What is Global Rotary Table Blast Machine Market?

The Global Rotary Table Blast Machine Market refers to the industry focused on the production and sale of rotary table blast machines, which are specialized equipment used for surface cleaning and finishing. These machines are designed to remove rust, scale, and other surface contaminants from metal parts, making them essential in industries where surface preparation is critical. The market encompasses various types of rotary table blast machines, each tailored to specific applications and industries. The demand for these machines is driven by their efficiency and effectiveness in cleaning and preparing surfaces, which is crucial for ensuring the quality and longevity of metal products. As industries such as automotive, aerospace, and shipbuilding continue to grow, the need for reliable and efficient surface preparation solutions like rotary table blast machines is expected to increase. This market is characterized by technological advancements aimed at improving the performance and efficiency of these machines, as well as expanding their applications across different sectors. Companies operating in this market are focused on innovation and developing machines that meet the evolving needs of their customers, ensuring they remain competitive in a dynamic and growing industry.

Single-table, Multi-table in the Global Rotary Table Blast Machine Market:

In the Global Rotary Table Blast Machine Market, machines are generally categorized into single-table and multi-table configurations, each serving distinct purposes and offering unique advantages. Single-table rotary blast machines are designed with a single rotating table where parts are placed for blasting. These machines are typically used for smaller production runs or when dealing with larger, heavier parts that require more focused attention. The single-table design allows for precise control over the blasting process, ensuring that each part receives the necessary treatment. This configuration is particularly beneficial in industries where customization and precision are paramount, such as aerospace and automotive, where parts often have complex geometries and require meticulous surface preparation. On the other hand, multi-table rotary blast machines feature multiple rotating tables, allowing for simultaneous processing of several parts. This design significantly enhances productivity and efficiency, making it ideal for high-volume production environments. Industries such as shipbuilding and heavy machinery manufacturing, where large quantities of parts need to be processed quickly, benefit greatly from the multi-table configuration. The ability to process multiple parts at once reduces downtime and increases throughput, which is crucial for meeting tight production schedules. Additionally, multi-table machines often come with advanced automation features, further streamlining the blasting process and reducing the need for manual intervention. Both single-table and multi-table rotary blast machines are integral to the Global Rotary Table Blast Machine Market, catering to the diverse needs of various industries. Manufacturers in this market are continually innovating to enhance the capabilities of these machines, focusing on improving efficiency, reducing energy consumption, and expanding the range of materials that can be processed. As industries continue to evolve and demand more sophisticated surface preparation solutions, the role of single-table and multi-table rotary blast machines will remain vital in ensuring the quality and performance of metal products across the globe.

Automotive, Aerospace, Shipbuilding, Others in the Global Rotary Table Blast Machine Market:

The Global Rotary Table Blast Machine Market finds extensive applications across various industries, including automotive, aerospace, shipbuilding, and others, due to its ability to efficiently clean and prepare metal surfaces. In the automotive industry, rotary table blast machines are used to remove rust, scale, and other contaminants from car parts, ensuring they are ready for painting or coating. This process is crucial for enhancing the durability and appearance of vehicles, as well as ensuring the proper adhesion of coatings. The precision and efficiency of rotary table blast machines make them ideal for handling the complex geometries of automotive components, contributing to the overall quality and performance of vehicles. In the aerospace sector, the demand for rotary table blast machines is driven by the need for meticulous surface preparation of aircraft components. These machines are used to clean and prepare parts such as turbine blades, landing gear, and structural components, which require high levels of precision and consistency. The aerospace industry places a strong emphasis on safety and reliability, making the use of advanced surface preparation technologies like rotary table blast machines essential. In shipbuilding, rotary table blast machines play a critical role in preparing large metal surfaces for painting and coating. The harsh marine environment demands robust and durable coatings, and proper surface preparation is key to achieving this. Rotary table blast machines are used to clean and prepare ship hulls, decks, and other components, ensuring they are free from rust and contaminants before coating. This process not only enhances the longevity of ships but also contributes to their overall performance and safety. Beyond these industries, rotary table blast machines are also used in various other sectors, including heavy machinery manufacturing, construction, and metal fabrication. Their versatility and efficiency make them suitable for a wide range of applications, from cleaning and preparing metal parts to enhancing the surface finish of finished products. As industries continue to seek ways to improve the quality and performance of their products, the demand for advanced surface preparation solutions like rotary table blast machines is expected to grow.

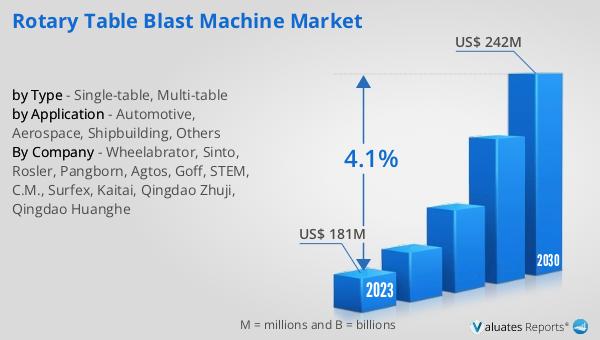

Global Rotary Table Blast Machine Market Outlook:

The outlook for the Global Rotary Table Blast Machine Market indicates a promising growth trajectory, with the market expected to expand from $190 million in 2024 to $251 million by 2031. This growth, at a compound annual growth rate (CAGR) of 4.1% from 2025 to 2031, is driven by the increasing demand for rotary table blast machines across various industries and their critical role in surface preparation. The market's expansion is fueled by the diverse applications of these machines, which are essential for ensuring the quality and durability of metal products in sectors such as automotive, aerospace, and shipbuilding. As industries continue to prioritize efficiency and precision in their manufacturing processes, the need for advanced surface preparation technologies like rotary table blast machines is expected to rise. However, the market also faces challenges, particularly in the form of evolving U.S. tariff policies, which introduce trade-cost volatility and supply-chain uncertainty. These factors could impact the cost and availability of raw materials and components, potentially affecting the production and pricing of rotary table blast machines. Despite these challenges, the market is poised for growth, driven by technological advancements and the increasing adoption of automation in surface preparation processes. Companies operating in this market are focused on innovation and developing machines that meet the evolving needs of their customers, ensuring they remain competitive in a dynamic and growing industry.

| Report Metric | Details |

| Report Name | Rotary Table Blast Machine Market |

| Accounted market size in 2024 | US$ 190 million |

| Forecasted market size in 2031 | US$ 251 million |

| CAGR | 4.1% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Wheelabrator, Sinto, Rosler, Pangborn, Agtos, Goff, STEM, C.M., Surfex, Kaitai, Qingdao Zhuji, Qingdao Huanghe |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |