What is Global Cyclone Dry Air Scrubbers Market?

The Global Cyclone Dry Air Scrubbers Market is a specialized segment within the broader air pollution control industry. These scrubbers are designed to remove particulates and pollutants from air streams, primarily using centrifugal forces. Unlike wet scrubbers, which use liquids to capture pollutants, cyclone dry air scrubbers rely on a mechanical process that involves spinning the air stream at high speeds. This spinning action forces heavier particles to the outer edges of the cyclone chamber, where they are collected and removed. The market for these scrubbers is driven by increasing environmental regulations and the need for industries to reduce their emissions. Industries such as manufacturing, energy, and chemicals are significant users of these systems, as they often produce large volumes of air pollutants. The demand for cyclone dry air scrubbers is also fueled by advancements in technology that have made these systems more efficient and cost-effective. As industries continue to seek sustainable and compliant solutions for air quality management, the market for cyclone dry air scrubbers is expected to grow.

Reverse Flow Gas Cyclone Separator, Uniflow Gas Cyclone Separator in the Global Cyclone Dry Air Scrubbers Market:

In the realm of cyclone dry air scrubbers, two prominent types are the Reverse Flow Gas Cyclone Separator and the Uniflow Gas Cyclone Separator. The Reverse Flow Gas Cyclone Separator is a widely used design in which the gas stream enters the cyclone chamber tangentially, creating a spiral motion. As the gas spirals downward, centrifugal forces push the heavier particles toward the outer walls of the chamber. These particles then fall into a collection hopper at the bottom. The cleaned gas reverses direction and exits through a central outlet at the top. This design is favored for its simplicity and effectiveness in removing larger particles. However, it may not be as efficient for capturing very fine particles, which can be a limitation in certain applications. On the other hand, the Uniflow Gas Cyclone Separator operates on a slightly different principle. In this design, the gas stream enters the cyclone chamber axially, meaning it flows straight down the center. The centrifugal forces still act to push particles outward, but the flow pattern is more streamlined. This can result in lower pressure drops and potentially higher efficiency for certain particle sizes. The Uniflow design is often used in applications where minimizing pressure loss is critical. Both types of cyclone separators have their advantages and disadvantages, and the choice between them often depends on the specific requirements of the application, such as the size and type of particles to be removed, the desired efficiency, and the acceptable pressure drop. In the Global Cyclone Dry Air Scrubbers Market, these separators play a crucial role in helping industries meet environmental regulations and improve air quality. As technology continues to advance, we can expect further innovations in cyclone separator designs, potentially leading to even more efficient and versatile systems.

Environmental Protection, Machinery Manufacturing, Energy and Chemical, Others in the Global Cyclone Dry Air Scrubbers Market:

The Global Cyclone Dry Air Scrubbers Market finds its applications across various sectors, each with its unique requirements and challenges. In the field of Environmental Protection, these scrubbers are essential for reducing air pollution and ensuring compliance with stringent environmental regulations. Industries that emit large volumes of particulate matter, such as cement manufacturing and mining, rely on cyclone dry air scrubbers to capture and remove these pollutants before they are released into the atmosphere. This not only helps in protecting the environment but also in safeguarding public health by reducing the incidence of respiratory diseases associated with air pollution. In Machinery Manufacturing, cyclone dry air scrubbers are used to maintain clean air within production facilities. Manufacturing processes often generate dust and other airborne particles that can affect the quality of the final product and the health of workers. By using cyclone scrubbers, manufacturers can ensure a cleaner working environment, which can lead to improved product quality and worker safety. In the Energy and Chemical sectors, these scrubbers are crucial for controlling emissions from combustion processes and chemical reactions. Power plants, refineries, and chemical manufacturing facilities often produce significant amounts of particulate emissions. Cyclone dry air scrubbers help in capturing these particles, thereby reducing the environmental impact and ensuring compliance with emission standards. Additionally, in other sectors such as food processing and pharmaceuticals, cyclone scrubbers are used to maintain air quality and prevent contamination. The versatility and efficiency of cyclone dry air scrubbers make them an indispensable tool in various industries, contributing to cleaner air and a healthier environment.

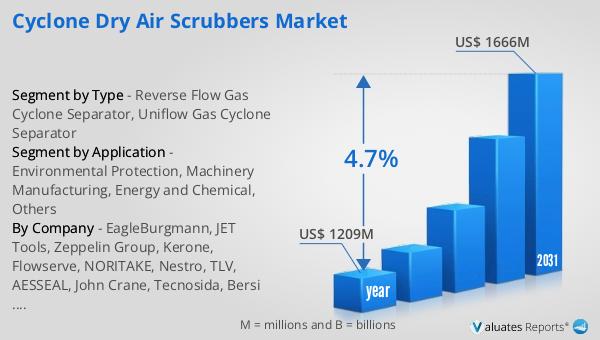

Global Cyclone Dry Air Scrubbers Market Outlook:

The global market for Cyclone Dry Air Scrubbers was valued at approximately $1,209 million in 2024. It is anticipated to grow to a revised size of around $1,666 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.7% over the forecast period. This growth is indicative of the increasing demand for effective air pollution control solutions across various industries. As environmental regulations become more stringent and industries seek to reduce their carbon footprint, the need for efficient and cost-effective air scrubbers is on the rise. Cyclone dry air scrubbers, with their ability to remove particulates without the use of water or chemicals, offer a sustainable solution for industries looking to improve their environmental performance. The projected growth in the market also suggests that technological advancements and innovations in cyclone scrubber designs are likely to continue, further enhancing their efficiency and appeal. As industries worldwide prioritize sustainability and compliance, the market for cyclone dry air scrubbers is poised for significant expansion.

| Report Metric | Details |

| Report Name | Cyclone Dry Air Scrubbers Market |

| Accounted market size in year | US$ 1209 million |

| Forecasted market size in 2031 | US$ 1666 million |

| CAGR | 4.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | EagleBurgmann, JET Tools, Zeppelin Group, Kerone, Flowserve, NORITAKE, Nestro, TLV, AESSEAL, John Crane, Tecnosida, Bersi Industrial, Hastings Air Energy, BOGE Compressors, Paul Gothe GmbH, Rees-Memphis, Hanningfield, APCINFRA, US Systems |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |