What is Global Cell to Chassis Technology Market?

The Global Cell to Chassis Technology Market represents a transformative shift in the automotive industry, focusing on the integration of battery cells directly into the vehicle chassis. This innovative approach eliminates the traditional battery pack, allowing for a more streamlined and efficient design. By embedding the battery cells into the chassis, manufacturers can reduce the overall weight of the vehicle, enhance structural integrity, and improve energy efficiency. This technology is particularly significant as the demand for electric vehicles (EVs) continues to rise, driven by environmental concerns and the push for sustainable transportation solutions. The integration of cell to chassis technology not only optimizes space within the vehicle but also contributes to a lower center of gravity, enhancing vehicle stability and performance. As automakers strive to meet stringent emissions regulations and consumer expectations for longer driving ranges, the adoption of cell to chassis technology is poised to play a crucial role in the evolution of electric mobility.

Battery Pack Chassis Integration, Battery Cell Chassis Integration in the Global Cell to Chassis Technology Market:

Battery Pack Chassis Integration and Battery Cell Chassis Integration are two pivotal components of the Global Cell to Chassis Technology Market, each offering unique advantages and challenges. Battery Pack Chassis Integration involves incorporating the entire battery pack into the vehicle's chassis. This method allows for a more modular approach, where the battery pack can be easily replaced or upgraded without significant alterations to the vehicle's structure. It provides flexibility in design and manufacturing, enabling automakers to adapt to different vehicle models and consumer needs. However, this approach may result in a heavier vehicle due to the additional casing and support structures required to house the battery pack. On the other hand, Battery Cell Chassis Integration takes a more radical approach by embedding individual battery cells directly into the chassis. This method eliminates the need for a separate battery pack, reducing weight and maximizing space efficiency. By integrating cells into the chassis, manufacturers can achieve a more compact and streamlined design, which can lead to improved aerodynamics and energy efficiency. This approach also enhances the structural integrity of the vehicle, as the chassis itself becomes a critical component of the battery system. However, the integration of cells into the chassis presents challenges in terms of thermal management and maintenance. Ensuring that the cells remain cool and operate efficiently requires advanced cooling systems and materials. Additionally, maintenance and repair can be more complex, as accessing individual cells may require disassembling parts of the chassis. Despite these challenges, the benefits of Battery Cell Chassis Integration are significant, particularly in terms of weight reduction and energy efficiency. As the automotive industry continues to innovate and push the boundaries of electric vehicle design, both Battery Pack Chassis Integration and Battery Cell Chassis Integration will play crucial roles in shaping the future of transportation. Automakers must carefully consider the trade-offs between these two approaches, balancing factors such as cost, performance, and consumer preferences to determine the best path forward. Ultimately, the choice between Battery Pack Chassis Integration and Battery Cell Chassis Integration will depend on a variety of factors, including the specific requirements of the vehicle, the target market, and the overall goals of the manufacturer. As technology advances and new materials and techniques become available, the potential for further innovation in cell to chassis technology is vast, promising exciting developments in the years to come.

Passenger Car, Commercial Car in the Global Cell to Chassis Technology Market:

The usage of Global Cell to Chassis Technology Market in passenger cars and commercial vehicles highlights the versatility and potential of this innovative approach. In passenger cars, cell to chassis technology offers several advantages that align with consumer demands for efficiency, performance, and sustainability. By integrating battery cells directly into the chassis, automakers can reduce the weight of the vehicle, leading to improved energy efficiency and longer driving ranges. This is particularly important for electric passenger cars, where range anxiety remains a significant concern for consumers. The streamlined design also allows for more interior space, enhancing comfort and convenience for passengers. Additionally, the lower center of gravity achieved through cell to chassis integration improves handling and stability, providing a more enjoyable driving experience. In commercial vehicles, the benefits of cell to chassis technology are equally compelling. Commercial vehicles, such as trucks and buses, require robust and reliable power systems to support heavy loads and long-distance travel. By embedding battery cells into the chassis, manufacturers can optimize the weight distribution and structural integrity of the vehicle, enhancing performance and durability. This is particularly important for electric commercial vehicles, which must balance the need for high power output with the demands of efficiency and sustainability. The integration of cells into the chassis also allows for greater flexibility in vehicle design, enabling manufacturers to tailor solutions to specific applications and customer needs. For example, delivery trucks can benefit from increased cargo space and reduced weight, while buses can achieve improved passenger capacity and comfort. Furthermore, the adoption of cell to chassis technology in commercial vehicles supports the broader goals of reducing emissions and promoting sustainable transportation solutions. As governments and industries worldwide continue to prioritize environmental sustainability, the demand for electric commercial vehicles is expected to grow, driving further innovation and adoption of cell to chassis technology. Overall, the application of Global Cell to Chassis Technology Market in both passenger cars and commercial vehicles underscores its potential to revolutionize the automotive industry, offering a pathway to more efficient, sustainable, and high-performing vehicles.

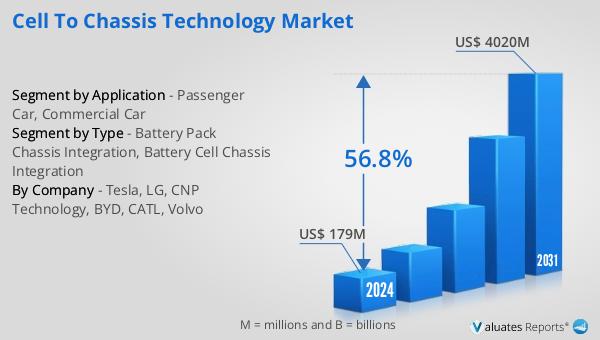

Global Cell to Chassis Technology Market Outlook:

The outlook for the Global Cell to Chassis Technology Market is promising, with projections indicating significant growth in the coming years. The market is expected to expand from $179 million in 2024 to a staggering $4,020 million by 2031, reflecting a compound annual growth rate (CAGR) of 56.8% from 2025 to 2031. This remarkable growth is driven by the increasing demand for electric vehicles and the critical role that cell to chassis technology plays in enhancing their performance and efficiency. As automakers continue to innovate and explore new ways to integrate battery systems into vehicle designs, the potential for cell to chassis technology to transform the automotive landscape is immense. The diverse applications of this technology, from passenger cars to commercial vehicles, further underscore its versatility and appeal. By offering solutions that address key challenges such as weight reduction, energy efficiency, and structural integrity, cell to chassis technology is poised to become a cornerstone of the electric vehicle market. As the industry evolves and consumer preferences shift towards more sustainable and efficient transportation options, the Global Cell to Chassis Technology Market is well-positioned to capitalize on these trends and drive the future of mobility.

| Report Metric | Details |

| Report Name | Cell to Chassis Technology Market |

| Accounted market size in 2024 | US$ 179 million |

| Forecasted market size in 2031 | US$ 4020 million |

| CAGR | 56.8% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Sales by Region |

|

| By Company | Tesla, LG, CNP Technology, BYD, CATL, Volvo |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |