What is Global Protection Films for Laser Cutting Market?

The Global Protection Films for Laser Cutting Market refers to the industry focused on manufacturing and supplying protective films used during laser cutting processes. These films are essential in safeguarding materials from potential damage caused by laser beams, such as scratches, burns, or other surface imperfections. The films are typically applied to the surface of materials like metals, plastics, and glass before the laser cutting process begins. They act as a barrier, absorbing excess heat and preventing debris from settling on the material's surface. This ensures a clean cut and maintains the integrity of the material being processed. The market for these films is driven by the increasing demand for precision cutting in various industries, including automotive, electronics, and construction. As industries continue to adopt laser cutting technology for its efficiency and precision, the need for high-quality protection films is expected to grow. These films not only enhance the quality of the final product but also extend the lifespan of the laser cutting equipment by reducing wear and tear. The market is characterized by continuous innovation, with manufacturers developing films that offer better heat resistance, durability, and ease of application.

70-100um Thickness, >100um Thickness in the Global Protection Films for Laser Cutting Market:

In the Global Protection Films for Laser Cutting Market, the thickness of the films plays a crucial role in determining their suitability for different applications. Films with a thickness of 70-100 micrometers (um) are commonly used for general-purpose applications. These films provide adequate protection for materials that are not subjected to extreme laser power or prolonged exposure. They are ideal for cutting thin sheets of metal, plastic, or glass, where the risk of surface damage is moderate. The 70-100um thickness range offers a balance between protection and flexibility, allowing for easy application and removal without leaving residue. On the other hand, films with a thickness greater than 100um are designed for more demanding applications. These thicker films are used when cutting thicker materials or when higher laser power is required. They offer enhanced protection against heat and debris, ensuring that the material's surface remains pristine even under challenging conditions. The increased thickness provides a robust barrier, making these films suitable for heavy-duty industrial applications where precision and surface quality are paramount. The choice between 70-100um and >100um thickness films depends on several factors, including the material being cut, the laser cutting machine's power, and the desired finish quality. Manufacturers in the market are continually innovating to develop films that cater to the diverse needs of different industries. They focus on improving the films' heat resistance, adhesion properties, and ease of use. As laser cutting technology advances, the demand for specialized protection films with varying thicknesses is expected to rise. This growth is driven by the need for precision and efficiency in industries such as automotive, aerospace, and electronics, where laser cutting is a critical part of the manufacturing process. The market for protection films is also influenced by environmental considerations, with manufacturers exploring eco-friendly materials and production processes. This shift towards sustainability is expected to shape the future of the market, as industries increasingly prioritize environmentally responsible practices. Overall, the Global Protection Films for Laser Cutting Market is characterized by a wide range of products designed to meet the specific needs of different applications, with thickness being a key factor in determining their suitability.

Fiber Laser Cutting Machine, CO2 Laser Cutting Machine in the Global Protection Films for Laser Cutting Market:

The usage of Global Protection Films for Laser Cutting Market in fiber laser cutting machines and CO2 laser cutting machines is integral to ensuring high-quality results and protecting both the material and the equipment. Fiber laser cutting machines are known for their precision and efficiency, making them a popular choice in industries such as automotive, aerospace, and electronics. These machines use a fiber optic cable to deliver the laser beam, which is highly focused and capable of cutting through various materials with ease. Protection films are crucial in this process, as they prevent surface damage and ensure a clean cut. The films act as a barrier, absorbing excess heat and preventing debris from settling on the material's surface. This is particularly important in industries where surface quality is critical, such as in the production of electronic components or automotive parts. The films also help extend the lifespan of the fiber laser cutting machines by reducing wear and tear on the equipment. In CO2 laser cutting machines, protection films play a similar role. These machines use a gas mixture to generate the laser beam, which is then focused onto the material being cut. CO2 lasers are versatile and can cut through a wide range of materials, including metals, plastics, and glass. The use of protection films in CO2 laser cutting machines is essential to prevent surface damage and ensure a high-quality finish. The films protect the material from heat and debris, ensuring that the cut is clean and precise. This is particularly important in industries where precision and surface quality are paramount, such as in the production of medical devices or aerospace components. The choice of protection film depends on several factors, including the material being cut, the laser cutting machine's power, and the desired finish quality. Manufacturers in the market offer a wide range of films designed to meet the specific needs of different applications. They focus on improving the films' heat resistance, adhesion properties, and ease of use. As laser cutting technology advances, the demand for specialized protection films is expected to rise. This growth is driven by the need for precision and efficiency in industries where laser cutting is a critical part of the manufacturing process. Overall, the usage of Global Protection Films for Laser Cutting Market in fiber laser cutting machines and CO2 laser cutting machines is essential to ensuring high-quality results and protecting both the material and the equipment.

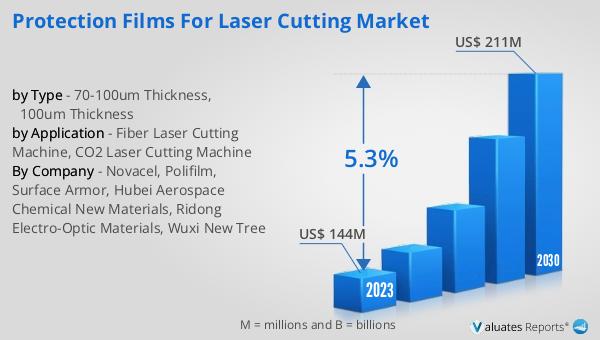

Global Protection Films for Laser Cutting Market Outlook:

The outlook for the global Protection Films for Laser Cutting market indicates a promising growth trajectory, with projections showing an increase from $155 million in 2024 to $221 million by 2031. This growth, at a compound annual growth rate (CAGR) of 5.3% from 2025 to 2031, is largely driven by the critical product segments and the diverse range of end-use applications that these films cater to. As industries continue to adopt laser cutting technology for its precision and efficiency, the demand for high-quality protection films is expected to rise. These films are essential in ensuring the quality and integrity of materials during the laser cutting process, making them indispensable in sectors such as automotive, electronics, and construction. However, the market is not without its challenges. Evolving U.S. tariff policies introduce a level of trade-cost volatility and supply-chain uncertainty that could impact the market dynamics. These policies may affect the cost of raw materials and the overall production costs, potentially influencing the pricing strategies of manufacturers. Despite these challenges, the market's growth prospects remain strong, driven by the continuous innovation and development of films that offer better heat resistance, durability, and ease of application. As industries increasingly prioritize precision and efficiency, the demand for specialized protection films is expected to grow, shaping the future of the market.

| Report Metric | Details |

| Report Name | Protection Films for Laser Cutting Market |

| Accounted market size in 2024 | US$ 155 million |

| Forecasted market size in 2031 | US$ 221 million |

| CAGR | 5.3% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Novacel, Polifilm, Surface Armor, Hubei Aerospace Chemical New Materials, Ridong Electro-Optic Materials, Wuxi New Tree |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |