What is Global Industrial Shot Blasting Robots Market?

The Global Industrial Shot Blasting Robots Market refers to the sector that focuses on the production and utilization of robots specifically designed for shot blasting processes. Shot blasting is a method used to clean, strengthen, or polish metal surfaces by propelling abrasive materials at high speeds. These robots are employed in various industries to automate the shot blasting process, enhancing efficiency, precision, and safety. The market for these robots is expanding due to the increasing demand for automation in manufacturing processes, which helps in reducing labor costs and improving product quality. Additionally, the adoption of these robots is driven by the need for consistent and high-quality surface finishes, especially in industries like automotive, aerospace, and construction. As industries continue to seek ways to optimize their operations and reduce manual labor, the demand for industrial shot blasting robots is expected to grow, making it a significant area of interest for manufacturers and investors alike. The market is characterized by technological advancements, with companies investing in research and development to produce more efficient and versatile robots that can cater to a wide range of industrial applications.

Wireless Remote Control, Manual Button in the Global Industrial Shot Blasting Robots Market:

In the realm of the Global Industrial Shot Blasting Robots Market, the integration of wireless remote control and manual button systems plays a pivotal role in enhancing operational efficiency and user convenience. Wireless remote control systems allow operators to manage shot blasting robots from a distance, providing flexibility and safety, especially in hazardous environments. This technology enables operators to control the robots without being in close proximity, reducing the risk of exposure to dust and debris generated during the blasting process. The convenience of wireless control also allows for quick adjustments and real-time monitoring, ensuring that the blasting process is carried out with precision and minimal downtime. On the other hand, manual button systems offer a more traditional approach to controlling shot blasting robots. These systems are often preferred in environments where wireless technology may be unreliable or where operators are accustomed to hands-on control. Manual buttons provide direct and immediate feedback, allowing operators to make precise adjustments to the robot's operations. This method is particularly useful in scenarios where intricate control is required, such as in detailed surface finishing tasks. Both wireless remote control and manual button systems have their unique advantages and are often used in conjunction to provide a comprehensive control solution for industrial shot blasting robots. The choice between these systems depends on various factors, including the specific requirements of the blasting process, the working environment, and the operator's preference. As technology continues to evolve, the integration of advanced control systems in shot blasting robots is expected to become more sophisticated, offering enhanced functionality and user experience. This evolution is likely to include features such as touch-screen interfaces, voice control, and even artificial intelligence, further streamlining the operation of shot blasting robots and expanding their applicability across different industries. The ongoing development of control systems in the Global Industrial Shot Blasting Robots Market underscores the importance of adaptability and innovation in meeting the diverse needs of modern manufacturing processes. As industries continue to embrace automation, the demand for versatile and user-friendly control systems is expected to rise, driving further advancements in this field. Ultimately, the integration of wireless remote control and manual button systems in shot blasting robots represents a significant step forward in the quest for efficient, safe, and precise industrial operations.

Machinery Manufacturing, Shipbuilding Engineering, Construction, Others in the Global Industrial Shot Blasting Robots Market:

The Global Industrial Shot Blasting Robots Market finds extensive application across various sectors, including machinery manufacturing, shipbuilding engineering, construction, and others. In machinery manufacturing, shot blasting robots are used to clean and prepare metal surfaces before painting or coating. This process is crucial for ensuring that the final product has a smooth and durable finish. The use of robots in this sector enhances productivity by automating repetitive tasks, reducing the need for manual labor, and minimizing the risk of human error. In shipbuilding engineering, shot blasting robots play a vital role in preparing large metal surfaces for welding and painting. The harsh marine environment demands high-quality surface finishes to prevent corrosion and extend the lifespan of ships. Robots provide consistent and precise blasting, ensuring that every inch of the surface is adequately prepared. This not only improves the quality of the final product but also reduces the time and cost associated with manual blasting. In the construction industry, shot blasting robots are used to clean and prepare concrete surfaces, remove old paint, and create a rough texture for better adhesion of new coatings. The automation of these tasks improves efficiency and safety, as workers are not exposed to dust and debris. Additionally, robots can work continuously without fatigue, ensuring that large areas are covered quickly and effectively. Beyond these sectors, shot blasting robots are also used in industries such as aerospace, automotive, and energy. In aerospace, they are employed to clean and strengthen aircraft components, ensuring that they meet stringent safety and performance standards. In the automotive industry, robots are used to prepare car bodies and parts for painting, enhancing the quality and durability of the finish. In the energy sector, shot blasting robots are used to clean and maintain equipment such as pipelines and wind turbines, ensuring their optimal performance and longevity. The versatility and efficiency of shot blasting robots make them an invaluable asset across various industries, driving their adoption and growth in the global market.

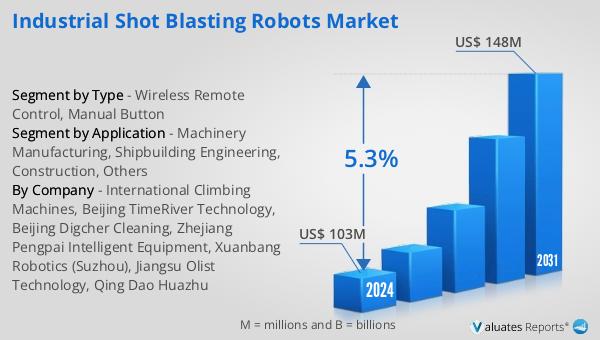

Global Industrial Shot Blasting Robots Market Outlook:

The outlook for the Global Industrial Shot Blasting Robots Market indicates a promising growth trajectory, with projections suggesting an increase from US$ 103 million in 2024 to US$ 148 million by 2031. This growth, at a compound annual growth rate (CAGR) of 5.3% from 2025 to 2031, is fueled by the expansion of critical product segments and the diversification of end-use applications. As industries continue to seek automation solutions to enhance efficiency and reduce costs, the demand for shot blasting robots is expected to rise. These robots offer significant advantages in terms of precision, consistency, and safety, making them an attractive option for various industrial applications. However, the market is not without its challenges. Evolving U.S. tariff policies introduce an element of trade-cost volatility and supply-chain uncertainty, which could impact the market dynamics. Companies operating in this space need to navigate these challenges carefully, balancing the need for innovation and expansion with the realities of a fluctuating trade environment. Despite these challenges, the overall outlook for the Global Industrial Shot Blasting Robots Market remains positive, driven by the increasing adoption of automation technologies and the continuous development of advanced robotic solutions. As industries continue to evolve and adapt to changing market conditions, the role of shot blasting robots is expected to become even more integral to modern manufacturing processes.

| Report Metric | Details |

| Report Name | Industrial Shot Blasting Robots Market |

| Accounted market size in 2024 | US$ 103 million |

| Forecasted market size in 2031 | US$ 148 million |

| CAGR | 5.3% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | International Climbing Machines, Beijing TimeRiver Technology, Beijing Digcher Cleaning, Zhejiang Pengpai Intelligent Equipment, Xuanbang Robotics (Suzhou), Jiangsu Olist Technology, Qing Dao Huazhu |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |