What is Bead Contact Pressure Testing Machine (BCM) - Global Market?

The Bead Contact Pressure Testing Machine (BCM) is a specialized device used to measure the pressure distribution across the bead area of a tire. This machine plays a crucial role in ensuring the safety and performance of tires by providing accurate data on how the tire bead interacts with the rim. The bead area is critical because it is where the tire seals against the rim, and any irregularities in pressure distribution can lead to issues such as air leaks or tire blowouts. By using a BCM, manufacturers can optimize the design and materials of the tire bead to enhance performance and safety. The global market for BCMs is driven by the increasing demand for high-performance tires in various industries, including automotive and aerospace. As safety standards become more stringent, the need for precise testing equipment like the BCM becomes even more essential. The market is characterized by technological advancements that improve the accuracy and efficiency of these machines, making them indispensable tools in tire manufacturing and quality assurance processes.

Static BCM, Dynamic BCM in the Bead Contact Pressure Testing Machine (BCM) - Global Market:

Static Bead Contact Pressure Testing Machines (Static BCM) and Dynamic Bead Contact Pressure Testing Machines (Dynamic BCM) are two primary types of BCMs used in the global market, each serving distinct purposes in tire testing and development. Static BCMs are designed to measure the pressure distribution of a tire bead when the tire is stationary. This type of testing is crucial for understanding how the tire bead interacts with the rim under non-moving conditions, which can reveal potential issues related to the tire's fit and seal. Static BCMs are often used in the initial stages of tire design and development, allowing manufacturers to make necessary adjustments before moving on to more dynamic testing. These machines provide detailed insights into the uniformity of pressure distribution, helping to identify any areas of concern that could lead to air leaks or compromised performance. On the other hand, Dynamic BCMs are used to assess the pressure distribution of a tire bead while the tire is in motion. This type of testing is essential for understanding how the tire performs under real-world conditions, where factors such as speed, load, and road surface can significantly impact the pressure distribution across the bead area. Dynamic BCMs simulate these conditions, providing valuable data that can be used to optimize tire design for enhanced performance and safety. The global market for both Static and Dynamic BCMs is driven by the increasing demand for high-performance tires that meet stringent safety and performance standards. As tire manufacturers strive to develop products that offer superior performance and safety, the need for advanced testing equipment like Static and Dynamic BCMs continues to grow. These machines are equipped with sophisticated sensors and software that provide precise measurements and detailed analysis, enabling manufacturers to make informed decisions about tire design and materials. The integration of advanced technologies such as artificial intelligence and machine learning into BCMs is also contributing to the growth of the market, as these technologies enhance the accuracy and efficiency of testing processes. Overall, the global market for Static and Dynamic BCMs is characterized by continuous innovation and technological advancements, driven by the need for high-quality tires that meet the demands of modern vehicles and consumers.

Automotive, Aerospace in the Bead Contact Pressure Testing Machine (BCM) - Global Market:

The Bead Contact Pressure Testing Machine (BCM) finds significant applications in the automotive and aerospace industries, where tire performance and safety are of paramount importance. In the automotive sector, BCMs are used extensively in the design and testing of tires for passenger vehicles, commercial trucks, and high-performance sports cars. The ability to accurately measure the pressure distribution across the tire bead is crucial for ensuring that tires provide optimal grip, handling, and safety. Automotive manufacturers rely on BCMs to test tires under various conditions, including different speeds, loads, and road surfaces, to ensure that they meet the required performance standards. The data obtained from BCM testing helps manufacturers optimize tire design, materials, and construction, leading to improved fuel efficiency, reduced road noise, and enhanced overall performance. In the aerospace industry, BCMs are used to test aircraft tires, which are subject to extreme conditions during takeoff, landing, and taxiing. The pressure distribution across the tire bead is critical for ensuring that aircraft tires can withstand the high loads and stresses they encounter during operation. BCMs provide valuable data that helps aerospace manufacturers design tires that offer superior performance, durability, and safety. The use of BCMs in the aerospace industry is driven by the need to comply with stringent safety regulations and standards, as well as the demand for tires that can perform reliably in challenging environments. The global market for BCMs in the automotive and aerospace industries is characterized by a focus on innovation and technological advancements, as manufacturers seek to develop tires that offer enhanced performance and safety. The integration of advanced technologies such as artificial intelligence and machine learning into BCMs is also contributing to the growth of the market, as these technologies enable more accurate and efficient testing processes. Overall, the use of BCMs in the automotive and aerospace industries is essential for ensuring that tires meet the highest standards of performance and safety, and the global market for these machines is expected to continue growing as demand for high-quality tires increases.

Bead Contact Pressure Testing Machine (BCM) - Global Market Outlook:

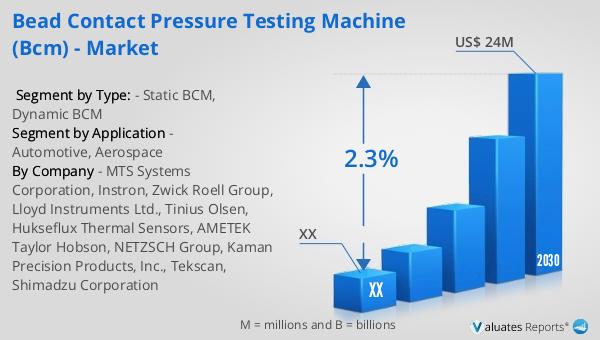

The global market outlook for Bead Contact Pressure Testing Machines (BCM) indicates a valuation of approximately $26 million in 2023. However, projections suggest a slight decrease, with the market expected to adjust to a size of $24 million by 2030, reflecting a compound annual growth rate (CAGR) of 2.3% during the forecast period from 2024 to 2030. This trend suggests a moderate contraction in the market size, possibly due to evolving industry dynamics or technological advancements that may influence demand. In North America, the market for BCMs was valued at an undisclosed amount in 2023, with expectations of reaching a certain value by 2030, maintaining a specific CAGR throughout the forecast period. This regional market outlook highlights the importance of BCMs in industries such as automotive and aerospace, where precision and safety are critical. The anticipated changes in market size and growth rates underscore the need for continuous innovation and adaptation to meet the evolving demands of these industries. As manufacturers strive to enhance tire performance and safety, the role of BCMs remains vital, driving the need for advanced testing solutions that can provide accurate and reliable data.

| Report Metric | Details |

| Report Name | Bead Contact Pressure Testing Machine (BCM) - Market |

| Forecasted market size in 2030 | US$ 24 million |

| CAGR | 2.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | MTS Systems Corporation, Instron, Zwick Roell Group, Lloyd Instruments Ltd., Tinius Olsen, Hukseflux Thermal Sensors, AMETEK Taylor Hobson, NETZSCH Group, Kaman Precision Products, Inc., Tekscan, Shimadzu Corporation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |