What is Global High Chrome Cast Grinding Media Market?

The Global High Chrome Cast Grinding Media Market is a specialized segment within the broader industrial sector, focusing on the production and distribution of high-quality grinding media. These grinding media are primarily used in the mining, cement, and power plant industries to crush or grind materials into smaller particles. High chrome cast grinding media are preferred due to their superior wear resistance, hardness, and durability, which enhance the efficiency and longevity of grinding processes. The market is characterized by a diverse range of products, including balls, cylinders, and other shapes, each designed to meet specific industrial needs. The demand for high chrome cast grinding media is driven by the increasing need for efficient grinding solutions in various industries, coupled with the growing emphasis on cost-effective and sustainable production methods. As industries continue to expand and modernize, the market for high chrome cast grinding media is expected to grow, offering numerous opportunities for manufacturers and suppliers to innovate and meet evolving customer demands. The market's growth is also influenced by technological advancements and the development of new materials that enhance the performance and lifespan of grinding media.

Diameter Below 30 mm, Diameter Above 30 mm in the Global High Chrome Cast Grinding Media Market:

In the Global High Chrome Cast Grinding Media Market, the diameter of the grinding media plays a crucial role in determining its application and effectiveness. Grinding media with a diameter below 30 mm are typically used in fine grinding applications where precision and efficiency are paramount. These smaller diameter media are ideal for industries that require a high degree of fineness in their final product, such as the paint and pigment industry, where achieving a smooth and consistent texture is essential. The smaller size allows for a greater surface area contact with the material being ground, leading to faster and more efficient grinding processes. On the other hand, grinding media with a diameter above 30 mm are generally used in coarse grinding applications where the primary goal is to break down larger chunks of material into smaller, more manageable pieces. These larger diameter media are commonly used in the mining and cement industries, where the initial size reduction of raw materials is a critical step in the production process. The larger size of these media allows them to exert greater force on the material being ground, making them ideal for breaking down tough and abrasive materials. The choice between smaller and larger diameter grinding media depends on several factors, including the nature of the material being ground, the desired final particle size, and the specific requirements of the grinding process. Manufacturers in the Global High Chrome Cast Grinding Media Market must carefully consider these factors when designing and producing their products to ensure they meet the needs of their customers. Additionally, advancements in manufacturing technology have enabled the production of grinding media with precise diameter specifications, allowing for greater customization and optimization of the grinding process. This has led to increased efficiency and cost savings for industries that rely on high chrome cast grinding media for their operations. As the market continues to evolve, the demand for both smaller and larger diameter grinding media is expected to grow, driven by the need for more efficient and effective grinding solutions across various industries.

Mining and Metallurgy, Cement, Power Plant, Others in the Global High Chrome Cast Grinding Media Market:

The Global High Chrome Cast Grinding Media Market finds extensive usage across several key industries, including mining and metallurgy, cement, power plants, and others. In the mining and metallurgy sector, high chrome cast grinding media are essential for the extraction and processing of minerals. They are used in grinding mills to crush and grind ores into fine particles, facilitating the extraction of valuable metals. The superior wear resistance and hardness of high chrome cast grinding media make them ideal for the harsh conditions of mining operations, where they must withstand significant abrasion and impact. In the cement industry, high chrome cast grinding media are used in ball mills to grind clinker and other raw materials into the fine powder required for cement production. The efficiency and durability of these grinding media contribute to the overall productivity and cost-effectiveness of cement manufacturing processes. In power plants, high chrome cast grinding media are used in coal pulverizers to grind coal into a fine powder for combustion in boilers. The high wear resistance of these media ensures a longer lifespan and reduced maintenance costs, contributing to the overall efficiency of power generation. Other industries that utilize high chrome cast grinding media include the chemical and paint industries, where they are used to grind pigments and other materials into fine particles. The versatility and effectiveness of high chrome cast grinding media make them a valuable asset in a wide range of industrial applications, driving demand and growth in the market. As industries continue to seek more efficient and sustainable production methods, the use of high chrome cast grinding media is expected to increase, offering numerous opportunities for manufacturers and suppliers to innovate and meet evolving customer needs.

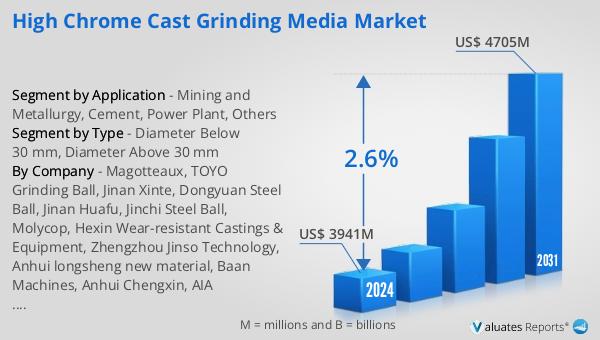

Global High Chrome Cast Grinding Media Market Outlook:

The outlook for the Global High Chrome Cast Grinding Media Market indicates a steady growth trajectory, with the market expected to expand from $3,941 million in 2024 to $4,705 million by 2031, reflecting a compound annual growth rate (CAGR) of 2.6% from 2025 to 2031. This growth is driven by the increasing demand for high-quality grinding media across various industries, including mining, cement, and power generation. The market's expansion is supported by the development of critical product segments that cater to the specific needs of these industries, offering enhanced performance and efficiency. Additionally, the diverse range of end-use applications for high chrome cast grinding media contributes to the market's growth, as industries continue to seek more effective and sustainable grinding solutions. However, the market also faces challenges, particularly in the form of evolving U.S. tariff policies, which introduce trade cost volatility and supply chain uncertainty. These factors may impact the availability and pricing of raw materials, affecting the overall production and distribution of high chrome cast grinding media. Despite these challenges, the market is expected to continue its growth trajectory, driven by the ongoing demand for efficient and durable grinding solutions in various industries. Manufacturers and suppliers in the Global High Chrome Cast Grinding Media Market must navigate these challenges while capitalizing on the opportunities presented by the growing demand for their products.

| Report Metric | Details |

| Report Name | High Chrome Cast Grinding Media Market |

| Accounted market size in 2024 | US$ 3941 million |

| Forecasted market size in 2031 | US$ 4705 million |

| CAGR | 2.6% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Magotteaux, TOYO Grinding Ball, Jinan Xinte, Dongyuan Steel Ball, Jinan Huafu, Jinchi Steel Ball, Molycop, Hexin Wear-resistant Castings & Equipment, Zhengzhou Jinso Technology, Anhui longsheng new material, Baan Machines, Anhui Chengxin, AIA Engineering, Litzkuhn & Niederwipper |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |