power generation sector, EFBM are used to prepare pipes and tubes for the construction and maintenance of power plants and other facilities. The precision and efficiency of these machines are crucial in this industry, where even minor defects in pipe connections can lead to significant operational issues. The ability to deliver high-quality cuts and bevels ensures that the pipes and tubes used in power generation facilities are fit for purpose and capable of withstanding the demanding conditions they are subjected to. Overall, the use of EFBM in these industries highlights their importance in ensuring the safety, reliability, and efficiency of critical infrastructure.

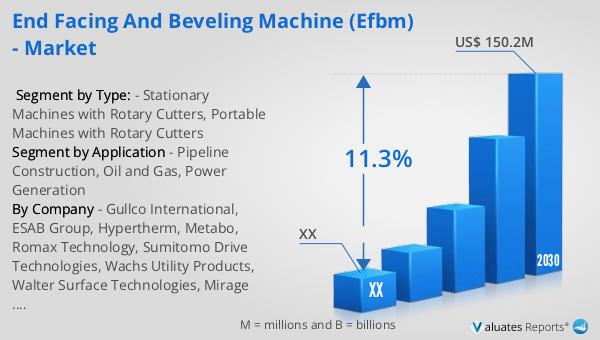

End Facing and Beveling Machine (EFBM) - Global Market Outlook:

The global market for End Facing and Beveling Machines (EFBM) was valued at approximately US$ 68 million in 2023. It is projected to expand significantly, reaching an estimated size of US$ 150.2 million by 2030, with a compound annual growth rate (CAGR) of 11.3% during the forecast period from 2024 to 2030. This growth reflects the increasing demand for efficient and precise pipe preparation solutions across various industries. In North America, the market for EFBM is also expected to experience substantial growth, although specific figures for 2023 and 2030 are not provided. The anticipated growth in this region underscores the importance of EFBM in supporting industrial activities that require high-quality pipe and tube preparation. The robust growth forecast for the global EFBM market highlights the ongoing need for advanced machinery that can deliver precise and reliable performance in demanding industrial environments. As industries continue to evolve and modernize, the demand for EFBM is expected to rise, driven by the need for efficient and effective solutions for pipe preparation.

| Report Metric | Details |

| Report Name | End Facing and Beveling Machine (EFBM) - Market |

| Forecasted market size in 2030 | US$ 150.2 million |

| CAGR | 11.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Gullco International, ESAB Group, Hypertherm, Metabo, Romax Technology, Sumitomo Drive Technologies, Wachs Utility Products, Walter Surface Technologies, Mirage Machines, Esco Tool |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |