What is Global Commercial Floor Scrubbing Robot Market?

The Global Commercial Floor Scrubbing Robot Market refers to the industry focused on the development, production, and distribution of automated floor cleaning machines designed for commercial use. These robots are equipped with advanced technologies such as sensors, artificial intelligence, and machine learning to efficiently clean large floor areas in various commercial settings. They are designed to reduce the need for manual labor, enhance cleaning efficiency, and maintain high hygiene standards. The market encompasses a wide range of products, from small, compact robots suitable for tight spaces to larger, more robust machines capable of handling extensive floor areas. The increasing demand for automation in cleaning processes, driven by the need for cost-effective and efficient cleaning solutions, is a significant factor propelling the growth of this market. Additionally, the rising awareness about hygiene and cleanliness in commercial spaces, especially in the wake of the COVID-19 pandemic, has further accelerated the adoption of these robots. The market is characterized by continuous technological advancements, with manufacturers constantly innovating to improve the performance, efficiency, and user-friendliness of their products.

Less Than 55 cm, Between 55-80cm, More Than 80cm in the Global Commercial Floor Scrubbing Robot Market:

In the Global Commercial Floor Scrubbing Robot Market, the size of the robots plays a crucial role in determining their suitability for different applications. Robots with a width of less than 55 cm are typically designed for smaller, more confined spaces such as narrow hallways, small offices, and retail stores. These compact robots are highly maneuverable and can easily navigate tight corners and obstacles, making them ideal for environments where space is limited. On the other hand, robots with a width between 55-80 cm are more versatile and can be used in a variety of settings, including medium-sized commercial premises, educational institutions, and healthcare facilities. These robots strike a balance between maneuverability and cleaning efficiency, offering a good compromise for spaces that require thorough cleaning but are not excessively large. Finally, robots with a width of more than 80 cm are designed for large, open areas such as warehouses, airports, and large retail stores. These larger robots are equipped with powerful cleaning mechanisms and can cover extensive floor areas quickly and efficiently. They are particularly useful in environments where maintaining high standards of cleanliness is critical, and manual cleaning would be too time-consuming and labor-intensive. The choice of robot size depends on various factors, including the specific cleaning requirements, the layout of the space, and the budget available for cleaning equipment. Manufacturers in the Global Commercial Floor Scrubbing Robot Market offer a wide range of products to cater to these diverse needs, ensuring that there is a suitable solution for every application.

Commercial Premises, Industrial & Logistics, Airports, Others in the Global Commercial Floor Scrubbing Robot Market:

The usage of Global Commercial Floor Scrubbing Robots spans across various sectors, each with its unique requirements and challenges. In commercial premises such as shopping malls, office buildings, and hotels, these robots are employed to maintain cleanliness and hygiene standards. They are particularly useful in high-traffic areas where manual cleaning would be impractical and time-consuming. The robots can operate during off-peak hours, ensuring that the premises are clean and presentable for customers and employees. In industrial and logistics settings, floor scrubbing robots are used to keep large warehouse floors, production areas, and distribution centers clean. These environments often have stringent cleanliness standards to ensure the safety and efficiency of operations. The robots can handle tough cleaning tasks, such as removing industrial grime and spills, which would be challenging for manual cleaners. Airports are another significant area of application for commercial floor scrubbing robots. With thousands of passengers passing through daily, maintaining a clean and hygienic environment is crucial. The robots can efficiently clean large terminal areas, restrooms, and waiting lounges, ensuring a pleasant experience for travelers. Additionally, the robots can operate around the clock, minimizing disruptions to airport operations. Other areas where these robots are used include educational institutions, healthcare facilities, and public transportation hubs. In schools and universities, the robots help maintain clean and safe environments for students and staff. In healthcare facilities, they play a critical role in ensuring high hygiene standards to prevent the spread of infections. Public transportation hubs, such as train stations and bus terminals, also benefit from the efficiency and effectiveness of floor scrubbing robots. Overall, the versatility and efficiency of commercial floor scrubbing robots make them an invaluable asset in maintaining cleanliness and hygiene across various sectors.

Global Commercial Floor Scrubbing Robot Market Outlook:

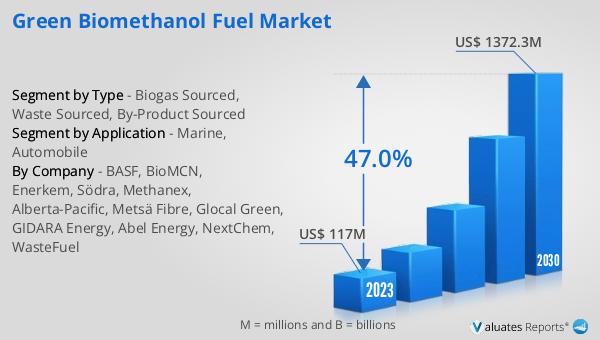

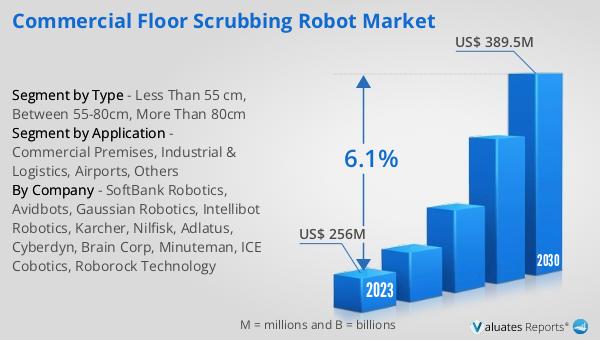

The global Commercial Floor Scrubbing Robot market was valued at US$ 256 million in 2023 and is anticipated to reach US$ 389.5 million by 2030, witnessing a CAGR of 6.1% during the forecast period 2024-2030. This market outlook highlights the significant growth potential of the industry, driven by the increasing demand for automated cleaning solutions in commercial settings. The rising awareness about hygiene and cleanliness, coupled with the need for cost-effective and efficient cleaning methods, is expected to propel the market's growth. The adoption of advanced technologies such as artificial intelligence and machine learning in these robots is also contributing to their growing popularity. As businesses and organizations continue to prioritize cleanliness and hygiene, the demand for commercial floor scrubbing robots is likely to increase, driving the market's expansion in the coming years.

| Report Metric | Details |

| Report Name | Commercial Floor Scrubbing Robot Market |

| Accounted market size in 2023 | US$ 256 million |

| Forecasted market size in 2030 | US$ 389.5 million |

| CAGR | 6.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

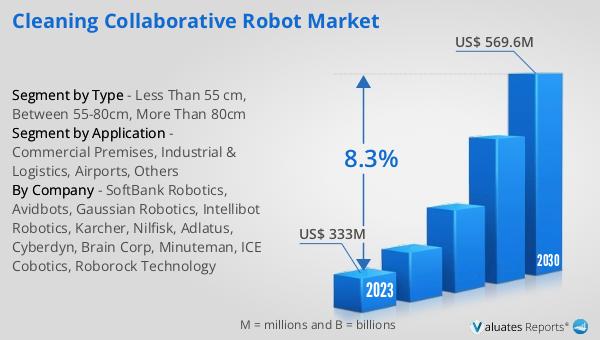

| By Company | SoftBank Robotics, Avidbots, Gaussian Robotics, Intellibot Robotics, Karcher, Nilfisk, Adlatus, Cyberdyn, Brain Corp, Minuteman, ICE Cobotics, Roborock Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |