What is Global Bearings for Industrial Robot Market?

The Global Bearings for Industrial Robot Market refers to the worldwide industry focused on the production and distribution of bearings specifically designed for use in industrial robots. Bearings are crucial components in industrial robots as they facilitate smooth and precise movements, ensuring the robots can perform their tasks efficiently and accurately. These bearings are engineered to withstand the high loads and repetitive motions typical in robotic applications. The market encompasses various types of bearings, including constant section bearings, crossed roller bearings, and others, each offering unique advantages depending on the specific requirements of the robot and its application. As industrial automation continues to grow, driven by advancements in technology and increasing demand for efficiency in manufacturing processes, the global market for bearings in industrial robots is expected to expand significantly. This growth is fueled by the need for more sophisticated and reliable robotic systems in various industries, including automotive, electronics, and healthcare, among others.

Constant Section Bearing, Crossed Roller Bearing, Others in the Global Bearings for Industrial Robot Market:

Constant section bearings, crossed roller bearings, and other types of bearings play a pivotal role in the Global Bearings for Industrial Robot Market. Constant section bearings, also known as thin section bearings, are designed to provide high precision and reliability while maintaining a compact form factor. These bearings are ideal for applications where space is limited but high performance is required. They are commonly used in robotic arms and joints, where their ability to handle both radial and axial loads ensures smooth and accurate movements. Crossed roller bearings, on the other hand, are known for their ability to handle heavy loads and provide high rigidity. These bearings consist of cylindrical rollers arranged in a crisscross pattern, which allows them to support loads from multiple directions simultaneously. This makes them particularly suitable for applications requiring high precision and stability, such as in the joints and swivels of industrial robots. Other types of bearings used in industrial robots include angular contact ball bearings, which are designed to handle both radial and axial loads, and cylindrical roller bearings, which are known for their high load-carrying capacity and durability. Each type of bearing offers unique advantages, making them suitable for different aspects of robotic applications. For instance, angular contact ball bearings are often used in high-speed applications due to their ability to handle high rotational speeds, while cylindrical roller bearings are preferred in applications requiring high load capacity and durability. The choice of bearing type depends on various factors, including the specific requirements of the robot, the nature of the tasks it performs, and the operating environment. As the demand for industrial robots continues to grow, driven by the need for increased automation and efficiency in manufacturing processes, the market for these specialized bearings is expected to expand, offering new opportunities for innovation and development in the field of robotics.

Service Robots, Industrial Robots in the Global Bearings for Industrial Robot Market:

The usage of bearings in the Global Bearings for Industrial Robot Market extends to both service robots and industrial robots, each with distinct applications and requirements. Service robots, which are designed to assist humans in various tasks, rely heavily on bearings to ensure smooth and precise movements. These robots are used in a wide range of applications, including healthcare, hospitality, and domestic services. In healthcare, for instance, service robots equipped with high-precision bearings are used in surgical procedures, patient care, and rehabilitation, where accuracy and reliability are paramount. In the hospitality industry, service robots use bearings to perform tasks such as delivering food and beverages, cleaning, and providing customer service, all of which require smooth and efficient movements. In domestic settings, service robots, such as vacuum cleaners and lawn mowers, depend on bearings to navigate and perform their tasks effectively. On the other hand, industrial robots, which are used in manufacturing and production processes, also rely on bearings to ensure optimal performance. These robots are used in various industries, including automotive, electronics, and aerospace, where they perform tasks such as assembly, welding, painting, and material handling. Bearings in industrial robots are designed to withstand the high loads and repetitive motions typical in these applications, ensuring the robots can operate efficiently and accurately. For example, in the automotive industry, industrial robots equipped with high-load bearings are used in the assembly line to perform tasks such as welding and painting, where precision and reliability are crucial. In the electronics industry, industrial robots use high-precision bearings to handle delicate components and perform intricate assembly tasks. The choice of bearings in both service and industrial robots depends on the specific requirements of the application, including load capacity, precision, and durability. As the demand for automation continues to grow, driven by advancements in technology and the need for increased efficiency, the usage of bearings in both service and industrial robots is expected to expand, offering new opportunities for innovation and development in the field of robotics.

Global Bearings for Industrial Robot Market Outlook:

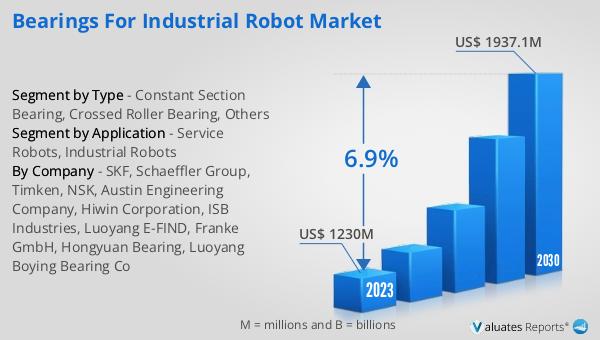

The global market for bearings used in industrial robots was valued at approximately $1.23 billion in 2023. Projections indicate that this market is set to grow significantly, reaching an estimated value of $1.937 billion by 2030. This growth is expected to occur at a compound annual growth rate (CAGR) of 6.9% over the forecast period from 2024 to 2030. This upward trend reflects the increasing demand for industrial robots across various sectors, driven by the need for enhanced automation and efficiency in manufacturing processes. The rising adoption of advanced technologies and the continuous development of more sophisticated and reliable robotic systems are key factors contributing to this market expansion. As industries such as automotive, electronics, and healthcare continue to integrate more robotic solutions into their operations, the demand for high-quality bearings that can ensure the smooth and precise functioning of these robots is expected to rise. This market growth also underscores the importance of innovation and development in the field of robotics, as manufacturers strive to meet the evolving needs of various industries.

| Report Metric | Details |

| Report Name | Bearings for Industrial Robot Market |

| Accounted market size in 2023 | US$ 1230 million |

| Forecasted market size in 2030 | US$ 1937.1 million |

| CAGR | 6.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SKF, Schaeffler Group, Timken, NSK, Austin Engineering Company, Hiwin Corporation, ISB Industries, Luoyang E-FIND, Franke GmbH, Hongyuan Bearing, Luoyang Boying Bearing Co |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |