What is Global Wax Pattern 3D Printer Market?

The Global Wax Pattern 3D Printer Market is an emerging sector within the broader 3D printing industry, focusing specifically on the production of wax patterns. These printers are primarily used in industries that require precision casting, such as jewelry, medical devices, and art. Wax pattern 3D printers utilize advanced technologies to create detailed and intricate designs that serve as molds for casting metals and other materials. The market is driven by the increasing demand for customized and complex designs that traditional manufacturing methods struggle to produce efficiently. As industries continue to seek innovative solutions for prototyping and production, the adoption of wax pattern 3D printers is expected to rise. These printers offer significant advantages, including reduced material waste, faster production times, and the ability to produce highly detailed and accurate patterns. The market is also influenced by technological advancements that enhance the capabilities and efficiency of these printers, making them more accessible to a wider range of industries. As a result, the Global Wax Pattern 3D Printer Market is poised for growth, driven by the need for precision and customization in manufacturing processes.

Semi Automatic, Fully Automatic in the Global Wax Pattern 3D Printer Market:

In the Global Wax Pattern 3D Printer Market, the distinction between semi-automatic and fully automatic printers is significant, as it influences the efficiency, cost, and usability of the technology. Semi-automatic wax pattern 3D printers require some level of human intervention during the printing process. This might involve manual setup, monitoring, or post-processing tasks. These printers are often favored by smaller businesses or workshops that have skilled operators who can manage the intricacies of the printing process. The semi-automatic models are generally more affordable than their fully automatic counterparts, making them accessible to a broader range of users. They offer flexibility and control, allowing operators to make adjustments during the printing process to achieve the desired results. However, the reliance on human intervention can also lead to inconsistencies in output and longer production times, especially if the operator lacks experience or expertise. On the other hand, fully automatic wax pattern 3D printers are designed to operate with minimal human intervention. These printers are equipped with advanced software and sensors that automate the entire printing process, from setup to completion. This automation ensures consistent quality and precision, as the printer can make real-time adjustments based on the data it receives. Fully automatic printers are ideal for large-scale production environments where efficiency and consistency are paramount. They reduce the risk of human error and can significantly speed up the production process, making them a valuable asset for industries that require high volumes of wax patterns. However, the initial investment for fully automatic printers is typically higher, which can be a barrier for smaller businesses or those new to 3D printing technology. The choice between semi-automatic and fully automatic wax pattern 3D printers depends largely on the specific needs and resources of the user. For businesses that prioritize flexibility and cost-effectiveness, semi-automatic printers may be the preferred option. These printers allow for a hands-on approach, where skilled operators can fine-tune the process to meet specific requirements. This can be particularly beneficial in industries where customization and unique designs are essential. Conversely, for companies that require high throughput and consistent quality, fully automatic printers offer a more efficient solution. The automation reduces the need for skilled labor and minimizes the potential for errors, resulting in a more streamlined production process. In conclusion, both semi-automatic and fully automatic wax pattern 3D printers have their own advantages and limitations. The decision to invest in one type over the other should be based on a careful assessment of the business's production needs, budget, and long-term goals. As the Global Wax Pattern 3D Printer Market continues to evolve, advancements in technology may further blur the lines between these two categories, offering even more options for businesses seeking to leverage 3D printing for wax pattern production.

Jewelry Manufacturing, Medical, Art, Archaeology, Others in the Global Wax Pattern 3D Printer Market:

The Global Wax Pattern 3D Printer Market finds diverse applications across various industries, each benefiting from the unique capabilities of this technology. In jewelry manufacturing, wax pattern 3D printers are revolutionizing the way intricate designs are created. Traditional methods of jewelry making often involve labor-intensive processes that can limit creativity and precision. With 3D printing, jewelers can produce highly detailed wax patterns that serve as molds for casting precious metals. This not only speeds up the production process but also allows for greater design flexibility, enabling jewelers to offer customized pieces that meet the specific preferences of their clients. The precision and accuracy of 3D printed wax patterns ensure that the final product is of the highest quality, with intricate details and smooth finishes. In the medical field, wax pattern 3D printers are used to create models for surgical planning and the production of medical devices. Surgeons can use these models to better understand complex anatomical structures, allowing for more precise and effective surgical interventions. Additionally, the ability to produce customized medical devices, such as prosthetics and implants, is greatly enhanced by 3D printing technology. Wax patterns serve as the initial step in the casting process, ensuring that the final product is tailored to the specific needs of the patient. This level of customization is particularly important in the medical field, where individual patient requirements can vary significantly. The art world has also embraced wax pattern 3D printers as a tool for creating intricate sculptures and installations. Artists can experiment with complex geometries and designs that would be difficult or impossible to achieve using traditional sculpting techniques. The precision of 3D printing allows for the creation of detailed and delicate structures, expanding the possibilities for artistic expression. Furthermore, the ability to produce multiple copies of a design enables artists to explore variations and iterations, pushing the boundaries of their creative work. In archaeology, wax pattern 3D printers are used to replicate artifacts and create detailed models for study and preservation. These replicas can be used for educational purposes, allowing researchers and students to examine and interact with artifacts without risking damage to the original pieces. The accuracy of 3D printed wax patterns ensures that even the smallest details of an artifact are captured, providing valuable insights into historical and cultural contexts. This technology also aids in the preservation of fragile artifacts, as digital models can be stored and reproduced as needed. Beyond these specific industries, wax pattern 3D printers have applications in various other fields, including automotive, aerospace, and consumer goods. The ability to produce precise and complex patterns makes this technology valuable for prototyping and production in any industry that requires detailed casting. As the Global Wax Pattern 3D Printer Market continues to grow, its applications are likely to expand, offering new opportunities for innovation and efficiency across a wide range of sectors.

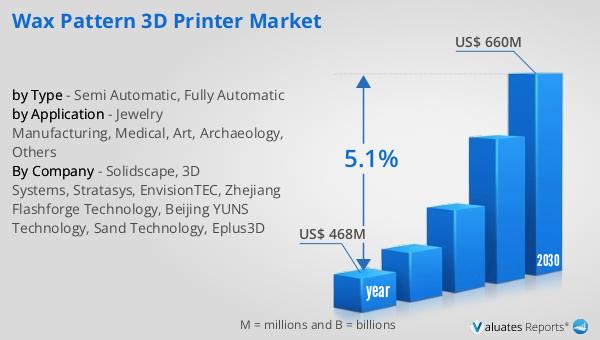

Global Wax Pattern 3D Printer Market Outlook:

The outlook for the Global Wax Pattern 3D Printer Market indicates a promising growth trajectory, with projections suggesting an increase from $490 million in 2024 to $690 million by 2031. This growth, at a compound annual growth rate (CAGR) of 5.1% from 2025 to 2031, is driven by the demand for critical product segments and a variety of end-use applications. Industries such as jewelry manufacturing, medical, and art are increasingly adopting wax pattern 3D printers to enhance their production capabilities and meet the growing demand for customized and intricate designs. However, the market is not without its challenges. Evolving U.S. tariff policies introduce a level of trade cost volatility and supply chain uncertainty that could impact the market's growth. These policies may affect the cost of importing and exporting 3D printing equipment and materials, potentially leading to fluctuations in pricing and availability. Despite these challenges, the market's potential for growth remains strong, as technological advancements continue to improve the efficiency and capabilities of wax pattern 3D printers. As industries seek innovative solutions to enhance their production processes, the Global Wax Pattern 3D Printer Market is well-positioned to capitalize on these opportunities, driving further adoption and expansion across various sectors.

| Report Metric | Details |

| Report Name | Wax Pattern 3D Printer Market |

| Accounted market size in 2024 | US$ 490 million |

| Forecasted market size in 2031 | US$ 690 million |

| CAGR | 5.1% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Solidscape, 3D Systems, Stratasys, EnvisionTEC, Zhejiang Flashforge Technology, Beijing YUNS Technology, Sand Technology, Eplus3D |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |