What is Global Wear-Resistant Ball Valves Market?

The Global Wear-Resistant Ball Valves Market is a specialized segment within the broader industrial valves industry, focusing on valves designed to withstand harsh conditions and abrasive materials. These valves are crucial in industries where the flow of abrasive or corrosive materials is common, such as mining, power generation, chemical processing, and water treatment. Wear-resistant ball valves are engineered to offer durability and longevity, reducing the need for frequent replacements and maintenance. They are typically made from high-strength materials like stainless steel, ceramic, or other alloys that can resist wear and tear over time. The market for these valves is driven by the increasing demand for efficient and reliable flow control solutions in various industrial applications. As industries continue to expand and modernize, the need for robust and long-lasting valve solutions becomes more pronounced, making wear-resistant ball valves an essential component in maintaining operational efficiency and safety. The market is characterized by a diverse range of products, catering to different sizes and specifications to meet the unique needs of various industries. This diversity ensures that there is a suitable solution for almost any application, further driving the market's growth and development.

Less than DN 100, DN 100-600, Above DN 600 in the Global Wear-Resistant Ball Valves Market:

In the Global Wear-Resistant Ball Valves Market, the classification based on size is crucial for understanding the specific applications and requirements of different industries. The size categories typically include Less than DN 100, DN 100-600, and Above DN 600. Valves that are Less than DN 100 are generally used in applications where precision and control are paramount. These smaller valves are often found in laboratory settings, small-scale chemical processing, and other environments where space is limited, and precise flow control is necessary. They are designed to handle lower flow rates and pressures, making them ideal for applications that require meticulous regulation of fluids or gases. On the other hand, valves in the DN 100-600 range are more versatile and are commonly used in medium to large-scale industrial applications. This size range is prevalent in industries such as power generation, where they are used to control the flow of steam, water, and other fluids essential for energy production. These valves must withstand higher pressures and flow rates, requiring robust construction and materials that can endure the demanding conditions of industrial environments. The DN 100-600 valves strike a balance between size and capability, offering a wide range of applications across various sectors. For applications requiring even larger flow capacities, valves Above DN 600 are utilized. These large valves are essential in industries like mining and water treatment, where they manage substantial volumes of abrasive or corrosive materials. In mining, for instance, these valves control the flow of slurry and other materials, ensuring efficient and safe operations. Similarly, in water treatment facilities, large valves are used to manage the flow of water and chemicals, playing a critical role in the purification and distribution processes. The construction of these valves must be exceptionally durable, as they are subjected to extreme conditions and high wear and tear. The ability to handle large volumes and pressures makes them indispensable in large-scale industrial operations. Each size category within the Global Wear-Resistant Ball Valves Market serves a distinct purpose, catering to the specific needs of various industries. The diversity in valve sizes ensures that there is a suitable solution for every application, from small-scale precision tasks to large-scale industrial operations. This segmentation allows manufacturers to tailor their products to meet the unique demands of different sectors, driving innovation and growth within the market. As industries continue to evolve and expand, the demand for specialized valve solutions will likely increase, further emphasizing the importance of size classification in the wear-resistant ball valves market.

Mining, Power, Chemicals, Water Treatment, Others in the Global Wear-Resistant Ball Valves Market:

The Global Wear-Resistant Ball Valves Market finds extensive usage across various industries, each with unique requirements and challenges. In the mining industry, these valves are indispensable due to their ability to handle abrasive materials like slurry, sand, and gravel. Mining operations involve the extraction and processing of minerals, which requires robust and durable equipment to ensure efficiency and safety. Wear-resistant ball valves are designed to withstand the harsh conditions of mining environments, reducing downtime and maintenance costs. They play a crucial role in controlling the flow of materials, ensuring smooth and uninterrupted operations. In the power generation sector, wear-resistant ball valves are essential for managing the flow of steam, water, and other fluids used in energy production. Power plants operate under high-pressure conditions, requiring valves that can endure extreme temperatures and pressures. These valves help maintain the efficiency and safety of power generation processes by providing reliable flow control solutions. In chemical processing, wear-resistant ball valves are used to handle corrosive and abrasive chemicals, ensuring safe and efficient operations. The chemical industry demands valves that can resist chemical attacks and maintain integrity under harsh conditions. Wear-resistant ball valves are designed to meet these requirements, providing reliable performance and reducing the risk of leaks or failures. In water treatment facilities, these valves are used to manage the flow of water and chemicals, playing a critical role in purification and distribution processes. Water treatment involves the removal of contaminants and impurities, requiring precise control of flow rates and pressures. Wear-resistant ball valves ensure the efficient operation of water treatment systems, contributing to the delivery of clean and safe water. Other industries, such as oil and gas, pharmaceuticals, and food and beverage, also rely on wear-resistant ball valves for their durability and reliability. These valves are used in various applications, from controlling the flow of oil and gas to managing the processing of pharmaceuticals and food products. The versatility and robustness of wear-resistant ball valves make them an essential component in a wide range of industrial applications, ensuring efficiency, safety, and reliability across different sectors.

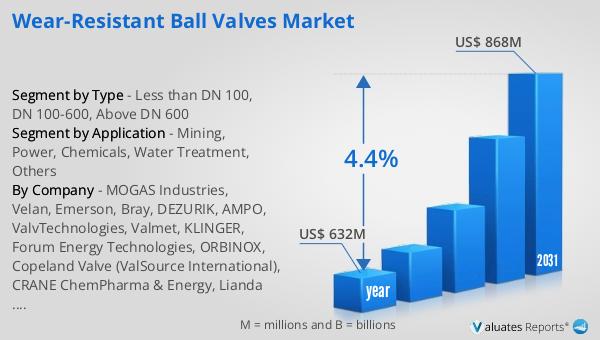

Global Wear-Resistant Ball Valves Market Outlook:

The outlook for the Global Wear-Resistant Ball Valves Market indicates a promising growth trajectory. In 2024, the market was valued at approximately $632 million. By 2031, it is anticipated to expand to a revised size of $868 million, reflecting a compound annual growth rate (CAGR) of 4.4% over the forecast period. This growth is driven by the increasing demand for durable and reliable valve solutions across various industries. As industries continue to modernize and expand, the need for wear-resistant ball valves becomes more pronounced, contributing to the market's steady growth. The market's expansion is also supported by advancements in materials and manufacturing technologies, which enhance the performance and longevity of wear-resistant ball valves. These innovations enable manufacturers to develop valves that can withstand even the most challenging conditions, further driving demand. Additionally, the growing focus on operational efficiency and safety in industrial processes fuels the adoption of wear-resistant ball valves, as they offer reliable flow control solutions that minimize downtime and maintenance costs. The market's positive outlook reflects the increasing importance of wear-resistant ball valves in ensuring the smooth and efficient operation of various industrial processes, making them a critical component in the global industrial landscape.

| Report Metric | Details |

| Report Name | Wear-Resistant Ball Valves Market |

| Accounted market size in year | US$ 632 million |

| Forecasted market size in 2031 | US$ 868 million |

| CAGR | 4.4% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | MOGAS Industries, Velan, Emerson, Bray, DEZURIK, AMPO, ValvTechnologies, Valmet, KLINGER, Forum Energy Technologies, ORBINOX, Copeland Valve (ValSource International), CRANE ChemPharma & Energy, Lianda Valve, Yuanda Valve, Shanghai Nuwave Valve, Guogong Holding Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |