What is Global Metallocene High Density Polyethylene (mHDPE) Market?

Global Metallocene High Density Polyethylene (mHDPE) Market is a specialized segment within the broader polyethylene market, characterized by its unique properties and applications. Metallocene catalysts are used in the production of mHDPE, which results in a polymer with enhanced performance characteristics compared to conventional high-density polyethylene (HDPE). These characteristics include improved toughness, clarity, and processability, making mHDPE a preferred choice for various industrial applications. The global market for mHDPE is driven by its increasing demand in sectors such as packaging, automotive, and construction, where its superior properties offer significant advantages. The versatility of mHDPE allows it to be used in a wide range of products, from films and sheets to pipes and containers. As industries continue to seek materials that offer both performance and sustainability, mHDPE stands out due to its recyclability and reduced environmental impact. The market is also influenced by technological advancements in polymer production, which enhance the efficiency and quality of mHDPE products. Overall, the global mHDPE market is poised for growth as it continues to meet the evolving needs of various industries.

Profile Extrusion, Injection Molding, Film and Sheet Extrusion, Blow Molding, Others in the Global Metallocene High Density Polyethylene (mHDPE) Market:

Profile extrusion, injection molding, film and sheet extrusion, blow molding, and other processes are integral to the Global Metallocene High Density Polyethylene (mHDPE) Market, each offering unique advantages and applications. Profile extrusion involves shaping mHDPE into continuous profiles, such as pipes and tubing, which are essential in construction and plumbing industries due to their durability and resistance to environmental stress. Injection molding, on the other hand, is a versatile process used to produce complex and detailed parts by injecting molten mHDPE into molds. This method is widely used in manufacturing automotive components, consumer goods, and packaging materials, where precision and strength are crucial. Film and sheet extrusion is another significant process, where mHDPE is extruded into thin films or sheets, commonly used in packaging, agriculture, and industrial applications. These films offer excellent barrier properties, flexibility, and clarity, making them ideal for food packaging and protective coverings. Blow molding is a process used to create hollow plastic parts, such as bottles and containers, by inflating a heated mHDPE parison inside a mold. This technique is favored in the packaging industry for producing lightweight and durable containers. Other processes in the mHDPE market include rotational molding and thermoforming, which are used for specialized applications requiring specific shapes and properties. Rotational molding involves heating mHDPE in a mold that rotates on multiple axes, creating large, hollow products like tanks and playground equipment. Thermoforming, on the other hand, involves heating mHDPE sheets and forming them over molds to create products like trays and clamshell packaging. Each of these processes leverages the unique properties of mHDPE, such as its strength, chemical resistance, and ease of processing, to produce high-quality products for various industries. As the demand for sustainable and high-performance materials grows, these manufacturing processes will continue to play a crucial role in the expansion of the global mHDPE market.

Caps & Closures, Geomembranes, Tapes, Cross-Linked Polyethylene, Sheet and films, Pipes & Tubes, Packaging, Others in the Global Metallocene High Density Polyethylene (mHDPE) Market:

The usage of Global Metallocene High Density Polyethylene (mHDPE) Market spans a wide range of applications, including caps and closures, geomembranes, tapes, cross-linked polyethylene, sheets and films, pipes and tubes, packaging, and others. In the caps and closures segment, mHDPE is valued for its excellent sealing properties, chemical resistance, and durability, making it ideal for use in beverage, pharmaceutical, and personal care products. Geomembranes made from mHDPE are used in environmental and civil engineering projects for lining landfills, ponds, and canals due to their impermeability and resistance to UV radiation and chemicals. Tapes manufactured from mHDPE offer high tensile strength and adhesion, making them suitable for industrial and packaging applications. Cross-linked polyethylene, a derivative of mHDPE, is used in plumbing and heating systems for its flexibility, heat resistance, and long-term reliability. Sheets and films made from mHDPE are widely used in packaging, agriculture, and construction for their clarity, toughness, and barrier properties. In the pipes and tubes segment, mHDPE is favored for its strength, corrosion resistance, and ease of installation, making it a preferred choice for water supply, gas distribution, and sewage systems. The packaging industry extensively uses mHDPE for producing containers, bottles, and flexible packaging solutions due to its lightweight, durability, and recyclability. Other applications of mHDPE include automotive components, toys, and household goods, where its superior mechanical properties and ease of processing offer significant advantages. As industries continue to prioritize sustainability and performance, the usage of mHDPE in these diverse applications is expected to grow, driven by its ability to meet the demanding requirements of modern manufacturing and consumer needs.

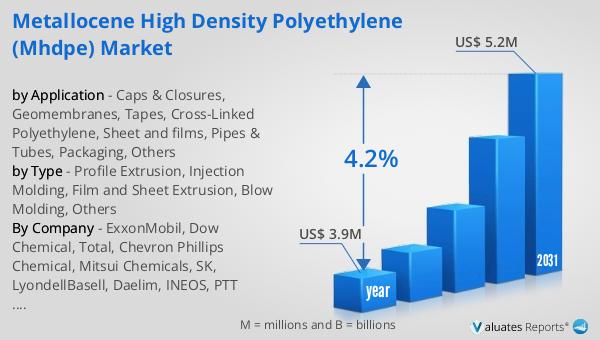

Global Metallocene High Density Polyethylene (mHDPE) Market Outlook:

The global market for Metallocene High Density Polyethylene (mHDPE) was valued at approximately $3.9 million in 2024, with projections indicating a growth to around $5.2 million by 2031. This growth represents a compound annual growth rate (CAGR) of 4.2% over the forecast period. This upward trend is indicative of the increasing demand for mHDPE across various industries due to its superior properties and versatility. The market's expansion is driven by the need for high-performance materials that offer both durability and sustainability. As industries such as packaging, automotive, and construction continue to evolve, the demand for materials like mHDPE that can meet stringent performance and environmental standards is expected to rise. The projected growth in the mHDPE market reflects the material's ability to adapt to changing industry needs and its potential to replace traditional materials in various applications. With advancements in polymer technology and an increasing focus on sustainable practices, the mHDPE market is well-positioned to capitalize on these trends and continue its growth trajectory. The market outlook suggests a positive future for mHDPE, as it continues to play a crucial role in the development of innovative and sustainable solutions across multiple sectors.

| Report Metric | Details |

| Report Name | Metallocene High Density Polyethylene (mHDPE) Market |

| Accounted market size in year | US$ 3.9 million |

| Forecasted market size in 2031 | US$ 5.2 million |

| CAGR | 4.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ExxonMobil, Dow Chemical, Total, Chevron Phillips Chemical, Mitsui Chemicals, SK, LyondellBasell, Daelim, INEOS, PTT Global, Qilu Petrochemical, Dushanzi Petrochemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |