What is Global Cross Roller Ring for Robot Market?

The Global Cross Roller Ring for Robot Market is a specialized segment within the broader robotics industry, focusing on the production and application of cross roller rings. These components are essential for the precise and smooth rotational movement of robotic joints and arms. Cross roller rings are designed with cylindrical rollers arranged perpendicularly, allowing them to handle loads from multiple directions, including radial, axial, and moment loads. This unique design makes them highly suitable for applications requiring high rigidity and accuracy. The market for these components is driven by the increasing adoption of robots in various industries, such as manufacturing, healthcare, and logistics. As automation becomes more prevalent, the demand for reliable and efficient robotic components like cross roller rings continues to grow. The market is characterized by continuous innovation and development, with manufacturers focusing on enhancing the performance and durability of these rings to meet the evolving needs of the robotics industry.

Straight-Type Inner Ring, Flange-Type Inner Ring in the Global Cross Roller Ring for Robot Market:

In the Global Cross Roller Ring for Robot Market, two primary types of inner rings are commonly used: Straight-Type Inner Ring and Flange-Type Inner Ring. The Straight-Type Inner Ring is designed for applications where space constraints are a significant consideration. This type of inner ring is straightforward in its design, offering a compact and efficient solution for various robotic applications. It is particularly suitable for robots that require high precision and smooth rotational movement in confined spaces. The simplicity of the Straight-Type Inner Ring also makes it easier to install and maintain, which is a crucial factor for industries looking to minimize downtime and enhance operational efficiency. On the other hand, the Flange-Type Inner Ring is designed to provide additional support and stability. This type of inner ring features a flange, which helps to distribute loads more evenly and reduce stress on the bearing. The Flange-Type Inner Ring is ideal for applications where the robot is subjected to heavy loads or where additional stability is required. This makes it a preferred choice for industrial robots used in heavy-duty applications such as welding, material handling, and assembly lines. Both types of inner rings play a crucial role in ensuring the smooth and efficient operation of robots, but their specific applications and benefits vary depending on the requirements of the task at hand. The choice between a Straight-Type Inner Ring and a Flange-Type Inner Ring depends on several factors, including the load capacity, space constraints, and the specific demands of the application. Manufacturers in the Global Cross Roller Ring for Robot Market continue to innovate and improve these components to meet the diverse needs of the robotics industry. By offering a range of options, they ensure that robots can operate with the highest levels of precision, efficiency, and reliability.

Service Robots, Industrial Robots in the Global Cross Roller Ring for Robot Market:

The Global Cross Roller Ring for Robot Market finds extensive usage in both service robots and industrial robots. Service robots, which are designed to assist humans in various tasks, benefit significantly from the precision and reliability offered by cross roller rings. These robots are used in a wide range of applications, including healthcare, hospitality, and domestic services. In healthcare, for instance, service robots equipped with cross roller rings can perform delicate tasks such as surgery or patient care with high accuracy and minimal error. The smooth rotational movement provided by these rings ensures that the robots can operate efficiently and safely in environments where precision is paramount. In the hospitality industry, service robots use cross roller rings to perform tasks such as serving food, cleaning, and providing customer service. The reliability and durability of these components ensure that the robots can operate continuously without frequent maintenance or downtime. Similarly, in domestic settings, service robots equipped with cross roller rings can perform tasks such as vacuuming, lawn mowing, and home security with high efficiency and reliability. On the other hand, industrial robots, which are used in manufacturing and production processes, also rely heavily on cross roller rings. These robots are often subjected to heavy loads and harsh operating conditions, making the durability and load-bearing capacity of cross roller rings crucial. In applications such as welding, material handling, and assembly lines, industrial robots equipped with cross roller rings can perform repetitive tasks with high precision and consistency. The ability of these rings to handle loads from multiple directions ensures that the robots can operate smoothly and efficiently, even in demanding environments. Additionally, the high rigidity and accuracy provided by cross roller rings enable industrial robots to perform complex tasks with minimal error, enhancing overall productivity and quality. The versatility and reliability of cross roller rings make them an essential component in both service and industrial robots, driving their widespread adoption in various industries.

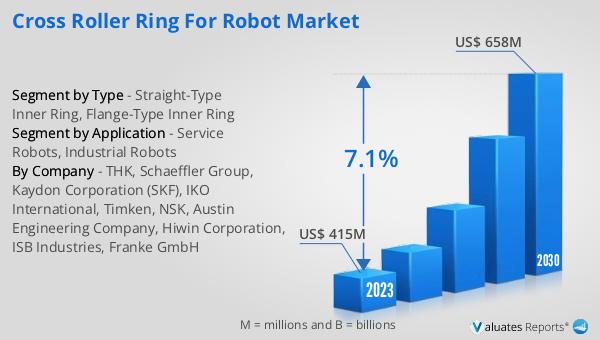

Global Cross Roller Ring for Robot Market Outlook:

The global Cross Roller Ring for Robot market was valued at US$ 415 million in 2023 and is anticipated to reach US$ 658 million by 2030, witnessing a CAGR of 7.1% during the forecast period from 2024 to 2030. This significant growth reflects the increasing demand for high-precision and reliable components in the robotics industry. As automation continues to advance across various sectors, the need for efficient and durable cross roller rings becomes more critical. These components play a vital role in ensuring the smooth and accurate operation of robotic systems, which is essential for enhancing productivity and reducing operational costs. The market's growth is also driven by continuous innovation and development, with manufacturers focusing on improving the performance and longevity of cross roller rings to meet the evolving needs of the industry. The rising adoption of robots in manufacturing, healthcare, logistics, and other sectors further fuels the demand for these components. As a result, the Global Cross Roller Ring for Robot Market is expected to experience robust growth in the coming years, driven by the increasing emphasis on automation and the need for high-quality robotic components.

| Report Metric | Details |

| Report Name | Cross Roller Ring for Robot Market |

| Accounted market size in 2023 | US$ 415 million |

| Forecasted market size in 2030 | US$ 658 million |

| CAGR | 7.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | THK, Schaeffler Group, Kaydon Corporation (SKF), IKO International, Timken, NSK, Austin Engineering Company, Hiwin Corporation, ISB Industries, Franke GmbH |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |