What is Global Zinc Rich Container Coating Market?

The Global Zinc Rich Container Coating Market is a specialized segment within the broader coatings industry, focusing on the application of zinc-rich coatings to containers used in various industries. These coatings are primarily used to protect metal surfaces from corrosion, which is a significant concern for containers exposed to harsh environmental conditions. Zinc-rich coatings are formulated with a high percentage of zinc dust, which provides cathodic protection to the underlying metal. This means that the zinc acts as a sacrificial anode, corroding in place of the metal it protects. The market for these coatings is driven by the need for durable and long-lasting protection for containers, which are often used in shipping, storage, and transportation. The demand for zinc-rich coatings is influenced by factors such as the growth of international trade, the expansion of the shipping industry, and the increasing need for efficient and reliable storage solutions. Additionally, environmental regulations and the push for sustainable practices have led to the development of more eco-friendly coating formulations, further impacting the market dynamics. Overall, the Global Zinc Rich Container Coating Market plays a crucial role in ensuring the longevity and performance of containers across various sectors.

Epoxy Zinc-rich Primer, Inorganic Zinc-rich Primer in the Global Zinc Rich Container Coating Market:

Epoxy Zinc-rich Primer and Inorganic Zinc-rich Primer are two primary types of coatings used in the Global Zinc Rich Container Coating Market, each offering distinct advantages and applications. Epoxy Zinc-rich Primers are formulated with epoxy resins and a high concentration of zinc dust, providing excellent adhesion and corrosion resistance. These primers are particularly effective in environments where containers are exposed to moisture, chemicals, and mechanical wear. The epoxy base offers a robust barrier against environmental factors, making it ideal for use in marine and industrial settings. Additionally, epoxy zinc-rich primers are known for their quick drying times and ease of application, which can be advantageous in large-scale container coating projects. On the other hand, Inorganic Zinc-rich Primers are based on silicate binders and also contain a high percentage of zinc dust. These primers offer superior heat resistance and are often used in high-temperature environments. The inorganic nature of these primers provides excellent durability and long-term protection against corrosion, even in the most challenging conditions. Inorganic zinc-rich primers are particularly suitable for containers that are exposed to extreme weather conditions or are used in offshore applications. Both types of primers play a vital role in the Global Zinc Rich Container Coating Market, catering to different needs and requirements based on the specific conditions and environments in which the containers are used. The choice between epoxy and inorganic zinc-rich primers often depends on factors such as the intended use of the container, the environmental conditions it will face, and the desired longevity of the coating. In recent years, advancements in coating technology have led to the development of hybrid formulations that combine the benefits of both epoxy and inorganic zinc-rich primers, offering enhanced performance and versatility. These innovations are driving growth in the market, as manufacturers seek to provide solutions that meet the evolving demands of the industry. Furthermore, the increasing focus on sustainability and environmental compliance has prompted the development of low-VOC (volatile organic compounds) and eco-friendly zinc-rich coatings, which are gaining popularity among environmentally conscious consumers and businesses. As the Global Zinc Rich Container Coating Market continues to evolve, the demand for high-performance primers that offer reliable protection and meet regulatory standards is expected to remain strong. The ongoing research and development efforts in this field are likely to result in further innovations and improvements in coating formulations, ensuring that containers remain protected and functional in a wide range of applications and environments.

Standard Container, High Cube Container, Reefer Container, Double Door Container, Open Top Container in the Global Zinc Rich Container Coating Market:

The Global Zinc Rich Container Coating Market finds its application across various types of containers, each serving specific purposes and requiring tailored protection solutions. Standard Containers are the most common type used in the shipping industry, designed to transport a wide range of goods. These containers require robust coatings to withstand the rigors of sea transport, including exposure to saltwater, humidity, and temperature fluctuations. Zinc-rich coatings provide the necessary protection against corrosion, ensuring the structural integrity and longevity of these containers. High Cube Containers, which offer additional height compared to standard containers, are used for transporting voluminous goods. The increased surface area of these containers necessitates effective coating solutions to prevent corrosion and maintain their usability over time. Zinc-rich coatings are ideal for this purpose, offering a durable protective layer that can withstand the challenges of long-distance transport. Reefer Containers, or refrigerated containers, are used to transport perishable goods that require temperature control. The internal and external surfaces of these containers are exposed to varying temperatures and humidity levels, making them susceptible to corrosion. Zinc-rich coatings are essential in protecting these containers, ensuring that they remain functional and efficient in preserving the quality of the goods they carry. Double Door Containers, which feature doors on both ends, provide easy access to goods and are often used in logistics and distribution. The design of these containers requires coatings that can protect the additional door surfaces from corrosion and wear. Zinc-rich coatings offer the necessary protection, ensuring that the containers remain operational and secure. Open Top Containers, used for transporting oversized cargo, have an open roof covered by a tarpaulin. The exposure to the elements makes these containers particularly vulnerable to corrosion, necessitating the use of high-performance coatings. Zinc-rich coatings provide the required protection, ensuring that the containers can safely transport goods without compromising their structural integrity. In all these applications, the Global Zinc Rich Container Coating Market plays a crucial role in ensuring that containers remain durable, reliable, and capable of withstanding the challenges of transport and storage. The choice of coating depends on factors such as the type of container, the goods being transported, and the environmental conditions they will face. As the demand for efficient and sustainable transport solutions continues to grow, the market for zinc-rich container coatings is expected to expand, driven by the need for high-quality protection and performance.

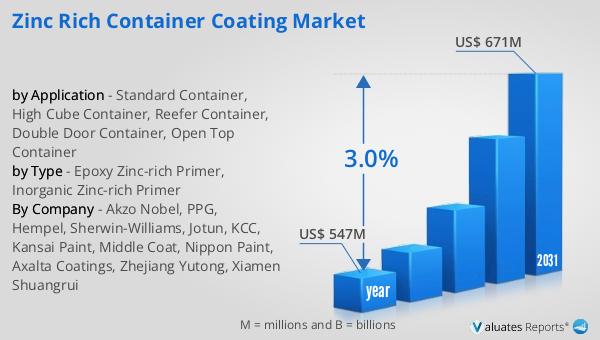

Global Zinc Rich Container Coating Market Outlook:

In 2024, the Global Zinc Rich Container Coating Market was valued at approximately $547 million. This market is anticipated to grow steadily, reaching an estimated value of $671 million by 2031. This growth represents a compound annual growth rate (CAGR) of 3.0% over the forecast period. The steady increase in market size reflects the rising demand for zinc-rich coatings, driven by the need for effective corrosion protection in various container applications. As industries continue to expand and global trade increases, the demand for durable and reliable container coatings is expected to rise. Zinc-rich coatings offer a cost-effective solution for protecting containers from the harsh environmental conditions they often face, such as exposure to saltwater, humidity, and temperature fluctuations. The market's growth is also influenced by advancements in coating technology, which have led to the development of more efficient and environmentally friendly formulations. These innovations are helping to meet the evolving needs of the industry, ensuring that containers remain protected and functional in a wide range of applications. As the market continues to evolve, the focus on sustainability and regulatory compliance is expected to drive further growth, with manufacturers seeking to provide high-performance coatings that meet the demands of environmentally conscious consumers and businesses.

| Report Metric | Details |

| Report Name | Zinc Rich Container Coating Market |

| Accounted market size in year | US$ 547 million |

| Forecasted market size in 2031 | US$ 671 million |

| CAGR | 3.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Akzo Nobel, PPG, Hempel, Sherwin-Williams, Jotun, KCC, Kansai Paint, Middle Coat, Nippon Paint, Axalta Coatings, Zhejiang Yutong, Xiamen Shuangrui |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |