What is Medical Device PCB - Global Market?

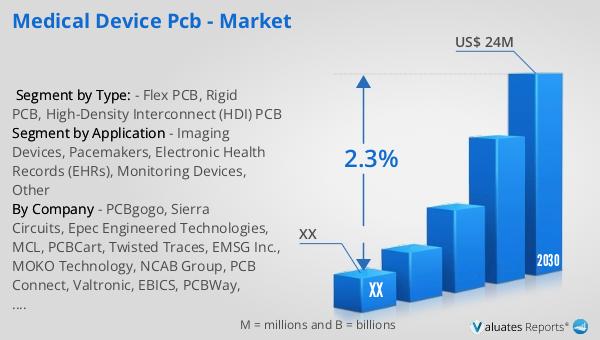

Medical Device PCBs, or Printed Circuit Boards, are crucial components in the healthcare industry, serving as the backbone for a wide range of medical devices. These PCBs are specifically designed to meet the stringent requirements of medical applications, ensuring reliability, precision, and safety. The global market for Medical Device PCBs is a dynamic and evolving sector, driven by advancements in medical technology and the increasing demand for innovative healthcare solutions. In 2023, the market was valued at approximately US$ 26 million, reflecting its significant role in the medical device industry. However, projections indicate a slight contraction, with the market expected to adjust to a size of US$ 24 million by 2030, growing at a compound annual growth rate (CAGR) of 2.3% from 2024 to 2030. This market is integral to the broader medical device industry, which was estimated at US$ 603 billion in 2023 and is anticipated to grow at a CAGR of 5% over the next six years. The demand for Medical Device PCBs is fueled by the need for advanced diagnostic and therapeutic equipment, which relies heavily on sophisticated electronic components to function effectively. As healthcare technology continues to advance, the role of PCBs in medical devices will remain pivotal, supporting innovations that enhance patient care and treatment outcomes.

Flex PCB, Rigid PCB, High-Density Interconnect (HDI) PCB in the Medical Device PCB - Global Market:

Flex PCBs, Rigid PCBs, and High-Density Interconnect (HDI) PCBs are three critical types of printed circuit boards used in the medical device industry, each offering unique benefits and applications. Flex PCBs are known for their flexibility and ability to fit into compact spaces, making them ideal for wearable medical devices and implants. Their lightweight and bendable nature allow for innovative designs that can conform to the human body, providing comfort and functionality. Flex PCBs are often used in devices like hearing aids, pacemakers, and other implantable medical devices where space is limited, and reliability is paramount. They offer excellent resistance to vibrations and mechanical stress, ensuring long-term performance in demanding environments. Rigid PCBs, on the other hand, are characterized by their solid and inflexible structure, providing a stable platform for electronic components. These PCBs are commonly used in larger medical devices such as imaging equipment, where durability and precision are essential. Rigid PCBs offer high reliability and are capable of supporting complex circuitry, making them suitable for devices that require robust performance and accuracy. They are often found in MRI machines, CT scanners, and other diagnostic equipment that demand precise electronic control. High-Density Interconnect (HDI) PCBs represent the cutting edge of PCB technology, offering increased circuit density and miniaturization. HDI PCBs are used in advanced medical devices that require high performance in a compact form factor. These PCBs enable the integration of more components in a smaller area, allowing for the development of sophisticated medical devices with enhanced functionality. HDI PCBs are crucial in the development of portable and handheld medical devices, where space and weight are critical considerations. They support the trend towards miniaturization in the medical field, enabling the creation of devices that are not only powerful but also user-friendly and easy to handle. The global market for Medical Device PCBs is driven by the increasing demand for these advanced PCB technologies, as they enable the development of innovative medical devices that improve patient care and treatment outcomes. As the medical device industry continues to evolve, the role of Flex, Rigid, and HDI PCBs will remain essential, supporting the creation of cutting-edge healthcare solutions that meet the needs of patients and healthcare providers worldwide.

Imaging Devices, Pacemakers, Electronic Health Records (EHRs), Monitoring Devices, Other in the Medical Device PCB - Global Market:

Medical Device PCBs play a vital role in various healthcare applications, including imaging devices, pacemakers, electronic health records (EHRs), monitoring devices, and more. In imaging devices, PCBs are essential for the precise control and processing of electronic signals, enabling the accurate capture and interpretation of medical images. Devices such as MRI machines, CT scanners, and ultrasound equipment rely on PCBs to function effectively, providing healthcare professionals with the detailed images needed for accurate diagnosis and treatment planning. The reliability and precision of PCBs are crucial in these applications, as any malfunction could lead to incorrect diagnoses or treatment delays. In pacemakers, PCBs are used to control the electrical impulses that regulate heartbeats, ensuring the device operates reliably and safely. The compact and durable nature of PCBs makes them ideal for use in these life-saving devices, where space is limited, and performance is critical. PCBs in pacemakers must meet stringent safety and reliability standards to ensure they function correctly over long periods, providing patients with the necessary support for their heart health. Electronic Health Records (EHRs) systems also benefit from the use of PCBs, as they enable the efficient processing and storage of patient data. PCBs in EHR systems support the integration of various electronic components, allowing for the seamless exchange of information between healthcare providers and improving the overall efficiency of patient care. In monitoring devices, PCBs are used to process and transmit data from sensors that track vital signs such as heart rate, blood pressure, and oxygen levels. These devices rely on PCBs to provide accurate and real-time data, enabling healthcare professionals to monitor patients' health and respond quickly to any changes. The use of PCBs in monitoring devices is essential for ensuring the reliability and accuracy of the data collected, which is critical for effective patient management. Other medical devices, such as infusion pumps, defibrillators, and surgical instruments, also rely on PCBs to function effectively. These devices require precise electronic control and reliable performance, which PCBs provide. The global market for Medical Device PCBs is driven by the increasing demand for these advanced technologies, as they enable the development of innovative medical devices that improve patient care and treatment outcomes. As the healthcare industry continues to evolve, the role of PCBs in medical devices will remain essential, supporting the creation of cutting-edge solutions that meet the needs of patients and healthcare providers worldwide.

Medical Device PCB - Global Market Outlook:

The outlook for the global market for Medical Device PCBs indicates a nuanced trajectory. In 2023, the market was valued at approximately US$ 26 million, reflecting its integral role in the medical device sector. However, forecasts suggest a slight contraction, with the market expected to adjust to a size of US$ 24 million by 2030, growing at a compound annual growth rate (CAGR) of 2.3% from 2024 to 2030. This adjustment reflects the dynamic nature of the market, influenced by various factors such as technological advancements, regulatory changes, and shifts in healthcare demands. Despite this contraction, the broader medical device market is poised for growth, estimated at US$ 603 billion in 2023 and projected to grow at a CAGR of 5% over the next six years. This growth is driven by the increasing demand for innovative healthcare solutions and the continuous advancement of medical technology. The role of Medical Device PCBs remains crucial in this context, as they support the development of advanced diagnostic and therapeutic equipment that enhances patient care and treatment outcomes. As the healthcare industry continues to evolve, the demand for reliable and sophisticated PCBs will persist, ensuring their continued relevance in the global market.

| Report Metric | Details |

| Report Name | Medical Device PCB - Market |

| Forecasted market size in 2030 | US$ 24 million |

| CAGR | 2.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | PCBgogo, Sierra Circuits, Epec Engineered Technologies, MCL, PCBCart, Twisted Traces, EMSG Inc., MOKO Technology, NCAB Group, PCB Connect, Valtronic, EBICS, PCBWay, Bittele Electronics, TTM Technologies, Pramura, Altek Electronics, Rayming, Printed Circuits LLC, VSE, SFI Circuits, GS Swiss PCB AG, Micro Systems Technologies Managemen |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |