What is Global Motor Hook Up Wire Market?

The Global Motor Hook Up Wire Market is a specialized segment within the broader electrical wire industry, focusing on wires used to connect various components within motors. These wires are essential for ensuring the efficient transmission of electrical signals and power within motor systems, which are integral to numerous applications across industries. The market encompasses a variety of wire types, each designed to meet specific requirements such as temperature resistance, flexibility, and durability. As industries continue to advance technologically, the demand for high-performance motor hook up wires is increasing, driven by the need for reliable and efficient motor operations. This market is characterized by continuous innovation, with manufacturers striving to develop wires that can withstand harsh environments and deliver optimal performance. The growth of this market is also influenced by the expansion of industries such as automotive, aerospace, and industrial machinery, where motors play a crucial role. As a result, the Global Motor Hook Up Wire Market is poised for significant growth, driven by technological advancements and the increasing complexity of motor systems.

Direct Hook Up Wire, Lead Box Type Hook Up Wire in the Global Motor Hook Up Wire Market:

Direct Hook Up Wire and Lead Box Type Hook Up Wire are two prominent categories within the Global Motor Hook Up Wire Market, each serving distinct purposes and applications. Direct Hook Up Wire is typically used for internal wiring of electrical and electronic equipment, where flexibility and insulation are crucial. These wires are designed to handle a range of voltages and are often used in environments where space is limited, requiring wires that can bend and fit into tight spaces without compromising performance. The insulation on Direct Hook Up Wires is often made from materials like PVC, Teflon, or silicone, providing resistance to heat, moisture, and chemicals, which is essential for maintaining the integrity of the wire in various conditions. On the other hand, Lead Box Type Hook Up Wire is used in applications where more robust protection is needed. These wires are often encased in a protective lead box, which shields them from external factors such as mechanical stress, electromagnetic interference, and environmental hazards. This makes them ideal for use in harsh environments where reliability and durability are paramount. The choice between Direct Hook Up Wire and Lead Box Type Hook Up Wire depends on the specific requirements of the application, including factors such as environmental conditions, space constraints, and the level of protection needed. As the Global Motor Hook Up Wire Market continues to evolve, manufacturers are focusing on developing wires that offer enhanced performance, greater flexibility, and improved resistance to environmental factors. This includes the use of advanced materials and manufacturing techniques to produce wires that can meet the demands of modern motor systems. The increasing complexity of motor applications, driven by advancements in technology and the need for more efficient and reliable systems, is fueling the demand for high-quality hook up wires. As a result, both Direct Hook Up Wire and Lead Box Type Hook Up Wire are expected to see significant growth in the coming years, as industries continue to seek out solutions that can meet their evolving needs.

DC Motor, AC Motor in the Global Motor Hook Up Wire Market:

The usage of Global Motor Hook Up Wire Market in DC Motors and AC Motors is crucial for ensuring the efficient operation of these motor systems. In DC Motors, hook up wires are used to connect the various components within the motor, including the armature, field windings, and brushes. These wires must be able to handle the high currents and voltages associated with DC motor operation, while also providing flexibility and durability to withstand the mechanical stresses of the motor environment. The insulation on these wires is critical for preventing short circuits and ensuring the safe operation of the motor. In AC Motors, hook up wires are used to connect the stator windings, rotor, and other components. These wires must be able to handle the alternating currents and varying voltages associated with AC motor operation, while also providing resistance to heat and electromagnetic interference. The insulation on these wires is essential for maintaining the integrity of the motor system and preventing electrical faults. The choice of hook up wire for AC Motors depends on factors such as the operating environment, the power requirements of the motor, and the level of protection needed. As the demand for more efficient and reliable motor systems continues to grow, the Global Motor Hook Up Wire Market is seeing increased demand for wires that can meet the specific needs of both DC and AC Motors. This includes the development of wires with enhanced performance characteristics, such as improved flexibility, greater resistance to environmental factors, and the ability to handle higher currents and voltages. As industries continue to advance technologically, the need for high-quality hook up wires in motor applications is expected to grow, driving the expansion of the Global Motor Hook Up Wire Market.

Global Motor Hook Up Wire Market Outlook:

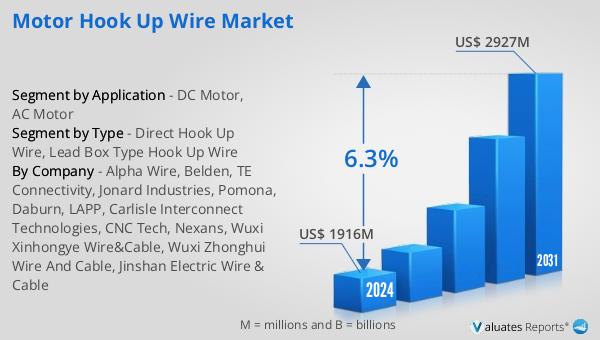

The outlook for the Global Motor Hook Up Wire Market indicates a promising growth trajectory, with the market expected to expand from $1,916 million in 2024 to $2,927 million by 2031, reflecting a compound annual growth rate (CAGR) of 6.3% from 2025 to 2031. This growth is driven by the increasing demand for critical product segments and diverse end-use applications across various industries. As technological advancements continue to shape the landscape of motor systems, the need for high-performance hook up wires is becoming more pronounced. These wires are essential for ensuring the efficient and reliable operation of motors, which are integral to numerous applications in industries such as automotive, aerospace, and industrial machinery. However, the evolving U.S. tariff policies are introducing trade-cost volatility and supply-chain uncertainty, which could impact the market dynamics. Despite these challenges, the Global Motor Hook Up Wire Market is poised for significant growth, driven by the increasing complexity of motor systems and the need for more efficient and reliable solutions. As manufacturers continue to innovate and develop wires that can meet the evolving needs of modern motor applications, the market is expected to see continued expansion in the coming years.

| Report Metric | Details |

| Report Name | Motor Hook Up Wire Market |

| Accounted market size in 2024 | US$ 1916 in million |

| Forecasted market size in 2031 | US$ 2927 million |

| CAGR | 6.3% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Alpha Wire, Belden, TE Connectivity, Jonard Industries, Pomona, Daburn, LAPP, Carlisle Interconnect Technologies, CNC Tech, Nexans, Wuxi Xinhongye Wire&Cable, Wuxi Zhonghui Wire And Cable, Jinshan Electric Wire & Cable |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |