What is Global Hydraulic Tyre Vulcanizing Press Machine Market?

The Global Hydraulic Tyre Vulcanizing Press Machine Market is a specialized segment within the broader machinery industry, focusing on the production and maintenance of vulcanizing presses used in tire manufacturing. These machines play a crucial role in the tire production process by applying heat and pressure to cure rubber, transforming it into durable and elastic tires. The market is driven by the increasing demand for vehicles, which in turn boosts the need for tires, thereby propelling the demand for vulcanizing machines. Technological advancements have led to the development of more efficient and automated machines, enhancing productivity and reducing labor costs. Additionally, the market is influenced by the growing emphasis on sustainable and eco-friendly manufacturing processes, prompting manufacturers to innovate and improve their machinery. The global reach of this market is significant, with key players operating across various regions, catering to both established and emerging markets. As the automotive industry continues to evolve, the demand for high-quality tires and, consequently, advanced vulcanizing machines is expected to rise, making this market a vital component of the global manufacturing landscape.

Frame Type, Column Type in the Global Hydraulic Tyre Vulcanizing Press Machine Market:

In the Global Hydraulic Tyre Vulcanizing Press Machine Market, two prominent types of machines are the Frame Type and Column Type. The Frame Type vulcanizing press is characterized by its robust structure, which provides stability and uniform pressure distribution during the vulcanization process. This type of machine is particularly favored for its ability to handle large-scale production with high precision and efficiency. The frame structure ensures that the machine can withstand the high pressures and temperatures required for vulcanizing tires, making it a reliable choice for manufacturers aiming for consistent quality. On the other hand, the Column Type vulcanizing press is designed with vertical columns that support the press plates. This design allows for easy access and maintenance, making it a preferred choice for operations that require frequent adjustments or servicing. The Column Type is often used in smaller production setups or for specialized tire types where flexibility and ease of use are prioritized. Both types of machines are integral to the tire manufacturing process, each offering unique advantages that cater to different production needs. The choice between Frame Type and Column Type machines often depends on factors such as production volume, tire specifications, and operational preferences. As the market continues to grow, manufacturers are investing in research and development to enhance the capabilities of both machine types, focusing on automation, energy efficiency, and precision. This ongoing innovation is crucial in meeting the evolving demands of the automotive industry, where the quality and performance of tires are of paramount importance. The competition between Frame Type and Column Type machines drives technological advancements, ensuring that the market remains dynamic and responsive to industry needs. As a result, manufacturers are able to offer a diverse range of machines that cater to various production requirements, from high-volume industrial operations to specialized, small-scale manufacturing. This diversity is a testament to the adaptability and resilience of the Global Hydraulic Tyre Vulcanizing Press Machine Market, which continues to thrive amidst changing industry trends and consumer preferences.

All - steel Radial Tires, Semi - steel Radial Tires, Full - fiber Radial Tires in the Global Hydraulic Tyre Vulcanizing Press Machine Market:

The Global Hydraulic Tyre Vulcanizing Press Machine Market finds extensive application in the production of various types of radial tires, including All-steel Radial Tires, Semi-steel Radial Tires, and Full-fiber Radial Tires. All-steel Radial Tires are known for their durability and strength, making them ideal for heavy-duty vehicles such as trucks and buses. The vulcanizing press machines used in their production are designed to handle the high pressures and temperatures required to cure the steel-reinforced rubber, ensuring that the tires meet the stringent performance standards demanded by the automotive industry. Semi-steel Radial Tires, which combine steel and fabric reinforcements, offer a balance between strength and flexibility. The vulcanizing process for these tires requires precise control to ensure that the different materials bond effectively, resulting in a tire that provides both durability and comfort. The versatility of hydraulic vulcanizing press machines makes them well-suited for this task, as they can be adjusted to accommodate the specific requirements of semi-steel tires. Full-fiber Radial Tires, on the other hand, are designed for lighter vehicles and prioritize comfort and fuel efficiency. The vulcanizing process for these tires focuses on achieving a uniform cure across the fiber-reinforced rubber, ensuring that the tires deliver optimal performance in terms of ride quality and energy consumption. The adaptability of hydraulic vulcanizing press machines allows manufacturers to fine-tune the curing process, ensuring that full-fiber tires meet the desired specifications. Across all these tire types, the role of hydraulic vulcanizing press machines is critical in ensuring that the final product meets the necessary safety and performance standards. The ability to precisely control the vulcanization process is essential in producing tires that are not only durable and reliable but also tailored to the specific needs of different vehicle types. As the demand for diverse tire options continues to grow, the Global Hydraulic Tyre Vulcanizing Press Machine Market remains a key player in supporting the automotive industry's evolving requirements.

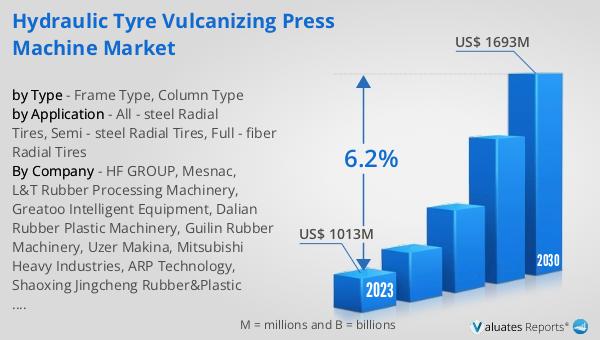

Global Hydraulic Tyre Vulcanizing Press Machine Market Outlook:

The outlook for the Global Hydraulic Tyre Vulcanizing Press Machine Market indicates a promising growth trajectory, with projections suggesting an increase from US$ 1180 million in 2024 to US$ 1787 million by 2031. This growth, at a compound annual growth rate (CAGR) of 6.2% from 2025 to 2031, is driven by the expansion of critical product segments and a wide range of end-use applications. The market's growth is underpinned by the increasing demand for advanced tire manufacturing solutions that cater to the diverse needs of the automotive industry. However, the evolving tariff policies in the U.S. introduce an element of trade cost volatility and supply chain uncertainty, which could impact market dynamics. Despite these challenges, the market is expected to remain resilient, with manufacturers focusing on innovation and efficiency to navigate the complexities of global trade. The emphasis on sustainable manufacturing practices and the development of eco-friendly vulcanizing machines are likely to play a significant role in shaping the market's future. As the industry continues to adapt to changing economic and regulatory landscapes, the Global Hydraulic Tyre Vulcanizing Press Machine Market is poised to capitalize on emerging opportunities and maintain its growth momentum.

| Report Metric | Details |

| Report Name | Hydraulic Tyre Vulcanizing Press Machine Market |

| Accounted market size in 2024 | US$ 1180 million |

| Forecasted market size in 2031 | US$ 1787 million |

| CAGR | 6.2% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | HF GROUP, Mesnac, L&T Rubber Processing Machinery, Greatoo Intelligent Equipment, Dalian Rubber Plastic Machinery, Guilin Rubber Machinery, Uzer Makina, Mitsubishi Heavy Industries, ARP Technology, Shaoxing Jingcheng Rubber&Plastic Machinery, SIMPAC Industrial Machinery, Hebert, AMCL Machinery, Macrodyne Technologies, Himile, Rongsheng Machinery, Yiyang Rubber&Plastics Machinery, Weiling Rubber & Plastics Machinery, DoubleStar Group, Alwin Machinery, Fujian Sanming Shuanglun Chemical Industry Machinery, Desiree Industrial, Zhejiang Rongsheng Machinery, Qingdao Delphy Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |