What is Global Plasma Transferred Arc Machine Market?

The Global Plasma Transferred Arc (PTA) Machine Market is a specialized segment within the broader welding and metalworking industry. PTA machines are advanced welding devices used to enhance the surface properties of metal components. They work by using a plasma arc to transfer a consumable powder or wire onto a substrate, creating a hard, wear-resistant surface. This process is particularly valuable in industries where components are subject to high wear and tear, such as aerospace, automotive, and oil and gas. The market for these machines is driven by the increasing demand for durable and high-performance components, as well as the need for cost-effective manufacturing solutions. As industries continue to seek ways to extend the life of their equipment and reduce maintenance costs, the demand for PTA machines is expected to grow. Additionally, advancements in technology are making these machines more efficient and versatile, further expanding their applications across various sectors. The global market is characterized by a mix of established players and emerging companies, all striving to innovate and capture a share of this growing market.

Desktop Type, Portable Type in the Global Plasma Transferred Arc Machine Market:

In the Global Plasma Transferred Arc Machine Market, there are two primary types of machines: Desktop Type and Portable Type. Desktop Type machines are typically larger and designed for stationary use in industrial settings. They are often used in manufacturing plants where high-volume production and precision are required. These machines are equipped with advanced features that allow for precise control over the welding process, making them ideal for applications that demand high accuracy and consistency. Desktop Type machines are commonly used in industries such as aerospace, automotive, and heavy machinery, where the quality and durability of components are critical. On the other hand, Portable Type machines are designed for flexibility and ease of use in various locations. They are smaller and more compact, making them suitable for on-site repairs and maintenance work. Portable Type machines are often used in industries such as construction, mining, and oil and gas, where equipment may need to be repaired or maintained in remote or challenging environments. These machines offer the advantage of mobility, allowing operators to perform welding tasks in locations that would be difficult to access with larger, stationary equipment. Despite their smaller size, Portable Type machines are capable of delivering high-quality welds and are equipped with features that ensure reliability and efficiency. Both Desktop and Portable Type machines play a crucial role in the Global Plasma Transferred Arc Machine Market, catering to the diverse needs of industries that require advanced welding solutions. As technology continues to evolve, these machines are becoming more sophisticated, offering enhanced capabilities and improved performance. This evolution is driving the adoption of PTA machines across various sectors, as companies seek to improve their manufacturing processes and extend the life of their equipment. The choice between Desktop and Portable Type machines often depends on the specific requirements of the application, including factors such as the size and complexity of the components being welded, the location of the work, and the desired level of precision and control. As the market continues to grow, manufacturers are focusing on developing machines that offer greater versatility and efficiency, enabling them to meet the changing needs of their customers.

Steel and Coal, Electricity and Cement, Petroleum, Machinery, Others in the Global Plasma Transferred Arc Machine Market:

The Global Plasma Transferred Arc Machine Market finds extensive usage across various industries, including Steel and Coal, Electricity and Cement, Petroleum, Machinery, and others. In the Steel and Coal industry, PTA machines are used to enhance the wear resistance of components such as rollers, crushers, and conveyor belts. These components are subject to high levels of abrasion and impact, and the application of a hard, wear-resistant surface can significantly extend their lifespan. In the Electricity and Cement industry, PTA machines are used to improve the durability of components such as turbine blades, cement kiln parts, and grinding rollers. These components operate under extreme conditions and require surfaces that can withstand high temperatures and corrosive environments. The application of PTA technology helps to reduce maintenance costs and downtime, improving the overall efficiency of operations. In the Petroleum industry, PTA machines are used to protect components such as drill bits, valves, and pumps from wear and corrosion. The harsh conditions of oil and gas extraction require equipment that can withstand high pressures and abrasive materials, and PTA technology provides a cost-effective solution for enhancing the performance and longevity of these components. In the Machinery industry, PTA machines are used to improve the wear resistance of components such as gears, shafts, and bearings. These components are critical to the operation of machinery and require surfaces that can withstand high levels of stress and friction. The application of PTA technology helps to reduce wear and tear, extending the life of the equipment and reducing the need for frequent repairs and replacements. Other industries that benefit from the use of PTA machines include aerospace, automotive, and marine, where the demand for high-performance components is driving the adoption of advanced welding technologies. As industries continue to seek ways to improve the efficiency and reliability of their operations, the demand for PTA machines is expected to grow, driving innovation and development in this specialized market.

Global Plasma Transferred Arc Machine Market Outlook:

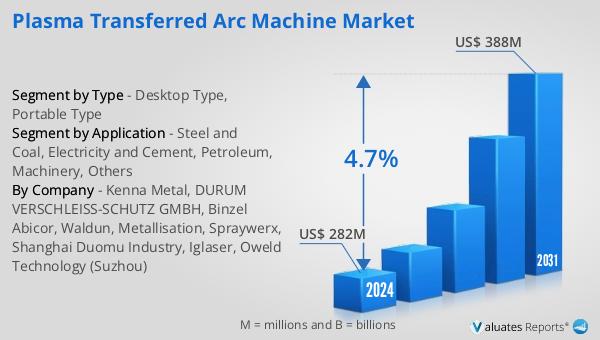

The outlook for the Global Plasma Transferred Arc Machine Market indicates a promising growth trajectory. The market is anticipated to expand from a valuation of US$ 282 million in 2024 to US$ 388 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.7% from 2025 to 2031. This growth is largely driven by the increasing demand for critical product segments and the diverse applications of PTA machines across various industries. As companies continue to seek cost-effective solutions for enhancing the durability and performance of their equipment, the adoption of PTA technology is expected to rise. However, the market is also facing challenges due to evolving U.S. tariff policies, which are introducing volatility in trade costs and creating uncertainty in supply chains. These factors are influencing the strategies of manufacturers and suppliers, as they navigate the complexities of international trade and seek to mitigate the impact of tariffs on their operations. Despite these challenges, the Global Plasma Transferred Arc Machine Market is poised for growth, as advancements in technology and increasing demand for high-performance components continue to drive innovation and development in this specialized field.

| Report Metric | Details |

| Report Name | Plasma Transferred Arc Machine Market |

| Accounted market size in 2024 | US$ 282 million |

| Forecasted market size in 2031 | US$ 388 million |

| CAGR | 4.7% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Kenna Metal, DURUM VERSCHLEISS-SCHUTZ GMBH, Binzel Abicor, Waldun, Metallisation, Spraywerx, Shanghai Duomu Industry, Iglaser, Oweld Technology (Suzhou) |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |