What is Global Two-Chuck Laser Tube Cutter Market?

The Global Two-Chuck Laser Tube Cutter Market is a specialized segment within the broader laser cutting industry, focusing on machines designed to cut tubes and pipes with precision and efficiency. These machines are equipped with two chucks, which are devices used to hold the tube or pipe in place during the cutting process. This dual-chuck system allows for greater stability and accuracy, making it ideal for industries that require precise cuts and intricate designs. The market for these machines is driven by the increasing demand for high-quality, efficient, and precise cutting solutions across various industries such as automotive, construction, and manufacturing. The technology behind two-chuck laser tube cutters enables them to handle a wide range of materials, including metals and plastics, making them versatile tools in industrial applications. As industries continue to seek ways to improve production efficiency and product quality, the demand for advanced cutting solutions like two-chuck laser tube cutters is expected to grow. This market is characterized by continuous technological advancements, with manufacturers focusing on enhancing the capabilities of these machines to meet the evolving needs of their customers.

Maximum Processing Weight <200kg, Maximum Processing Weight 1000-2000kg, Maximum Processing Weight >500kg in the Global Two-Chuck Laser Tube Cutter Market:

In the Global Two-Chuck Laser Tube Cutter Market, machines are categorized based on their maximum processing weight, which indicates the heaviest load they can handle during operation. The category of Maximum Processing Weight <200kg is designed for lighter applications, often used in industries where precision and speed are more critical than handling heavy materials. These machines are typically employed in sectors like electronics or small-scale manufacturing, where the materials being cut are lighter and require intricate detailing. They offer high precision and are often more compact, making them suitable for smaller workshops or production lines with limited space. On the other hand, machines with a Maximum Processing Weight of 1000-2000kg are built for heavy-duty applications. These are used in industries such as construction and shipbuilding, where large and heavy tubes or pipes need to be cut with precision. The robust construction of these machines allows them to handle the stress and strain of cutting thick and heavy materials, ensuring durability and reliability in demanding environments. These machines often come with advanced features like automated loading and unloading systems to enhance productivity and reduce manual labor. Meanwhile, the category of Maximum Processing Weight >500kg serves as a middle ground, offering a balance between handling capacity and precision. These machines are versatile and can be used in a variety of industries, including automotive and aerospace, where both precision and the ability to handle moderately heavy materials are required. They are often equipped with advanced software and control systems that allow for complex cutting patterns and designs, catering to industries that require high customization and flexibility. The choice of machine based on maximum processing weight depends largely on the specific needs of the industry and the materials being processed. Each category offers unique advantages, and manufacturers often provide customization options to tailor the machines to specific industrial requirements. As the demand for efficient and precise cutting solutions continues to rise, the Global Two-Chuck Laser Tube Cutter Market is expected to see innovations and advancements that further enhance the capabilities and applications of these machines.

Petroleum Pipeline, Construction Machinery, Automotive Manufacturing, Household Appliances, Fitness Equipment, Others in the Global Two-Chuck Laser Tube Cutter Market:

The Global Two-Chuck Laser Tube Cutter Market finds extensive usage across various industries due to its ability to deliver precise and efficient cutting solutions. In the petroleum pipeline industry, these machines are crucial for cutting pipes to exact specifications, ensuring a perfect fit and reducing the risk of leaks or failures. The precision offered by two-chuck laser tube cutters is essential in this industry, where even minor deviations can lead to significant issues. In construction machinery, these cutters are used to fabricate components that require high precision and durability. The ability to cut complex shapes and designs with accuracy makes these machines invaluable in the production of construction equipment and machinery parts. Automotive manufacturing is another area where the Global Two-Chuck Laser Tube Cutter Market plays a vital role. The automotive industry demands high precision and efficiency in the production of components, and these machines deliver just that. They are used to cut various parts, including exhaust systems, chassis components, and other structural elements, ensuring that each piece meets the stringent quality standards of the industry. In the household appliances sector, two-chuck laser tube cutters are used to produce components for appliances such as refrigerators, washing machines, and ovens. The precision and efficiency of these machines ensure that each component fits perfectly, contributing to the overall quality and performance of the appliance. Fitness equipment manufacturers also benefit from the capabilities of two-chuck laser tube cutters. These machines are used to cut and shape components for equipment such as treadmills, exercise bikes, and weight machines. The precision and versatility of these cutters allow manufacturers to create equipment that is both functional and aesthetically pleasing. Beyond these industries, the Global Two-Chuck Laser Tube Cutter Market also serves other sectors that require precise and efficient cutting solutions. The versatility and advanced technology of these machines make them suitable for a wide range of applications, from small-scale manufacturing to large industrial operations. As industries continue to evolve and demand more efficient and precise production methods, the usage of two-chuck laser tube cutters is expected to expand, driving further growth in this market.

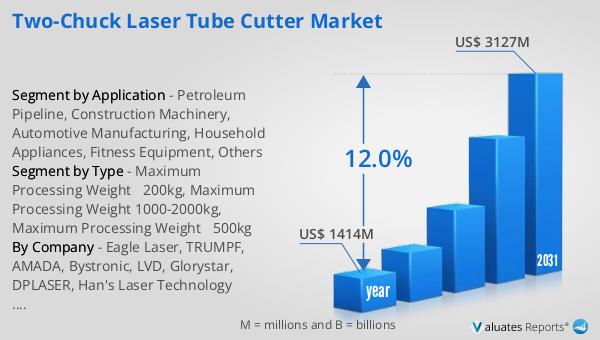

Global Two-Chuck Laser Tube Cutter Market Outlook:

The global market for Two-Chuck Laser Tube Cutters was valued at approximately $1,414 million in 2024. This market is anticipated to experience significant growth, with projections indicating that it will reach an estimated size of $3,127 million by the year 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 12.0% over the forecast period. The increasing demand for precision cutting solutions across various industries is a key driver of this market expansion. Industries such as automotive, construction, and manufacturing are continuously seeking advanced technologies that can enhance production efficiency and product quality. Two-chuck laser tube cutters, with their ability to deliver precise and efficient cutting, are well-positioned to meet these demands. The market's growth is also supported by ongoing technological advancements, which are enhancing the capabilities and applications of these machines. As manufacturers continue to innovate and improve their offerings, the Global Two-Chuck Laser Tube Cutter Market is expected to see sustained growth and development. This positive market outlook reflects the increasing importance of precision cutting solutions in modern industrial applications and the growing adoption of advanced technologies across various sectors.

| Report Metric | Details |

| Report Name | Two-Chuck Laser Tube Cutter Market |

| Accounted market size in year | US$ 1414 million |

| Forecasted market size in 2031 | US$ 3127 million |

| CAGR | 12.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Eagle Laser, TRUMPF, AMADA, Bystronic, LVD, Glorystar, DPLASER, Han's Laser Technology Industry Group Co., Ltd, Dongguan Glorystar Laser Technology Co., Ltd., Jinan Jinqiang Laser CNC Equipment Co., Ltd., Xuzhou Ruima Intelligent Technology Co., Ltd., Jinan Xintian Technology Co., Ltd., Shenzhen Dade Laser Technology Co., Ltd., Jinan Bodor CNC Machine Co., Ltd., Pentium Laser (Wenzhou) Co., Ltd., SuZhou Quick Laser Technology Co., Ltd., Jinan Senfeng Technology Co., Ltd., Songgu Laser Technology (Jiangsu) Co., Ltd., Aore Laser, OREE LASER, HGTECH, HSG Laser, JIATAILASER, Krrass, Longxin Laser |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |