What is Global Agate Grinding Machine Market?

The Global Agate Grinding Machine Market is a specialized segment within the broader machinery industry, focusing on the production and distribution of machines designed to grind agate stones. Agate is a type of quartz known for its hardness and vibrant colors, making it a popular choice for decorative items, jewelry, and industrial applications. The grinding machines used in this market are engineered to handle the unique properties of agate, ensuring precision and efficiency in shaping and polishing the stones. These machines are utilized in various sectors, including jewelry manufacturing, scientific research, and industrial applications, where the precise grinding of agate is required. The market is characterized by a range of machine types, from small-scale units for artisanal use to large, industrial-grade machines for mass production. As demand for agate products continues to grow, driven by both aesthetic and functional applications, the market for agate grinding machines is expected to expand, offering opportunities for innovation and technological advancement. The market's growth is also influenced by factors such as advancements in grinding technology, increasing demand for high-quality agate products, and the expansion of end-use industries.

Ball Mill, Vibration, Planet in the Global Agate Grinding Machine Market:

In the Global Agate Grinding Machine Market, several types of grinding machines are utilized, each serving distinct purposes and offering unique advantages. Among these, the Ball Mill, Vibration Mill, and Planetary Mill are prominent. The Ball Mill is a cylindrical device used in grinding or mixing materials like ores, chemicals, ceramic raw materials, and paints. It operates on the principle of impact and attrition, where the grinding media, typically steel balls, are used to reduce the size of the material. The Ball Mill is highly efficient for grinding agate due to its ability to handle large volumes and produce fine particles, making it ideal for industrial applications where precision and consistency are crucial. On the other hand, the Vibration Mill is designed to grind materials through the application of vibrational energy. This type of mill is particularly effective for grinding brittle materials like agate, as the vibrations cause the grinding media to impact the material with high energy, resulting in rapid size reduction. The Vibration Mill is favored for its ability to produce ultra-fine particles and its relatively low energy consumption compared to other grinding methods. Lastly, the Planetary Mill is a type of grinding machine that uses a combination of rotational and translational motion to achieve fine grinding. In this mill, the grinding jars rotate on their own axes while simultaneously revolving around a central axis, creating a complex motion that enhances the grinding process. The Planetary Mill is highly effective for grinding agate due to its ability to produce extremely fine particles and its versatility in handling various materials. It is widely used in laboratories and research institutions where precise control over particle size is required. Each of these grinding machines plays a vital role in the Global Agate Grinding Machine Market, catering to different needs and applications. The choice of machine depends on factors such as the desired particle size, production volume, and specific material properties. As the market continues to evolve, advancements in grinding technology are expected to enhance the efficiency and capabilities of these machines, further driving their adoption across various industries.

Metallurgy, Building Materials, Chemical Industry, Others in the Global Agate Grinding Machine Market:

The Global Agate Grinding Machine Market finds extensive usage across several key industries, including metallurgy, building materials, the chemical industry, and others. In the field of metallurgy, agate grinding machines are employed to prepare samples for analysis and testing. The precise grinding capabilities of these machines ensure that metallurgical samples are of consistent quality, which is crucial for accurate testing and analysis. This is particularly important in quality control processes, where the properties of metals and alloys need to be thoroughly examined. In the building materials industry, agate grinding machines are used to process materials such as cement, ceramics, and glass. The machines' ability to produce fine particles is essential for creating high-quality building materials that meet industry standards. The grinding process also enhances the reactivity of materials, improving their performance in construction applications. In the chemical industry, agate grinding machines are utilized to grind and mix chemical compounds, facilitating the production of various chemical products. The machines' precision and efficiency ensure that chemical reactions occur uniformly, resulting in high-quality end products. This is particularly important in the production of pharmaceuticals, where the consistency and purity of chemical compounds are critical. Beyond these industries, agate grinding machines are also used in other sectors such as electronics, where they are employed to grind materials for semiconductor manufacturing. The machines' ability to produce ultra-fine particles is essential for creating the high-purity materials required in electronic components. Additionally, agate grinding machines are used in research and development, where they facilitate the preparation of samples for scientific studies. The versatility and precision of agate grinding machines make them indispensable tools across a wide range of industries, driving their demand and contributing to the growth of the Global Agate Grinding Machine Market.

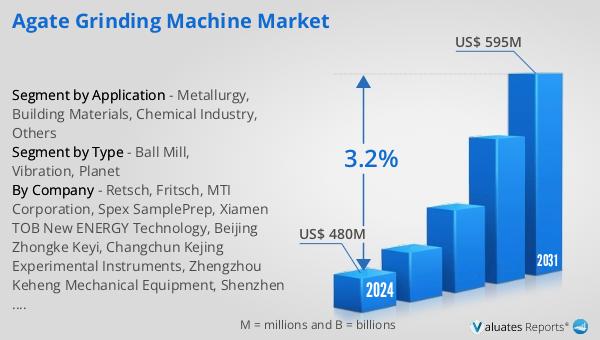

Global Agate Grinding Machine Market Outlook:

The outlook for the Global Agate Grinding Machine Market indicates a promising growth trajectory, with the market expected to expand from $480 million in 2024 to $595 million by 2031. This growth, at a compound annual growth rate (CAGR) of 3.2% from 2025 to 2031, is driven by the increasing demand for agate grinding machines across various product segments and end-use applications. The market's expansion is fueled by the rising need for precision grinding in industries such as metallurgy, building materials, and chemicals, where the quality and consistency of materials are paramount. However, the market also faces challenges, particularly in the form of evolving U.S. tariff policies, which introduce volatility in trade costs and create uncertainty in supply chains. These factors can impact the pricing and availability of agate grinding machines, affecting market dynamics. Despite these challenges, the market is poised for growth, supported by technological advancements in grinding machinery and the increasing adoption of agate grinding machines in emerging markets. As industries continue to prioritize quality and efficiency, the demand for advanced grinding solutions is expected to rise, driving the market forward. The Global Agate Grinding Machine Market's outlook remains positive, with opportunities for innovation and expansion in the coming years.

| Report Metric | Details |

| Report Name | Agate Grinding Machine Market |

| Accounted market size in 2024 | US$ 480 million |

| Forecasted market size in 2031 | US$ 595 million |

| CAGR | 3.2% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Retsch, Fritsch, MTI Corporation, Spex SamplePrep, Xiamen TOB New ENERGY Technology, Beijing Zhongke Keyi, Changchun Kejing Experimental Instruments, Zhengzhou Keheng Mechanical Equipment, Shenzhen Kejing Zhida Technology, Beijing Mingchen Zhonghuan Technology, Changsha Tianchuang Powder Technology, Shanghai Jiubin Instruments |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |