What is Global Lens Surface Defect Inspection Instrument Market?

The Global Lens Surface Defect Inspection Instrument Market is a specialized segment within the broader optical inspection industry, focusing on the detection and analysis of surface defects on lenses. These instruments are crucial for ensuring the quality and performance of lenses used in various applications, from consumer electronics to high-precision optical devices. The market is driven by the increasing demand for high-quality lenses, which are essential in industries such as photography, medical devices, and aerospace. As technology advances, the need for precise and reliable inspection tools becomes more critical, pushing manufacturers to innovate and improve their offerings. The market is characterized by a mix of established players and new entrants, each striving to offer more accurate, efficient, and user-friendly inspection solutions. With the growing emphasis on quality control and the rising complexity of lens designs, the Global Lens Surface Defect Inspection Instrument Market is poised for steady growth, driven by technological advancements and expanding applications across various sectors. The market's evolution is also influenced by regulatory standards and the increasing adoption of automation in manufacturing processes, which necessitate advanced inspection capabilities.

Semi-Automatic, Full-Automatic in the Global Lens Surface Defect Inspection Instrument Market:

In the Global Lens Surface Defect Inspection Instrument Market, the distinction between semi-automatic and full-automatic systems is significant, as each offers unique advantages and caters to different operational needs. Semi-automatic inspection systems require some level of human intervention, typically in the setup or initial stages of the inspection process. These systems are often favored by smaller manufacturers or those with limited production volumes, as they offer a balance between cost and functionality. Operators can adjust settings and parameters to suit specific inspection requirements, providing a level of flexibility that is beneficial in environments where lens specifications frequently change. Semi-automatic systems are generally more affordable than their fully automatic counterparts, making them an attractive option for companies looking to enhance their inspection capabilities without a substantial financial outlay. On the other hand, full-automatic inspection systems are designed to operate with minimal human intervention, offering a high degree of precision and efficiency. These systems are ideal for large-scale manufacturing operations where consistency and speed are paramount. Full-automatic systems utilize advanced technologies such as machine vision, artificial intelligence, and robotics to perform comprehensive inspections, identifying even the smallest defects with high accuracy. The integration of these technologies allows for real-time data analysis and feedback, enabling manufacturers to make immediate adjustments to their production processes. This level of automation not only improves product quality but also reduces the likelihood of human error, leading to increased operational efficiency. While full-automatic systems require a higher initial investment, the long-term benefits in terms of productivity and quality assurance often justify the cost. As the demand for high-quality lenses continues to rise, manufacturers are increasingly adopting full-automatic systems to meet stringent quality standards and enhance their competitive edge. The choice between semi-automatic and full-automatic systems ultimately depends on a company's specific needs, production volume, and budget. However, as technology continues to evolve, the line between these two types of systems is becoming increasingly blurred, with many manufacturers offering hybrid solutions that combine the best features of both. This trend reflects the growing demand for flexible and scalable inspection solutions that can adapt to the changing needs of the lens manufacturing industry.

Glasses Manufacturing, Photography, Medical, Aerospace, Others in the Global Lens Surface Defect Inspection Instrument Market:

The Global Lens Surface Defect Inspection Instrument Market plays a crucial role in various industries, including glasses manufacturing, photography, medical, aerospace, and others. In glasses manufacturing, these instruments are essential for ensuring the quality and durability of lenses used in eyewear. By detecting surface defects such as scratches, pits, or inclusions, manufacturers can ensure that their products meet the required standards for optical clarity and performance. This is particularly important in the production of prescription lenses, where even minor defects can significantly impact the user's vision. In the photography industry, high-quality lenses are critical for capturing sharp and detailed images. Inspection instruments help manufacturers maintain the precision and quality of camera lenses, ensuring that photographers can rely on their equipment to deliver the best possible results. The medical field also relies heavily on lens inspection instruments, particularly in the production of medical imaging devices and surgical equipment. High-quality lenses are essential for accurate diagnostics and successful surgical outcomes, making defect inspection a vital part of the manufacturing process. In the aerospace industry, lenses are used in a variety of applications, from navigation systems to surveillance equipment. The harsh conditions and high-stakes nature of aerospace operations demand lenses that are free from defects and capable of withstanding extreme environments. Inspection instruments help ensure that these lenses meet the rigorous standards required for aerospace applications. Beyond these specific industries, lens surface defect inspection instruments are also used in other sectors where optical components play a critical role. This includes industries such as telecommunications, where lenses are used in fiber optic systems, and the automotive industry, where lenses are integral to advanced driver-assistance systems (ADAS). In each of these areas, the ability to detect and address surface defects is crucial for maintaining product quality and performance. As the demand for high-quality optical components continues to grow, the Global Lens Surface Defect Inspection Instrument Market is expected to expand, driven by the need for precise and reliable inspection solutions across a wide range of applications.

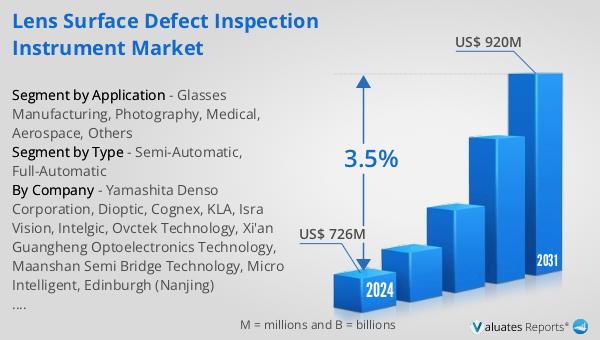

Global Lens Surface Defect Inspection Instrument Market Outlook:

The outlook for the Global Lens Surface Defect Inspection Instrument Market indicates a promising growth trajectory, with the market expected to expand from $726 million in 2024 to $920 million by 2031. This growth, at a compound annual growth rate (CAGR) of 3.5% from 2025 to 2031, is fueled by the increasing demand for high-quality lenses across various industries and the critical role these instruments play in ensuring product quality. The market's expansion is supported by the diverse range of end-use applications, from consumer electronics to aerospace, each requiring precise and reliable inspection solutions. However, the evolving U.S. tariff policies introduce an element of uncertainty, potentially affecting trade costs and supply chain dynamics. These policies could lead to increased volatility in the market, as manufacturers navigate the complexities of international trade and adjust their strategies to mitigate potential risks. Despite these challenges, the market's growth prospects remain strong, driven by technological advancements and the continuous push for higher quality standards in lens manufacturing. As companies invest in more advanced inspection technologies, the market is likely to see further innovation and development, enhancing the capabilities of inspection instruments and expanding their applications across various sectors.

| Report Metric | Details |

| Report Name | Lens Surface Defect Inspection Instrument Market |

| Accounted market size in 2024 | US$ 726 million |

| Forecasted market size in 2031 | US$ 920 million |

| CAGR | 3.5% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Yamashita Denso Corporation, Dioptic, Cognex, KLA, Isra Vision, Intelgic, Ovctek Technology, Xi'an Guangheng Optoelectronics Technology, Maanshan Semi Bridge Technology, Micro Intelligent, Edinburgh (Nanjing) Optoelectronic Equipment, Hefei Zhichang Photoelectric Technology, Nanjing Wavelength Photoelectric Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |