What is Global Ultrafine Glass Fiber for AGM Separator Market?

The Global Ultrafine Glass Fiber for AGM Separator Market is a specialized segment within the broader glass fiber industry, focusing on the production and application of ultrafine glass fibers used in Absorbed Glass Mat (AGM) separators. These separators are crucial components in lead-acid batteries, which are widely used in various applications due to their reliability and efficiency. Ultrafine glass fibers are valued for their high surface area, excellent insulation properties, and ability to enhance the performance and longevity of AGM separators. The market for these fibers is driven by the increasing demand for energy storage solutions, particularly in automotive and industrial sectors. As industries continue to seek more efficient and sustainable energy solutions, the demand for high-performance AGM separators is expected to rise, thereby boosting the market for ultrafine glass fibers. The market is characterized by technological advancements, with manufacturers focusing on improving the quality and performance of glass fibers to meet the evolving needs of end-users. Additionally, the market is influenced by regulatory standards and environmental considerations, which drive innovation and the adoption of more sustainable production practices. Overall, the Global Ultrafine Glass Fiber for AGM Separator Market is poised for growth, driven by the increasing demand for efficient energy storage solutions across various industries.

Centrifugal Method, Flame Method in the Global Ultrafine Glass Fiber for AGM Separator Market:

The centrifugal method and flame method are two prominent techniques used in the production of ultrafine glass fibers for AGM separators. The centrifugal method involves the use of centrifugal force to transform molten glass into fine fibers. In this process, molten glass is poured into a rapidly spinning disc or rotor, which flings the glass outward through small orifices, forming fine fibers as it cools and solidifies. This method is known for its efficiency in producing uniform fibers with consistent diameters, which is crucial for the performance of AGM separators. The centrifugal method allows for precise control over the fiber diameter and length, making it a preferred choice for manufacturers aiming to produce high-quality ultrafine glass fibers. On the other hand, the flame method involves drawing fibers from molten glass using a flame. In this process, molten glass is fed through a nozzle and exposed to a high-temperature flame, which draws the glass into fine fibers. The flame method is known for its ability to produce extremely fine fibers, which are essential for applications requiring high surface area and insulation properties. However, this method can be more challenging to control compared to the centrifugal method, as it requires precise management of temperature and flow rates to achieve the desired fiber characteristics. Both methods have their advantages and limitations, and the choice between them often depends on the specific requirements of the application and the desired properties of the final product. Manufacturers may choose the centrifugal method for its efficiency and consistency, while the flame method may be preferred for applications requiring exceptionally fine fibers. The production of ultrafine glass fibers using these methods is a complex process that requires specialized equipment and expertise. Manufacturers must carefully control various parameters, such as temperature, flow rate, and spinning speed, to ensure the production of high-quality fibers that meet the stringent requirements of AGM separators. Additionally, advancements in technology and materials science continue to drive innovation in these production methods, enabling manufacturers to produce fibers with enhanced properties and performance. As the demand for high-performance AGM separators continues to grow, the development and optimization of production methods for ultrafine glass fibers will remain a key focus for manufacturers in the industry.

Automotive Start-Stop, Grid, UPS & Telecom, Others in the Global Ultrafine Glass Fiber for AGM Separator Market:

The usage of Global Ultrafine Glass Fiber for AGM Separator Market spans several critical areas, including automotive start-stop systems, grid energy storage, uninterruptible power supplies (UPS) and telecommunications, among others. In automotive start-stop systems, ultrafine glass fibers are used in AGM separators to enhance the performance and longevity of lead-acid batteries. These systems are designed to reduce fuel consumption and emissions by automatically shutting off the engine when the vehicle is stationary and restarting it when the driver releases the brake. The high surface area and excellent insulation properties of ultrafine glass fibers improve the efficiency and durability of AGM separators, making them ideal for the demanding conditions of automotive start-stop systems. In grid energy storage, ultrafine glass fibers play a crucial role in enhancing the performance of lead-acid batteries used for storing energy generated from renewable sources such as solar and wind. The ability of ultrafine glass fibers to improve the charge acceptance and cycle life of AGM separators makes them an attractive choice for grid energy storage applications, where reliability and efficiency are paramount. In the UPS and telecommunications sectors, ultrafine glass fibers are used in AGM separators to ensure the reliable operation of backup power systems. These systems provide critical power support during outages, ensuring the continuous operation of essential services and infrastructure. The high-performance characteristics of ultrafine glass fibers, such as their ability to withstand high temperatures and provide excellent insulation, make them ideal for use in AGM separators for UPS and telecommunications applications. Additionally, ultrafine glass fibers are used in various other applications, including industrial and commercial energy storage systems, where their superior performance characteristics contribute to the overall efficiency and reliability of the systems. The versatility and high performance of ultrafine glass fibers make them a valuable component in a wide range of energy storage applications, driving their demand across various industries. As the need for efficient and sustainable energy storage solutions continues to grow, the usage of ultrafine glass fibers in AGM separators is expected to expand, further solidifying their importance in the global market.

Global Ultrafine Glass Fiber for AGM Separator Market Outlook:

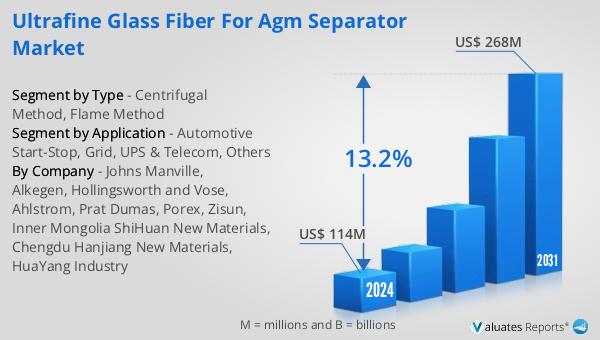

The global market for Ultrafine Glass Fiber used in AGM Separators is anticipated to expand significantly, with projections indicating growth from $114 million in 2024 to $268 million by 2031. This growth, at a compound annual growth rate (CAGR) of 13.2% from 2025 to 2031, is driven by key product segments and a variety of end-use applications. The increasing demand for efficient energy storage solutions across industries such as automotive, grid energy storage, and telecommunications is a major factor contributing to this growth. As industries continue to seek more sustainable and reliable energy solutions, the demand for high-performance AGM separators, and consequently ultrafine glass fibers, is expected to rise. However, the market is not without its challenges. Evolving U.S. tariff policies introduce trade-cost volatility and supply-chain uncertainty, which can impact the market dynamics. These policies may affect the cost of raw materials and finished products, influencing the pricing strategies of manufacturers and potentially affecting the overall market growth. Despite these challenges, the market for ultrafine glass fibers in AGM separators remains promising, driven by technological advancements and the increasing adoption of energy-efficient solutions across various industries. As manufacturers continue to innovate and optimize production methods, the market is poised for continued growth, offering significant opportunities for stakeholders in the industry.

| Report Metric | Details |

| Report Name | Ultrafine Glass Fiber for AGM Separator Market |

| Accounted market size in 2024 | US$ 114 million |

| Forecasted market size in 2031 | US$ 268 million |

| CAGR | 13.2% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Johns Manville, Alkegen, Hollingsworth and Vose, Ahlstrom, Prat Dumas, Porex, Zisun, Inner Mongolia ShiHuan New Materials, Chengdu Hanjiang New Materials, HuaYang Industry |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |