What is Global High Temperature Electrostatic Chuck Bonding Adhesive Market?

The Global High Temperature Electrostatic Chuck Bonding Adhesive Market is a specialized segment within the broader adhesives industry, focusing on products that can withstand extreme temperatures while maintaining strong bonding capabilities. These adhesives are crucial in the manufacturing of electrostatic chucks, which are devices used to hold semiconductor wafers during processing. The demand for high temperature electrostatic chuck bonding adhesives is driven by the semiconductor industry's need for materials that can endure the rigorous conditions of wafer processing, including high temperatures and vacuum environments. These adhesives must provide excellent thermal stability, electrical insulation, and mechanical strength to ensure the reliability and efficiency of the chucks. As the semiconductor industry continues to grow and evolve, the demand for advanced materials like high temperature electrostatic chuck bonding adhesives is expected to increase, driven by the need for more efficient and reliable manufacturing processes. This market is characterized by ongoing research and development efforts aimed at improving adhesive formulations to meet the ever-changing requirements of semiconductor manufacturing. Companies operating in this market are focused on developing innovative solutions that offer enhanced performance, sustainability, and cost-effectiveness to meet the needs of their customers.

Silicon-based Polymeric Material, Others in the Global High Temperature Electrostatic Chuck Bonding Adhesive Market:

Silicon-based polymeric materials are a key component in the Global High Temperature Electrostatic Chuck Bonding Adhesive Market. These materials are known for their excellent thermal stability, electrical insulation properties, and mechanical strength, making them ideal for use in high temperature applications. Silicon-based adhesives are often used in the manufacturing of electrostatic chucks due to their ability to withstand the extreme conditions of semiconductor processing, including high temperatures and vacuum environments. These adhesives provide a strong bond between the chuck and the wafer, ensuring that the wafer remains securely in place during processing. In addition to their thermal and mechanical properties, silicon-based adhesives also offer excellent chemical resistance, which is important in semiconductor manufacturing where harsh chemicals are often used. This resistance helps to ensure the longevity and reliability of the adhesive bond, reducing the risk of failure and improving the overall efficiency of the manufacturing process. The development of silicon-based polymeric materials for use in high temperature electrostatic chuck bonding adhesives is an area of ongoing research and development. Companies in this market are focused on improving the performance of these materials to meet the evolving needs of the semiconductor industry. This includes efforts to enhance the thermal stability, electrical insulation properties, and mechanical strength of silicon-based adhesives, as well as improving their chemical resistance and environmental sustainability. In addition to silicon-based materials, there are other types of adhesives used in the Global High Temperature Electrostatic Chuck Bonding Adhesive Market. These include epoxy-based adhesives, which are known for their strong bonding capabilities and excellent thermal and chemical resistance. Epoxy-based adhesives are often used in applications where a strong, durable bond is required, and they are capable of withstanding the extreme conditions of semiconductor processing. Another type of adhesive used in this market is polyimide-based adhesives. These materials are known for their excellent thermal stability and electrical insulation properties, making them ideal for use in high temperature applications. Polyimide-based adhesives are often used in the manufacturing of electrostatic chucks due to their ability to withstand the extreme conditions of semiconductor processing. In addition to their thermal and electrical properties, polyimide-based adhesives also offer excellent chemical resistance, which is important in semiconductor manufacturing where harsh chemicals are often used. The development of polyimide-based adhesives for use in high temperature electrostatic chuck bonding applications is an area of ongoing research and development. Companies in this market are focused on improving the performance of these materials to meet the evolving needs of the semiconductor industry. This includes efforts to enhance the thermal stability, electrical insulation properties, and mechanical strength of polyimide-based adhesives, as well as improving their chemical resistance and environmental sustainability. Overall, the Global High Temperature Electrostatic Chuck Bonding Adhesive Market is characterized by a diverse range of materials and formulations, each offering unique properties and benefits. Companies operating in this market are focused on developing innovative solutions that meet the specific needs of their customers, while also addressing broader industry trends such as sustainability and cost-effectiveness. As the semiconductor industry continues to grow and evolve, the demand for advanced materials like high temperature electrostatic chuck bonding adhesives is expected to increase, driven by the need for more efficient and reliable manufacturing processes.

Ceramic Electrostatic Chuck, Polyimide Electrostatic Chuck, Others in the Global High Temperature Electrostatic Chuck Bonding Adhesive Market:

The usage of Global High Temperature Electrostatic Chuck Bonding Adhesive Market in areas such as Ceramic Electrostatic Chuck, Polyimide Electrostatic Chuck, and others is crucial for the semiconductor manufacturing process. Ceramic electrostatic chucks are widely used in the semiconductor industry due to their excellent thermal and electrical properties. These chucks require adhesives that can withstand high temperatures and provide strong bonding capabilities to ensure the wafer remains securely in place during processing. High temperature electrostatic chuck bonding adhesives used in ceramic chucks must offer excellent thermal stability, electrical insulation, and mechanical strength to ensure the reliability and efficiency of the chuck. In addition to their thermal and mechanical properties, these adhesives must also provide excellent chemical resistance to withstand the harsh chemicals used in semiconductor manufacturing. Polyimide electrostatic chucks are another important application area for high temperature electrostatic chuck bonding adhesives. Polyimide chucks are known for their excellent thermal stability and electrical insulation properties, making them ideal for use in high temperature applications. The adhesives used in polyimide chucks must provide a strong bond between the chuck and the wafer, ensuring that the wafer remains securely in place during processing. These adhesives must also offer excellent chemical resistance to withstand the harsh chemicals used in semiconductor manufacturing. The development of high temperature electrostatic chuck bonding adhesives for use in polyimide chucks is an area of ongoing research and development. Companies in this market are focused on improving the performance of these adhesives to meet the evolving needs of the semiconductor industry. This includes efforts to enhance the thermal stability, electrical insulation properties, and mechanical strength of the adhesives, as well as improving their chemical resistance and environmental sustainability. In addition to ceramic and polyimide chucks, there are other types of electrostatic chucks that require high temperature bonding adhesives. These include chucks made from materials such as aluminum nitride and silicon carbide, which offer unique properties and benefits for specific applications. The adhesives used in these chucks must provide strong bonding capabilities and excellent thermal and electrical properties to ensure the reliability and efficiency of the chuck. Overall, the usage of Global High Temperature Electrostatic Chuck Bonding Adhesive Market in areas such as Ceramic Electrostatic Chuck, Polyimide Electrostatic Chuck, and others is critical for the semiconductor manufacturing process. These adhesives play a vital role in ensuring the reliability and efficiency of electrostatic chucks, which are essential for holding semiconductor wafers during processing. As the semiconductor industry continues to grow and evolve, the demand for advanced materials like high temperature electrostatic chuck bonding adhesives is expected to increase, driven by the need for more efficient and reliable manufacturing processes.

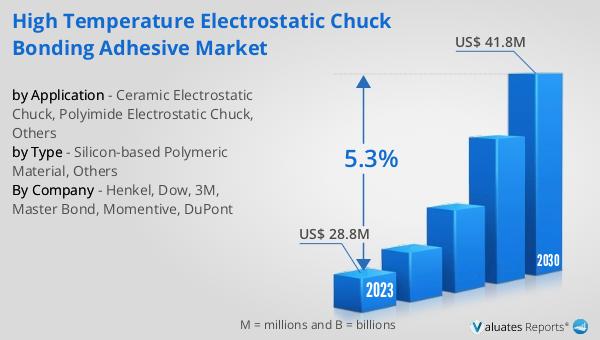

Global High Temperature Electrostatic Chuck Bonding Adhesive Market Outlook:

The outlook for the global High Temperature Electrostatic Chuck Bonding Adhesive market indicates a promising growth trajectory. The market is anticipated to expand from $30.7 million in 2024 to $43.7 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.3% from 2025 to 2031. This growth is largely driven by the critical product segments and the diverse range of end-use applications that these adhesives cater to. The semiconductor industry, which is a major consumer of these adhesives, continues to evolve, demanding more advanced materials that can withstand the rigorous conditions of semiconductor processing. However, the market is not without its challenges. The evolving U.S. tariff policies have introduced a degree of volatility in trade costs, which in turn affects the supply chain dynamics. This uncertainty can pose challenges for manufacturers and suppliers in the market, as they navigate the complexities of international trade and the associated costs. Despite these challenges, the market's growth prospects remain strong, driven by the increasing demand for high-performance adhesives in the semiconductor industry. Companies operating in this market are focused on developing innovative solutions that meet the specific needs of their customers, while also addressing broader industry trends such as sustainability and cost-effectiveness. As the market continues to grow, companies will need to remain agile and responsive to the changing landscape, leveraging their expertise and capabilities to capitalize on the opportunities presented by this dynamic market.

| Report Metric | Details |

| Report Name | High Temperature Electrostatic Chuck Bonding Adhesive Market |

| Accounted market size in 2024 | US$ 30.7 million |

| Forecasted market size in 2031 | US$ 43.7 million |

| CAGR | 5.3% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Henkel, Dow, 3M, Master Bond, Momentive, DuPont |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |