What is Global Diamond Single Crystal Processing Machine Market?

The Global Diamond Single Crystal Processing Machine Market is a specialized segment within the broader machinery industry, focusing on the processing of diamond single crystals. These machines are essential for cutting, shaping, and polishing diamond crystals, which are used in various high-tech applications due to their exceptional hardness and thermal conductivity. The market encompasses a range of machines designed to handle the unique properties of diamonds, ensuring precision and efficiency in processing. The demand for these machines is driven by industries such as electronics, optics, and semiconductors, where diamond components are increasingly used for their superior performance characteristics. As technology advances, the need for high-quality diamond processing machines continues to grow, with manufacturers investing in research and development to enhance machine capabilities and meet the evolving needs of end-users. The market is characterized by a mix of established players and emerging companies, each striving to offer innovative solutions that cater to the specific requirements of their clients. Overall, the Global Diamond Single Crystal Processing Machine Market plays a crucial role in supporting the production of advanced materials and components that are integral to modern technology.

Laser Processing Machine, Mechanical Processing Machine, Chemical Processing Machine in the Global Diamond Single Crystal Processing Machine Market:

In the Global Diamond Single Crystal Processing Machine Market, three primary types of machines are utilized: Laser Processing Machines, Mechanical Processing Machines, and Chemical Processing Machines. Each of these machines serves a distinct purpose in the processing of diamond single crystals, leveraging different technologies to achieve precise and efficient results. Laser Processing Machines use high-intensity laser beams to cut and shape diamond crystals with exceptional precision. These machines are favored for their ability to produce intricate designs and patterns without causing damage to the diamond's structure. The laser technology allows for non-contact processing, minimizing the risk of contamination and ensuring a high-quality finish. Laser Processing Machines are particularly useful in applications where precision and detail are paramount, such as in the production of microelectronics and intricate optical components. Mechanical Processing Machines, on the other hand, rely on physical tools and abrasives to cut, grind, and polish diamond crystals. These machines are known for their robustness and ability to handle large volumes of material, making them ideal for bulk processing tasks. Mechanical Processing Machines are often used in industries where speed and efficiency are critical, such as in the production of industrial-grade diamonds for cutting and drilling applications. Despite their reliance on physical contact, advancements in mechanical processing technology have led to the development of machines that offer improved precision and reduced wear on tools. Chemical Processing Machines utilize chemical reactions to alter the surface properties of diamond crystals. These machines are employed in processes such as chemical vapor deposition (CVD), where thin diamond films are grown on substrates for use in electronic and optical devices. Chemical Processing Machines are valued for their ability to produce high-purity diamond films with controlled thickness and composition. The use of chemical processing techniques allows for the creation of diamond materials with tailored properties, enhancing their performance in specific applications. In summary, each type of processing machine in the Global Diamond Single Crystal Processing Machine Market offers unique advantages, catering to the diverse needs of industries that rely on diamond materials. As technology continues to evolve, these machines are expected to become even more sophisticated, enabling the production of diamond components with unprecedented precision and quality.

Semiconductor Industry, Optical Industry, Other in the Global Diamond Single Crystal Processing Machine Market:

The Global Diamond Single Crystal Processing Machine Market finds extensive usage across various industries, including the semiconductor industry, optical industry, and others. In the semiconductor industry, diamond single crystals are highly valued for their exceptional thermal conductivity and electrical insulating properties. These characteristics make them ideal for use in high-power electronic devices, where efficient heat dissipation is crucial to maintaining performance and reliability. Diamond single crystals are used as heat spreaders and substrates in semiconductor devices, helping to enhance their efficiency and longevity. The precision offered by diamond processing machines ensures that these components meet the stringent quality standards required in the semiconductor industry. In the optical industry, diamond single crystals are used to manufacture lenses, windows, and other optical components that require high transparency and durability. The hardness and scratch resistance of diamond make it an excellent material for optical applications, where clarity and longevity are essential. Diamond processing machines enable the production of optical components with precise dimensions and smooth surfaces, ensuring optimal performance in demanding environments. The ability to produce complex shapes and patterns with laser processing machines further expands the possibilities for innovative optical designs. Beyond the semiconductor and optical industries, diamond single crystal processing machines are also used in other sectors such as aerospace, automotive, and medical devices. In the aerospace industry, diamond components are used in high-performance sensors and instruments, where their durability and thermal stability are critical. In the automotive industry, diamond-coated tools and components are employed to enhance the performance and lifespan of engines and other mechanical systems. In the medical field, diamond-tipped surgical instruments and implants benefit from the biocompatibility and wear resistance of diamond materials. The versatility of diamond single crystals and the precision offered by processing machines make them indispensable in a wide range of applications, driving the growth of the Global Diamond Single Crystal Processing Machine Market. As industries continue to seek advanced materials that offer superior performance, the demand for diamond processing machines is expected to rise, supporting innovation and development across multiple sectors.

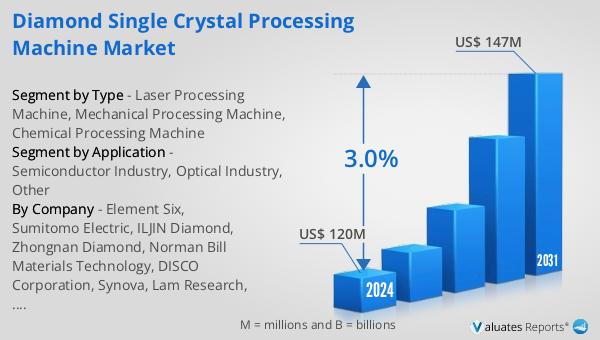

Global Diamond Single Crystal Processing Machine Market Outlook:

The outlook for the Global Diamond Single Crystal Processing Machine Market indicates a steady growth trajectory, with the market expected to expand from US$ 120 million in 2024 to US$ 147 million by 2031. This growth, at a compound annual growth rate (CAGR) of 3.0% from 2025 to 2031, is driven by the increasing demand for diamond processing machines across various critical product segments and diverse end-use applications. The market's expansion is fueled by the need for high-precision and high-quality diamond components in industries such as electronics, optics, and semiconductors. As these industries continue to evolve and innovate, the demand for advanced processing machines that can deliver superior performance and efficiency is expected to rise. However, the market also faces challenges, particularly in the form of evolving U.S. tariff policies, which introduce trade-cost volatility and supply-chain uncertainty. These factors can impact the cost and availability of raw materials and components, affecting the overall market dynamics. Despite these challenges, the Global Diamond Single Crystal Processing Machine Market is poised for growth, driven by technological advancements and the increasing adoption of diamond materials in high-tech applications. Manufacturers are likely to focus on developing innovative solutions that address the specific needs of their clients, ensuring that they remain competitive in a rapidly changing market landscape.

| Report Metric | Details |

| Report Name | Diamond Single Crystal Processing Machine Market |

| Accounted market size in 2024 | US$ 120 million |

| Forecasted market size in 2031 | US$ 147 million |

| CAGR | 3.0% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Element Six, Sumitomo Electric, ILJIN Diamond, Zhongnan Diamond, Norman Bill Materials Technology, DISCO Corporation, Synova, Lam Research, Okamoto Machine Tool Works, AM Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |