What is Global PVDC Coating Films Market?

The Global PVDC Coating Films Market is a significant segment within the packaging industry, known for its exceptional barrier properties. PVDC, or polyvinylidene chloride, is a type of plastic that is widely used for coating films to enhance their protective qualities. These films are primarily used in packaging applications where moisture, oxygen, and aroma barriers are crucial. The market for PVDC coating films is driven by the increasing demand for high-performance packaging solutions across various industries, including food, pharmaceuticals, and chemicals. These films are favored for their ability to extend the shelf life of products by preventing contamination and spoilage. Additionally, the growing awareness of sustainable packaging solutions has led to innovations in PVDC films, making them more environmentally friendly. As industries continue to prioritize product safety and quality, the demand for PVDC coating films is expected to rise, making it a vital component of the global packaging market. The market's growth is further supported by advancements in coating technologies and the development of new applications, ensuring that PVDC coating films remain a preferred choice for manufacturers seeking reliable and efficient packaging solutions.

Single-sided Coating, Double-sided Coating in the Global PVDC Coating Films Market:

In the Global PVDC Coating Films Market, the distinction between single-sided and double-sided coatings plays a crucial role in determining the application and effectiveness of the films. Single-sided PVDC coating involves applying the PVDC layer to only one side of the film. This type of coating is typically used when the primary concern is to protect the product from external factors such as moisture and oxygen. Single-sided coatings are often employed in packaging applications where one side of the film needs to maintain a high barrier while the other side may require different properties, such as printability or sealability. This makes single-sided PVDC films ideal for packaging food products, where the inner side of the packaging needs to be food-safe and the outer side can be used for branding and information. On the other hand, double-sided PVDC coating involves applying the PVDC layer to both sides of the film. This type of coating is used when there is a need for enhanced barrier properties on both sides of the packaging. Double-sided coatings are particularly useful in applications where the packaged product is sensitive to both internal and external factors. For instance, in the pharmaceutical industry, double-sided PVDC films are used to ensure that medications are protected from moisture and oxygen ingress from both sides, thereby maintaining their efficacy and shelf life. Similarly, in the chemical industry, double-sided coatings provide an added layer of protection for volatile or sensitive substances, ensuring that they remain stable during storage and transportation. The choice between single-sided and double-sided PVDC coatings depends on several factors, including the nature of the product being packaged, the required shelf life, and the environmental conditions to which the packaging will be exposed. Single-sided coatings are generally more cost-effective and are suitable for products that do not require extensive protection. However, for products that are highly sensitive or have a long shelf life, double-sided coatings offer superior protection and are worth the additional investment. The versatility of PVDC coatings allows manufacturers to tailor their packaging solutions to meet specific needs, ensuring that products are adequately protected while also optimizing costs. Furthermore, the development of advanced coating technologies has expanded the possibilities for PVDC films. Innovations in coating processes have led to the creation of thinner, more efficient films that provide the same level of protection as thicker films. This not only reduces material costs but also contributes to sustainability efforts by minimizing waste. Additionally, the ability to customize the properties of PVDC coatings, such as their thickness, adhesion, and clarity, allows manufacturers to create packaging solutions that are not only functional but also aesthetically pleasing. In conclusion, the Global PVDC Coating Films Market offers a range of options for manufacturers seeking reliable and effective packaging solutions. Whether opting for single-sided or double-sided coatings, the key is to understand the specific requirements of the product and the conditions it will face. By leveraging the unique properties of PVDC coatings, manufacturers can ensure that their products are protected, preserved, and presented in the best possible way. As the demand for high-performance packaging continues to grow, the role of PVDC coating films in the global market is set to become increasingly important.

Food, Medicine, Chemicals, Others in the Global PVDC Coating Films Market:

The Global PVDC Coating Films Market finds extensive usage across various sectors, including food, medicine, chemicals, and others, due to its superior barrier properties. In the food industry, PVDC coating films are widely used to package perishable items such as meats, cheeses, and snacks. The films' ability to block moisture and oxygen helps in preserving the freshness and flavor of food products, thereby extending their shelf life. This is particularly important in reducing food waste and ensuring that consumers receive high-quality products. Additionally, PVDC films are used in the packaging of ready-to-eat meals and convenience foods, where maintaining the integrity of the product is crucial. In the pharmaceutical sector, PVDC coating films play a vital role in ensuring the safety and efficacy of medications. These films are used to package tablets, capsules, and other dosage forms that are sensitive to moisture and oxygen. By providing a robust barrier, PVDC films help in maintaining the stability of active pharmaceutical ingredients, thereby ensuring that medications remain effective throughout their shelf life. This is particularly important for medications that are stored for extended periods or transported across different climates. The use of PVDC films in blister packaging is a common application in the pharmaceutical industry, providing both protection and convenience for consumers. The chemical industry also benefits from the use of PVDC coating films, particularly in the packaging of volatile or sensitive substances. The films' barrier properties help in preventing the ingress of moisture and oxygen, which can lead to chemical degradation or reactions. This is crucial for maintaining the stability and safety of chemical products during storage and transportation. PVDC films are used in the packaging of a wide range of chemical products, including solvents, adhesives, and specialty chemicals, where maintaining product integrity is essential. Beyond these primary sectors, PVDC coating films are also used in various other applications. For instance, in the electronics industry, these films are used to package sensitive components that require protection from moisture and static. In the personal care industry, PVDC films are used in the packaging of products such as cosmetics and toiletries, where maintaining product freshness and preventing contamination are important. The versatility of PVDC films makes them suitable for a wide range of applications, providing manufacturers with a reliable solution for protecting their products. Overall, the Global PVDC Coating Films Market plays a crucial role in enhancing the quality and safety of products across various industries. By providing an effective barrier against environmental factors, these films help in preserving the integrity of products, reducing waste, and ensuring consumer satisfaction. As industries continue to prioritize product safety and quality, the demand for PVDC coating films is expected to grow, further solidifying their position as a key component of the global packaging market.

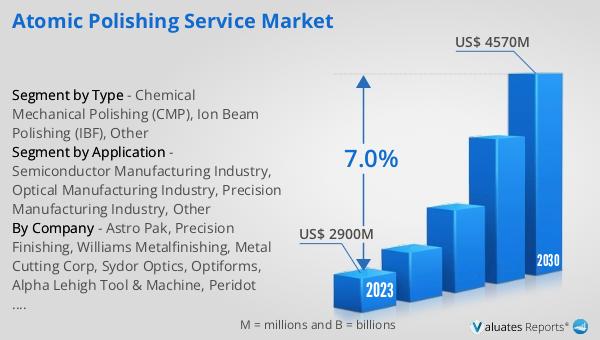

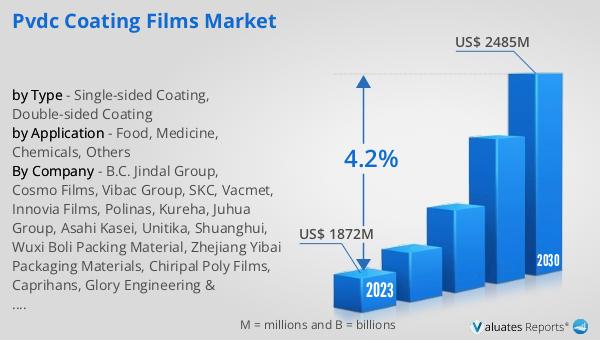

Global PVDC Coating Films Market Outlook:

The outlook for the Global PVDC Coating Films Market indicates a promising growth trajectory, with projections showing an increase from $1,947 million in 2024 to $2,578 million by 2031. This growth, at a compound annual growth rate (CAGR) of 4.2% from 2025 to 2031, is driven by the expanding demand for PVDC films across various critical product segments and diverse end-use applications. The market's expansion is fueled by the increasing need for high-performance packaging solutions that offer superior barrier properties, particularly in industries such as food, pharmaceuticals, and chemicals. As these industries continue to grow and evolve, the demand for reliable and efficient packaging solutions is expected to rise, further driving the market for PVDC coating films. However, the market's growth is not without challenges. Evolving U.S. tariff policies have introduced trade-cost volatility and supply-chain uncertainty, which could impact the market dynamics. These changes in trade policies may lead to fluctuations in raw material costs and affect the overall supply chain, posing challenges for manufacturers in maintaining cost-effectiveness and efficiency. Despite these challenges, the market's growth prospects remain strong, supported by ongoing innovations in coating technologies and the development of new applications for PVDC films. In conclusion, the Global PVDC Coating Films Market is poised for significant growth in the coming years, driven by the increasing demand for high-performance packaging solutions across various industries. While challenges such as trade-cost volatility and supply-chain uncertainty may pose hurdles, the market's resilience and adaptability are expected to ensure continued growth and development. As manufacturers continue to innovate and adapt to changing market conditions, the role of PVDC coating films in the global packaging industry is set to become increasingly important.

| Report Metric | Details |

| Report Name | PVDC Coating Films Market |

| Accounted market size in 2024 | US$ 1947 million |

| Forecasted market size in 2031 | US$ 2578 million |

| CAGR | 4.2% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | B.C. Jindal Group, Cosmo Films, Vibac Group, SKC, Vacmet, Innovia Films, Polinas, Kureha, Juhua Group, Asahi Kasei, Unitika, Shuanghui, Wuxi Boli Packing Material, Zhejiang Yibai Packaging Materials, Chiripal Poly Films, Caprihans, Glory Engineering & Technology, Supuratama, HangZhou Chalvo, Linyi Jinluo |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |