What is Global Wheel Protective Coating Market?

The Global Wheel Protective Coating Market is a specialized segment within the automotive industry that focuses on providing protective coatings for vehicle wheels. These coatings are designed to enhance the durability, appearance, and longevity of wheels by protecting them from environmental factors such as corrosion, abrasion, and chemical exposure. The market encompasses a variety of coating types, including powder coatings and liquid coatings, each offering distinct advantages in terms of application and performance. The demand for wheel protective coatings is driven by the increasing production of vehicles worldwide, coupled with a growing consumer preference for aesthetically pleasing and long-lasting wheel finishes. Additionally, advancements in coating technologies have led to the development of more efficient and environmentally friendly products, further propelling market growth. As vehicle manufacturers and consumers alike seek to maintain the quality and appearance of wheels, the Global Wheel Protective Coating Market continues to expand, offering innovative solutions to meet the evolving needs of the automotive industry. The market's growth is also supported by the rising awareness of the benefits of protective coatings, such as reduced maintenance costs and enhanced vehicle resale value, making it an essential component of modern automotive care.

Powder Coating, Liquid Coating in the Global Wheel Protective Coating Market:

Powder coating and liquid coating are two primary methods used in the Global Wheel Protective Coating Market, each offering unique benefits and applications. Powder coating is a dry finishing process that involves applying a free-flowing, dry powder to the wheel surface. This method is known for its durability, resistance to chipping, scratching, and fading, making it an ideal choice for wheels that are exposed to harsh environmental conditions. The powder is typically applied electrostatically and then cured under heat, allowing it to form a hard, protective layer. One of the key advantages of powder coating is its environmental friendliness, as it contains no solvents and releases negligible amounts of volatile organic compounds (VOCs) into the atmosphere. This makes it a popular choice among manufacturers looking to reduce their environmental footprint. Additionally, powder coatings offer a wide range of color options and finishes, allowing for customization to meet specific aesthetic preferences. On the other hand, liquid coating involves the application of a liquid paint to the wheel surface, which is then cured to form a protective layer. Liquid coatings are known for their versatility and ability to provide a smooth, high-gloss finish. They are particularly effective in achieving intricate designs and detailed finishes, making them a preferred choice for high-end and luxury vehicles. Liquid coatings also offer excellent adhesion properties, ensuring long-lasting protection against corrosion and wear. However, they may contain solvents and VOCs, which can have environmental implications. Despite this, advancements in liquid coating technologies have led to the development of low-VOC and water-based formulations, addressing environmental concerns while maintaining performance standards. Both powder and liquid coatings play a crucial role in the Global Wheel Protective Coating Market, catering to diverse consumer needs and preferences. Manufacturers often choose between these methods based on factors such as cost, desired finish, and environmental considerations. As the market continues to evolve, innovations in coating technologies are expected to further enhance the performance and sustainability of both powder and liquid coatings, ensuring their continued relevance in the automotive industry. The choice between powder and liquid coatings ultimately depends on the specific requirements of the application, with each offering distinct advantages that contribute to the overall protection and aesthetic appeal of vehicle wheels.

Commercial Vehicle, Passenger Vehicle in the Global Wheel Protective Coating Market:

The Global Wheel Protective Coating Market finds significant application in both commercial and passenger vehicles, each with distinct requirements and benefits. In the realm of commercial vehicles, wheel protective coatings are essential for maintaining the durability and performance of wheels that are subjected to heavy loads and frequent use. Commercial vehicles, such as trucks and buses, often operate in challenging environments, where wheels are exposed to dirt, debris, and corrosive substances. Protective coatings help to prevent corrosion and wear, thereby extending the lifespan of the wheels and reducing maintenance costs. The use of durable coatings also enhances the safety and reliability of commercial vehicles, as well-maintained wheels are crucial for optimal performance and fuel efficiency. Additionally, the aesthetic appeal of coated wheels can contribute to the professional image of commercial fleets, which is important for businesses that rely on their vehicles for branding and customer perception. In passenger vehicles, wheel protective coatings serve both functional and aesthetic purposes. Consumers are increasingly seeking vehicles with visually appealing and long-lasting finishes, and wheel coatings play a vital role in achieving this. Protective coatings help to preserve the appearance of wheels by preventing damage from road debris, brake dust, and environmental factors. This not only enhances the overall look of the vehicle but also contributes to its resale value. Furthermore, the use of advanced coatings can improve the ease of cleaning and maintenance, as coated wheels are less likely to accumulate dirt and grime. In both commercial and passenger vehicles, the choice of coating type—whether powder or liquid—depends on factors such as cost, desired finish, and environmental considerations. As the automotive industry continues to prioritize sustainability and performance, the demand for innovative and eco-friendly wheel protective coatings is expected to grow. The Global Wheel Protective Coating Market plays a crucial role in meeting the diverse needs of vehicle manufacturers and consumers, offering solutions that enhance the durability, appearance, and value of both commercial and passenger vehicles.

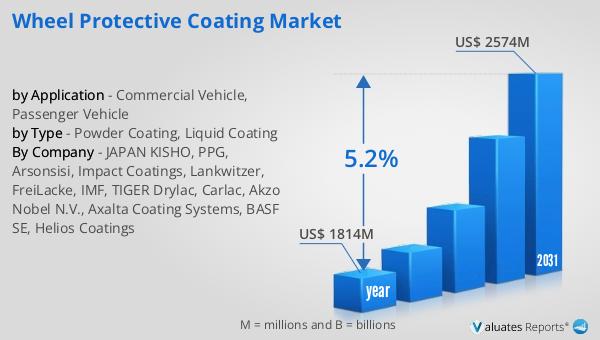

Global Wheel Protective Coating Market Outlook:

In 2024, the global market for Wheel Protective Coating was valued at approximately $1,814 million. This market is anticipated to grow steadily, reaching an estimated value of $2,574 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.2% over the forecast period. The steady increase in market size reflects the rising demand for protective coatings in the automotive industry, driven by factors such as the growing production of vehicles and the increasing consumer preference for durable and aesthetically pleasing wheel finishes. As vehicle manufacturers continue to seek innovative solutions to enhance the performance and appearance of wheels, the market for wheel protective coatings is expected to expand. The projected growth also underscores the importance of advancements in coating technologies, which are enabling the development of more efficient and environmentally friendly products. These innovations are crucial in addressing the evolving needs of the automotive industry, as well as meeting the increasing regulatory requirements for sustainability and environmental protection. The Global Wheel Protective Coating Market is poised for continued growth, offering significant opportunities for manufacturers and consumers alike to benefit from enhanced wheel protection and aesthetics.

| Report Metric | Details |

| Report Name | Wheel Protective Coating Market |

| Accounted market size in year | US$ 1814 million |

| Forecasted market size in 2031 | US$ 2574 million |

| CAGR | 5.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | JAPAN KISHO, PPG, Arsonsisi, Impact Coatings, Lankwitzer, FreiLacke, IMF, TIGER Drylac, Carlac, Akzo Nobel N.V., Axalta Coating Systems, BASF SE, Helios Coatings |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |