What is Global Battery Solvent Recovery Technology Market?

The Global Battery Solvent Recovery Technology Market is an emerging sector focused on the recovery and recycling of solvents used in battery manufacturing and disposal. As the demand for batteries, particularly lithium-ion batteries, continues to rise due to the proliferation of electric vehicles and renewable energy storage solutions, the need for efficient and sustainable solvent recovery processes becomes increasingly critical. Solvents play a vital role in the production of batteries, serving as carriers for active materials and facilitating the formation of the battery's internal structure. However, the production and disposal of these solvents can have significant environmental impacts if not managed properly. The market for solvent recovery technology aims to address these challenges by developing systems and processes that can effectively reclaim and purify used solvents, thereby reducing waste and minimizing environmental harm. This market is driven by technological advancements, regulatory pressures for sustainable practices, and the growing awareness of the environmental footprint of battery production. Companies operating in this space are investing in research and development to enhance the efficiency and cost-effectiveness of solvent recovery technologies, making them an integral part of the global push towards more sustainable industrial practices.

Recovery Rate>95%, Recovery Rate>99% in the Global Battery Solvent Recovery Technology Market:

In the Global Battery Solvent Recovery Technology Market, the recovery rates of solvents are crucial indicators of the efficiency and effectiveness of the recovery processes. Recovery Rate>95% and Recovery Rate>99% are two benchmarks that signify the percentage of solvent that can be successfully reclaimed from used materials. A recovery rate greater than 95% indicates that a substantial portion of the solvent is being recovered, which is essential for reducing waste and minimizing the environmental impact of battery production. This level of recovery is often achieved through advanced filtration and distillation techniques that separate the solvent from impurities and contaminants. On the other hand, a recovery rate greater than 99% represents an even higher standard of efficiency, where nearly all of the solvent is reclaimed and can be reused in the production process. Achieving such a high recovery rate requires cutting-edge technology and precise control over the recovery process, often involving multiple stages of purification and refinement. The benefits of achieving high recovery rates are manifold. Firstly, it significantly reduces the need for fresh solvent production, thereby conserving natural resources and reducing the carbon footprint associated with solvent manufacturing. Secondly, it lowers the cost of production for battery manufacturers, as reclaimed solvents are typically less expensive than new ones. Thirdly, it aligns with regulatory requirements and industry standards for environmental sustainability, which are becoming increasingly stringent across the globe. Companies that can achieve high recovery rates are often seen as leaders in sustainability and innovation, gaining a competitive edge in the market. However, reaching these high recovery rates is not without its challenges. It requires substantial investment in technology and infrastructure, as well as ongoing research and development to optimize the recovery processes. Additionally, the quality of the recovered solvent must be carefully monitored to ensure it meets the necessary standards for reuse in battery production. Despite these challenges, the pursuit of high recovery rates is a key focus for many companies in the Global Battery Solvent Recovery Technology Market, as it offers significant economic and environmental benefits. As the market continues to grow, driven by the increasing demand for batteries and the push for sustainable practices, the importance of achieving high recovery rates will only become more pronounced. Companies that can successfully navigate the complexities of solvent recovery and achieve these high benchmarks will be well-positioned to capitalize on the opportunities presented by this burgeoning market.

Chemicals, Electronics, Others in the Global Battery Solvent Recovery Technology Market:

The Global Battery Solvent Recovery Technology Market finds its applications across various sectors, including chemicals, electronics, and others, each with unique requirements and benefits. In the chemicals sector, solvent recovery technology is crucial for minimizing waste and reducing the environmental impact of chemical manufacturing processes. Solvents are widely used in the production of various chemicals, and their recovery and reuse can significantly lower production costs and resource consumption. By implementing advanced recovery technologies, chemical manufacturers can enhance their sustainability credentials and comply with increasingly stringent environmental regulations. In the electronics sector, the demand for efficient solvent recovery is driven by the need to manage the environmental impact of electronic waste and the production of electronic components. Solvents are used in the manufacturing of semiconductors, printed circuit boards, and other electronic components, and their recovery is essential for reducing the environmental footprint of these processes. By reclaiming and reusing solvents, electronics manufacturers can reduce their reliance on new solvent production, lower their operational costs, and improve their sustainability performance. Additionally, solvent recovery technology can help electronics companies meet regulatory requirements and industry standards for environmental protection, which are becoming increasingly important in the global market. Beyond chemicals and electronics, the Global Battery Solvent Recovery Technology Market also finds applications in other industries, such as automotive, pharmaceuticals, and textiles. In the automotive industry, the recovery of solvents used in the production of batteries and other components can help manufacturers reduce waste and improve their environmental performance. In the pharmaceutical industry, solvent recovery is essential for minimizing waste and reducing the environmental impact of drug manufacturing processes. Similarly, in the textiles industry, solvent recovery can help manufacturers reduce their environmental footprint and comply with environmental regulations. Overall, the Global Battery Solvent Recovery Technology Market plays a critical role in promoting sustainability and reducing the environmental impact of various industries. By enabling the efficient recovery and reuse of solvents, this market helps companies lower their production costs, conserve natural resources, and meet regulatory requirements for environmental protection. As the demand for sustainable practices continues to grow, the importance of solvent recovery technology will only increase, making it an essential component of the global push towards more sustainable industrial practices.

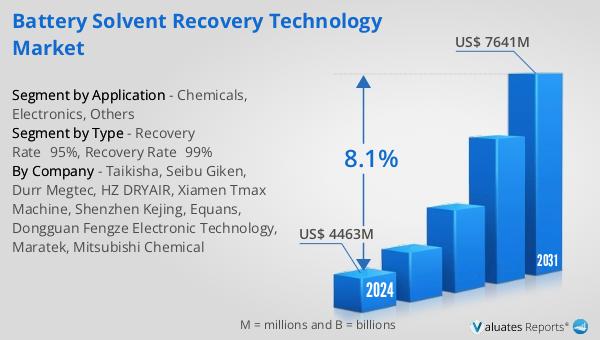

Global Battery Solvent Recovery Technology Market Outlook:

The outlook for the Global Battery Solvent Recovery Technology Market indicates a promising growth trajectory, with the market expected to expand from US$ 4,463 million in 2024 to US$ 7,641 million by 2031. This growth, at a compound annual growth rate (CAGR) of 8.1% from 2025 to 2031, is driven by the increasing demand for efficient and sustainable solvent recovery solutions across various industries. The market's expansion is fueled by critical product segments and diverse end-use applications, which highlight the versatility and importance of solvent recovery technology in today's industrial landscape. As industries continue to prioritize sustainability and environmental responsibility, the demand for advanced solvent recovery solutions is expected to rise, driving further innovation and investment in this market. Companies operating in the Global Battery Solvent Recovery Technology Market are likely to benefit from this growth by developing and offering cutting-edge solutions that meet the evolving needs of their customers. By focusing on enhancing the efficiency and cost-effectiveness of their recovery processes, these companies can capitalize on the growing demand for sustainable practices and gain a competitive edge in the market. Overall, the outlook for the Global Battery Solvent Recovery Technology Market is positive, with significant opportunities for growth and innovation in the coming years.

| Report Metric | Details |

| Report Name | Battery Solvent Recovery Technology Market |

| Accounted market size in 2024 | US$ 4463 million |

| Forecasted market size in 2031 | US$ 7641 million |

| CAGR | 8.1% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Sales by Region |

|

| By Company | Taikisha, Seibu Giken, Durr Megtec, HZ DRYAIR, Xiamen Tmax Machine, Shenzhen Kejing, Equans, Dongguan Fengze Electronic Technology, Maratek, Mitsubishi Chemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |