What is Global Food Grade Anti-grease Conveyor Belt Market?

The Global Food Grade Anti-grease Conveyor Belt Market refers to the industry focused on the production and distribution of conveyor belts specifically designed for food processing environments. These belts are engineered to meet stringent hygiene standards and are resistant to grease and other contaminants commonly found in food production. They are crucial in ensuring that food products are transported efficiently and safely through various stages of processing, packaging, and distribution. The market encompasses a wide range of materials and technologies to cater to different types of food products and processing requirements. This includes belts made from plastic, metal, and other specialized materials that can withstand the rigorous demands of food production while maintaining compliance with food safety regulations. The global demand for these conveyor belts is driven by the increasing need for automation and efficiency in the food industry, as well as the growing emphasis on food safety and hygiene.

Plastic Conveyor Belt, Metal Conveyor Belt in the Global Food Grade Anti-grease Conveyor Belt Market:

Plastic conveyor belts and metal conveyor belts are two primary types of conveyor belts used in the Global Food Grade Anti-grease Conveyor Belt Market. Plastic conveyor belts are popular due to their lightweight, flexibility, and resistance to corrosion. They are often made from materials like polyethylene, polypropylene, and polyvinyl chloride (PVC), which are all FDA-approved for food contact. These belts are ideal for applications where hygiene is paramount, as they can be easily cleaned and sanitized. They are also resistant to oils and fats, making them suitable for transporting greasy food products. On the other hand, metal conveyor belts are known for their durability and strength. They are typically made from stainless steel, which is also resistant to corrosion and can withstand high temperatures. Metal belts are often used in applications where heavy loads need to be transported or where the conveyor belt will be exposed to extreme conditions, such as baking or frying processes. Both types of belts play a crucial role in the food industry, ensuring that food products are handled safely and efficiently. The choice between plastic and metal conveyor belts depends on the specific requirements of the food processing application, including the type of food being processed, the environmental conditions, and the need for hygiene and sanitation.

Food Processing, Distribution and Logistics in the Global Food Grade Anti-grease Conveyor Belt Market:

The usage of Global Food Grade Anti-grease Conveyor Belts is widespread in various areas such as food processing, distribution, and logistics. In food processing, these conveyor belts are essential for transporting raw materials, semi-finished products, and finished goods through different stages of production. They help in maintaining a continuous flow of materials, reducing manual handling, and minimizing the risk of contamination. The anti-grease properties of these belts ensure that they can handle greasy and oily food products without compromising on hygiene. In distribution, these conveyor belts are used in warehouses and distribution centers to move food products efficiently from one location to another. They help in streamlining the sorting, packing, and shipping processes, ensuring that food products reach their destinations in a timely and safe manner. In logistics, food grade anti-grease conveyor belts are used in various transportation systems, including trucks, ships, and planes, to ensure that food products are handled with care and remain uncontaminated during transit. The use of these belts in logistics helps in maintaining the quality and safety of food products, reducing the risk of spoilage and ensuring that they reach consumers in the best possible condition. Overall, the use of food grade anti-grease conveyor belts in food processing, distribution, and logistics is crucial for maintaining the safety, quality, and efficiency of the food supply chain.

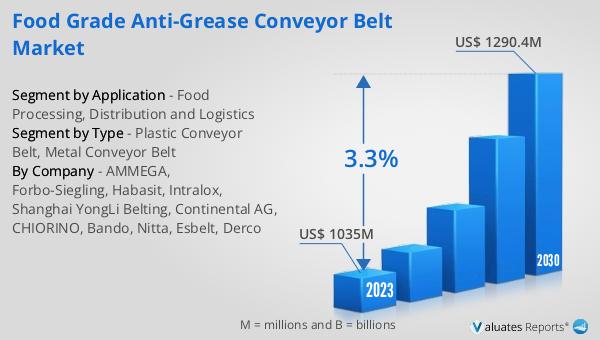

Global Food Grade Anti-grease Conveyor Belt Market Outlook:

The global Food Grade Anti-grease Conveyor Belt market was valued at US$ 1035 million in 2023 and is projected to grow to US$ 1290.4 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.3% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for high-quality, hygienic conveyor belts in the food industry. As food safety regulations become more stringent and the need for efficient food processing and distribution systems grows, the market for food grade anti-grease conveyor belts is expected to expand. These belts are essential for ensuring that food products are transported safely and efficiently through various stages of production and distribution, minimizing the risk of contamination and spoilage. The market's growth is also driven by advancements in conveyor belt technology, which have led to the development of more durable, efficient, and easy-to-clean belts that meet the specific needs of the food industry. As a result, the global Food Grade Anti-grease Conveyor Belt market is poised for steady growth in the coming years, driven by the increasing demand for safe and efficient food handling solutions.

| Report Metric | Details |

| Report Name | Food Grade Anti-grease Conveyor Belt Market |

| Accounted market size in 2023 | US$ 1035 million |

| Forecasted market size in 2030 | US$ 1290.4 million |

| CAGR | 3.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | AMMEGA, Forbo-Siegling, Habasit, Intralox, Shanghai YongLi Belting, Continental AG, CHIORINO, Bando, Nitta, Esbelt, Derco |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |