What is Global Automobile Wheel Hub Forging Hydraulic Press Market?

The Global Automobile Wheel Hub Forging Hydraulic Press Market is a specialized segment within the broader automotive manufacturing industry, focusing on the production of wheel hubs through the process of forging using hydraulic presses. This market is integral to the automotive sector as wheel hubs are crucial components that connect the wheels to the vehicle, ensuring stability and safety. The hydraulic press used in this process applies a significant amount of pressure to shape metal into the desired form, enhancing the strength and durability of the wheel hubs. This market is driven by the increasing demand for vehicles worldwide, advancements in manufacturing technologies, and the need for high-performance and reliable automotive components. As the automotive industry continues to evolve with trends like electric vehicles and autonomous driving, the demand for advanced wheel hub forging technologies is expected to grow. The market is characterized by a mix of established players and new entrants, each striving to innovate and improve the efficiency and effectiveness of their forging processes. This competitive landscape encourages continuous improvement and adaptation to meet the changing needs of the automotive industry.

Hot Die Forging Hydraulic Press, Cold Forging Hydraulic Press in the Global Automobile Wheel Hub Forging Hydraulic Press Market:

Hot Die Forging Hydraulic Press and Cold Forging Hydraulic Press are two critical technologies within the Global Automobile Wheel Hub Forging Hydraulic Press Market, each offering distinct advantages and applications. Hot die forging involves heating the metal to a high temperature before it is shaped, which makes the metal more malleable and easier to form into complex shapes. This process is particularly beneficial for producing large and intricate wheel hubs that require precise dimensions and superior mechanical properties. The high temperature allows for better flow of the metal, reducing the risk of defects and improving the overall quality of the final product. On the other hand, cold forging is performed at or near room temperature, which results in a different set of benefits. Cold forging is known for producing parts with excellent surface finish and dimensional accuracy, as the metal is not subjected to the thermal expansion and contraction that occurs in hot forging. This process is ideal for smaller wheel hubs or those that require tight tolerances and high strength. Both hot die forging and cold forging hydraulic presses are essential in meeting the diverse needs of the automotive industry, providing manufacturers with the flexibility to choose the most appropriate method based on the specific requirements of the wheel hub being produced. The choice between hot and cold forging depends on various factors, including the size and complexity of the wheel hub, the desired mechanical properties, and the production volume. Manufacturers must carefully consider these factors to optimize their production processes and ensure the highest quality of their products. As the automotive industry continues to advance, the demand for both hot die forging and cold forging hydraulic presses is expected to grow, driven by the need for high-performance and reliable wheel hubs. This growth is further supported by technological advancements in forging equipment, which are enabling manufacturers to achieve greater precision, efficiency, and cost-effectiveness in their operations. The ongoing development of new materials and forging techniques is also contributing to the evolution of this market, providing manufacturers with new opportunities to enhance the performance and durability of their wheel hubs. In conclusion, hot die forging and cold forging hydraulic presses are indispensable tools in the Global Automobile Wheel Hub Forging Hydraulic Press Market, each offering unique benefits that cater to the diverse needs of the automotive industry. By leveraging these technologies, manufacturers can produce high-quality wheel hubs that meet the stringent demands of modern vehicles, ensuring safety, reliability, and performance on the road.

Passenger Vehicle, Commercial Vehicle in the Global Automobile Wheel Hub Forging Hydraulic Press Market:

The Global Automobile Wheel Hub Forging Hydraulic Press Market plays a crucial role in the production of wheel hubs for both passenger vehicles and commercial vehicles, each with its own set of requirements and challenges. In the passenger vehicle segment, the focus is on producing wheel hubs that offer a balance of performance, comfort, and safety. Passenger vehicles, which include cars, SUVs, and minivans, require wheel hubs that are lightweight yet strong, to enhance fuel efficiency and handling. The use of advanced forging techniques, such as hot die forging and cold forging, allows manufacturers to produce wheel hubs that meet these criteria, providing the necessary strength and durability without adding unnecessary weight. Additionally, the aesthetic appeal of passenger vehicles is an important consideration, and the precision offered by forging hydraulic presses ensures that the wheel hubs have a high-quality finish that complements the overall design of the vehicle. In the commercial vehicle segment, which includes trucks, buses, and other heavy-duty vehicles, the requirements for wheel hubs are different. These vehicles are designed to carry heavy loads and operate in demanding conditions, so the wheel hubs must be exceptionally strong and durable. The use of hot die forging is particularly beneficial in this segment, as it allows for the production of large and robust wheel hubs that can withstand the stresses of heavy-duty applications. The ability to produce wheel hubs with precise dimensions and superior mechanical properties is crucial for ensuring the safety and reliability of commercial vehicles, which often operate over long distances and in challenging environments. The Global Automobile Wheel Hub Forging Hydraulic Press Market is essential in meeting the diverse needs of both passenger and commercial vehicles, providing manufacturers with the tools and technologies needed to produce high-quality wheel hubs that meet the specific requirements of each segment. As the automotive industry continues to evolve, the demand for advanced wheel hub forging technologies is expected to grow, driven by the need for high-performance and reliable components that can meet the stringent demands of modern vehicles. The ongoing development of new materials and forging techniques is also contributing to the evolution of this market, providing manufacturers with new opportunities to enhance the performance and durability of their wheel hubs. In conclusion, the Global Automobile Wheel Hub Forging Hydraulic Press Market is a vital component of the automotive industry, supporting the production of wheel hubs for both passenger and commercial vehicles. By leveraging advanced forging technologies, manufacturers can produce high-quality wheel hubs that meet the diverse needs of the automotive industry, ensuring safety, reliability, and performance on the road.

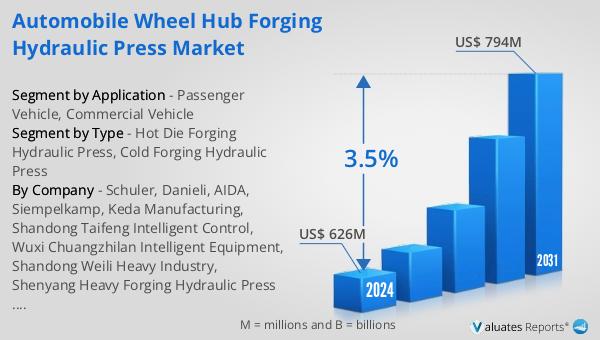

Global Automobile Wheel Hub Forging Hydraulic Press Market Outlook:

The outlook for the Global Automobile Wheel Hub Forging Hydraulic Press Market indicates a promising growth trajectory, with the market expected to expand from $626 million in 2024 to $794 million by 2031. This growth, at a compound annual growth rate (CAGR) of 3.5% from 2025 to 2031, is driven by the increasing demand for critical product segments and a wide range of end-use applications. As the automotive industry continues to evolve, the need for high-performance and reliable wheel hubs is becoming more pronounced, fueling the demand for advanced forging technologies. However, the market is also facing challenges, particularly in the form of evolving U.S. tariff policies, which are introducing trade cost volatility and supply chain uncertainty. These factors are creating a complex and dynamic environment for manufacturers, who must navigate these challenges while continuing to innovate and improve their production processes. Despite these challenges, the Global Automobile Wheel Hub Forging Hydraulic Press Market is poised for growth, driven by the ongoing demand for high-quality wheel hubs and the continuous development of new materials and forging techniques. As manufacturers adapt to the changing landscape, they are likely to find new opportunities to enhance the performance and durability of their products, ensuring their continued success in the market.

| Report Metric | Details |

| Report Name | Automobile Wheel Hub Forging Hydraulic Press Market |

| Accounted market size in 2024 | US$ 626 million |

| Forecasted market size in 2031 | US$ 794 million |

| CAGR | 3.5% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Schuler, Danieli, AIDA, Siempelkamp, Keda Manufacturing, Shandong Taifeng Intelligent Control, Wuxi Chuangzhilan Intelligent Equipment, Shandong Weili Heavy Industry, Shenyang Heavy Forging Hydraulic Press Manufacturing, Hefei Forging Intelligent Manufacturing, Chengdu Zhengxi Intelligent Equipment |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |