What is Global Glass Forming Production Lines Market?

The Global Glass Forming Production Lines Market refers to the industry involved in the manufacturing and assembly of machinery and equipment used to produce glass products. This market encompasses a wide range of production lines designed to form glass into various shapes and sizes, catering to diverse industries such as construction, automotive, consumer goods, and more. These production lines are essential for transforming raw glass materials into finished products, ensuring precision, efficiency, and quality in the manufacturing process. The market is characterized by technological advancements, which have led to the development of sophisticated machinery capable of producing complex glass forms with high accuracy. As industries continue to demand innovative glass solutions, the Global Glass Forming Production Lines Market plays a crucial role in meeting these needs by providing the necessary infrastructure and technology. The market's growth is driven by increasing demand for glass products across various sectors, coupled with the need for energy-efficient and sustainable production methods. As a result, manufacturers are investing in advanced production lines to enhance their capabilities and meet the evolving requirements of their customers.

Press Lines, Spinning Lines, Blow Blow Lines, Press Blow Lines, Tubing Lines, Flat Glass Lines, Others in the Global Glass Forming Production Lines Market:

Press Lines, Spinning Lines, Blow Blow Lines, Press Blow Lines, Tubing Lines, Flat Glass Lines, and other types of production lines are integral components of the Global Glass Forming Production Lines Market. Each type of line serves a specific purpose and is designed to produce particular glass products. Press Lines are used to shape glass by applying pressure, often employed in the production of glass containers and tableware. These lines are known for their ability to produce high-quality, uniform products with precise dimensions. Spinning Lines, on the other hand, utilize centrifugal force to form glass into desired shapes, commonly used in the production of glass fibers and other specialized products. Blow Blow Lines are designed for the production of hollow glass items, such as bottles and jars, by blowing air into molten glass to shape it. This method is highly efficient and allows for the production of large quantities of uniform products. Press Blow Lines combine the techniques of pressing and blowing to create glass containers with intricate designs and shapes. Tubing Lines are specialized for producing glass tubes, which are used in various applications, including laboratory equipment and lighting. These lines are designed to ensure precision and consistency in the production of glass tubes. Flat Glass Lines are used to produce flat glass sheets, which are essential in the construction and automotive industries. These lines are equipped with advanced technology to ensure the production of high-quality, defect-free glass sheets. Other types of production lines in the market cater to niche applications, offering customized solutions for specific glass products. The diversity of production lines in the Global Glass Forming Production Lines Market reflects the wide range of applications and industries that rely on glass products. As technology continues to advance, these production lines are becoming more efficient and capable of producing increasingly complex glass forms. Manufacturers are continually innovating to meet the demands of their customers, ensuring that the market remains dynamic and competitive.

Tableware and Kitchenware, Technical Glass, Others in the Global Glass Forming Production Lines Market:

The Global Glass Forming Production Lines Market finds extensive usage in various areas, including Tableware and Kitchenware, Technical Glass, and other applications. In the realm of Tableware and Kitchenware, glass forming production lines are crucial for manufacturing a wide range of products such as glasses, plates, bowls, and other kitchen essentials. These production lines ensure that the glassware is not only aesthetically pleasing but also durable and functional. The precision and efficiency of these lines allow manufacturers to produce high-quality products that meet the demands of consumers for both everyday use and special occasions. In the Technical Glass sector, glass forming production lines are used to create specialized glass products for industries such as electronics, telecommunications, and healthcare. These products often require high levels of precision and quality, as they are used in critical applications such as optical lenses, display screens, and medical devices. The advanced technology and capabilities of glass forming production lines enable manufacturers to produce technical glass products that meet stringent industry standards. Additionally, the market serves other areas, including the automotive and construction industries, where glass is used for windows, windshields, and architectural elements. The versatility of glass forming production lines allows manufacturers to produce a wide range of products tailored to the specific needs of these industries. As demand for innovative and sustainable glass solutions continues to grow, the Global Glass Forming Production Lines Market plays a vital role in supporting the production of high-quality glass products across various sectors.

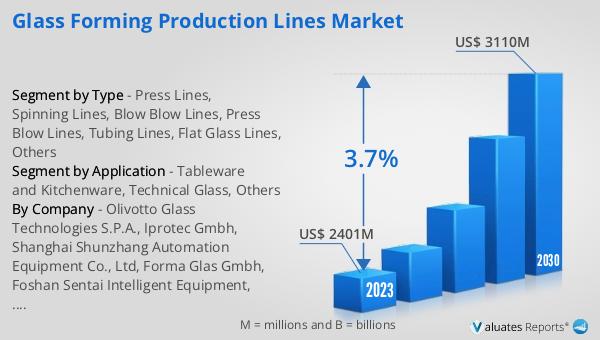

Global Glass Forming Production Lines Market Outlook:

The outlook for the Global Glass Forming Production Lines Market indicates a promising growth trajectory. The market is anticipated to expand from a valuation of $2,499 million in 2024 to $3,214 million by 2031, reflecting a compound annual growth rate (CAGR) of 3.7% from 2025 to 2031. This growth is primarily driven by the increasing demand for glass products across various industries and the continuous advancements in production line technology. The market's expansion is supported by the critical product segments that cater to diverse end-use applications, ensuring that manufacturers can meet the evolving needs of their customers. As industries such as construction, automotive, and consumer goods continue to rely on glass products for their operations, the demand for efficient and high-quality production lines is expected to rise. Additionally, the focus on sustainability and energy efficiency in manufacturing processes is driving innovation in the market, leading to the development of advanced production lines that minimize environmental impact. As a result, manufacturers are investing in new technologies and upgrading their existing production lines to enhance their capabilities and remain competitive in the market. The Global Glass Forming Production Lines Market is poised for significant growth, driven by the increasing demand for glass products and the continuous advancements in production line technology.

| Report Metric | Details |

| Report Name | Glass Forming Production Lines Market |

| Accounted market size in 2024 | US$ 2499 million |

| Forecasted market size in 2031 | US$ 3214 million |

| CAGR | 3.7% |

| Base Year | 2024 |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Sales by Region |

|

| By Company | Olivotto Glass Technologies S.P.A., Iprotec Gmbh, Shanghai Shunzhang Automation Equipment Co., Ltd, Forma Glas Gmbh, Foshan Sentai Intelligent Equipment, Nanjing Guanping Machinery Co., Ltd, Shanghai Aijitim Glass Machinery Technology Co., Ltd, Bucher Emhart Glass, Bdf Industries S.P.A., Heye International, CMS Glass Machinery, Stevanato Group, BOTTERO SpA, Toyo Glass Machinery Co., Ltd, Takeuchi Manufacturing Co., Ltd, Sklostroj Turnov |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |