What is Global Resin Blending System Market?

The Global Resin Blending System Market is a specialized segment within the industrial machinery sector that focuses on the production and distribution of systems designed to blend various types of resins. Resins are crucial materials used in a wide range of industries, including plastics, automotive, construction, and electronics, due to their versatile properties such as durability, flexibility, and resistance to environmental factors. The blending systems are engineered to mix different resin components to achieve specific material characteristics required for various applications. These systems are integral to ensuring the consistency and quality of the final product, as they allow for precise control over the blending process. The market for these systems is driven by the increasing demand for high-performance materials in various industries, as well as advancements in technology that allow for more efficient and effective blending processes. As industries continue to innovate and develop new products, the need for advanced resin blending systems is expected to grow, making this market a critical component of the global manufacturing landscape.

4000 lbs./hour and Below, 4000 lbs./hour Above in the Global Resin Blending System Market:

In the Global Resin Blending System Market, the capacity of the systems is a significant factor that influences their application and demand. Systems with a capacity of 4000 lbs./hour and below are typically used in smaller-scale operations or for specialized applications where precision and flexibility are more critical than sheer volume. These systems are often favored by industries that require frequent changes in resin formulations or those that produce a wide variety of products in smaller batches. For instance, in the electronics industry, where specific resin formulations are needed for different components, a smaller capacity system allows for quick adjustments and efficient production without the need for large-scale operations. On the other hand, systems with a capacity of 4000 lbs./hour and above are designed for large-scale manufacturing processes where high volume and efficiency are paramount. These systems are commonly used in industries such as automotive and construction, where the demand for resin-based materials is substantial, and the production processes are continuous and high-speed. The ability to produce large quantities of blended resin quickly and consistently is crucial in these sectors to meet the high demand and maintain competitive production costs. The choice between these two capacity ranges depends largely on the specific needs of the industry and the scale of production required. Companies must carefully evaluate their production goals, the complexity of their resin formulations, and their overall manufacturing strategy to determine the most suitable blending system for their operations. As the market continues to evolve, advancements in technology are likely to enhance the capabilities of both small and large capacity systems, offering even greater flexibility and efficiency to manufacturers across various industries.

Plastics Manufacturing, Automotive Industry, Construction Materials, Electronics, Others in the Global Resin Blending System Market:

The Global Resin Blending System Market finds extensive usage across several key industries, each leveraging the unique properties of resins to enhance their products and processes. In plastics manufacturing, resin blending systems are essential for creating a wide range of plastic products with specific characteristics such as strength, flexibility, and resistance to heat and chemicals. These systems allow manufacturers to tailor the properties of their plastics to meet the demands of different applications, from packaging materials to consumer goods. In the automotive industry, resin blending systems are used to produce high-performance materials that contribute to the safety, efficiency, and aesthetics of vehicles. Resins are used in various automotive components, including interior parts, exterior panels, and under-the-hood applications, where their lightweight and durable properties are highly valued. The construction materials industry also relies heavily on resin blending systems to produce materials that offer enhanced durability, weather resistance, and aesthetic appeal. Resins are used in products such as coatings, adhesives, and composite materials, which are essential for modern construction projects. In the electronics industry, resin blending systems are used to create materials that provide insulation, protection, and structural support for electronic components. These materials are critical for ensuring the reliability and longevity of electronic devices in various environments. Beyond these industries, resin blending systems are also used in other sectors such as aerospace, healthcare, and consumer goods, where the unique properties of resins can be leveraged to create innovative products and solutions. The versatility and adaptability of resin blending systems make them an indispensable tool for manufacturers looking to enhance their product offerings and meet the evolving demands of their respective markets.

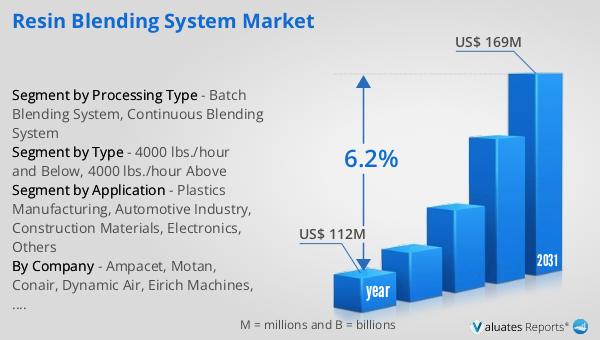

Global Resin Blending System Market Outlook:

The outlook for the Global Resin Blending System Market indicates a promising growth trajectory over the coming years. In 2024, the market was valued at approximately US$ 112 million, reflecting the significant demand for these systems across various industries. By 2031, the market is expected to expand to a revised size of US$ 169 million, driven by a compound annual growth rate (CAGR) of 6.2% during the forecast period. This growth is attributed to several factors, including the increasing demand for high-performance materials in industries such as automotive, construction, and electronics, as well as advancements in blending technology that enhance the efficiency and effectiveness of these systems. As manufacturers continue to innovate and develop new products, the need for advanced resin blending systems is expected to grow, making this market a critical component of the global manufacturing landscape. The ability of these systems to produce consistent, high-quality resin blends is essential for meeting the stringent requirements of modern manufacturing processes, and their versatility allows them to be used in a wide range of applications. As a result, the Global Resin Blending System Market is poised for continued growth and development, offering significant opportunities for manufacturers and suppliers in this dynamic and evolving industry.

| Report Metric | Details |

| Report Name | Resin Blending System Market |

| Accounted market size in year | US$ 112 million |

| Forecasted market size in 2031 | US$ 169 million |

| CAGR | 6.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Processing Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Ampacet, Motan, Conair, Dynamic Air, Eirich Machines, Process Control, Gruber Systems, Automation Ideas, Mconvey (Liansu), 2KM MUCOMAC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |