What is Global CNC Controls Market?

The Global CNC Controls Market refers to the worldwide industry focused on the production, distribution, and utilization of Computer Numerical Control (CNC) systems. These systems are pivotal in automating the control of machining tools and 3D printers through computers, enhancing precision, efficiency, and productivity in manufacturing processes. CNC controls are integral to various industries, including automotive, aerospace, and electronics, as they enable the precise shaping and forming of materials like metal, plastic, and wood. The market encompasses a wide range of products, from basic to high-end CNC controllers, each catering to different levels of complexity and application requirements. As industries increasingly adopt automation to improve production capabilities and reduce human error, the demand for advanced CNC controls continues to grow. This market is characterized by rapid technological advancements, with manufacturers constantly innovating to offer more sophisticated and user-friendly solutions. The global CNC controls market is also influenced by factors such as the rise in industrialization, the need for mass production, and the growing emphasis on reducing operational costs. As a result, this market plays a crucial role in shaping the future of manufacturing across the globe.

Basic CNC controller, Intermediate CNC controller, High-end CNC controller in the Global CNC Controls Market:

In the realm of CNC controls, there are three primary categories: Basic CNC controllers, Intermediate CNC controllers, and High-end CNC controllers, each serving distinct purposes and industries. Basic CNC controllers are typically used in simpler applications where the complexity of tasks is minimal. These controllers are designed for straightforward operations, often found in small workshops or educational settings where the primary focus is on learning and basic production tasks. They offer essential functionalities such as basic motion control and limited programming capabilities, making them ideal for entry-level users or small-scale operations that do not require advanced features. Despite their simplicity, basic CNC controllers are crucial for introducing automation to smaller businesses, enabling them to improve efficiency and accuracy without significant investment. Intermediate CNC controllers, on the other hand, cater to more complex applications and are often used in medium-sized manufacturing operations. These controllers offer enhanced functionalities compared to basic models, including more sophisticated programming options, better motion control, and the ability to handle more complex tasks. They are suitable for industries that require a higher degree of precision and efficiency, such as automotive parts manufacturing or mid-sized electronics production. Intermediate CNC controllers strike a balance between cost and capability, providing businesses with the tools needed to increase productivity and maintain competitive advantage without the high costs associated with high-end systems. They often include features like multi-axis control, advanced user interfaces, and improved connectivity options, allowing for more seamless integration into existing manufacturing processes. High-end CNC controllers represent the pinnacle of CNC technology, offering the most advanced features and capabilities. These controllers are used in industries where precision, speed, and reliability are paramount, such as aerospace, defense, and high-end automotive manufacturing. High-end CNC controllers are equipped with state-of-the-art technology, including real-time monitoring, adaptive control systems, and the ability to handle extremely complex machining tasks. They support a wide range of functions, from multi-axis machining to intricate 3D modeling, and are designed to operate in demanding environments where downtime and errors can be costly. The investment in high-end CNC controllers is justified by the significant improvements in production quality and efficiency they provide, making them indispensable for companies aiming to lead in innovation and quality. These controllers often feature advanced software integration, allowing for seamless communication with other systems and enabling manufacturers to implement smart factory solutions. As industries continue to push the boundaries of what is possible with CNC technology, high-end controllers will play a critical role in driving innovation and maintaining competitive advantage.

机械制造, 汽车工业, 航天国防, 其他 in the Global CNC Controls Market:

The Global CNC Controls Market finds extensive application across various industries, including 机械制造 (machinery manufacturing), 汽车工业 (automotive industry), 航天国防 (aerospace and defense), and 其他 (others). In the realm of machinery manufacturing, CNC controls are indispensable for producing complex components with high precision and efficiency. These systems enable manufacturers to automate repetitive tasks, reduce human error, and increase production speed, which is crucial in meeting the demands of modern manufacturing. CNC controls allow for the production of intricate parts that would be difficult or impossible to achieve manually, thus enhancing the capabilities of machinery manufacturers to innovate and improve their product offerings. In the automotive industry, CNC controls are vital for producing a wide range of components, from engine parts to body panels. The precision and repeatability offered by CNC systems ensure that each part meets strict quality standards, which is essential in an industry where safety and reliability are paramount. CNC controls also enable automotive manufacturers to implement flexible manufacturing processes, allowing them to quickly adapt to changing market demands and produce customized products efficiently. This flexibility is particularly important as the automotive industry shifts towards electric vehicles and other emerging technologies, requiring new components and manufacturing techniques. The aerospace and defense sectors rely heavily on CNC controls for the production of high-precision components used in aircraft, spacecraft, and military equipment. The stringent quality and safety standards in these industries necessitate the use of advanced CNC systems capable of producing parts with exceptional accuracy and consistency. CNC controls enable aerospace and defense manufacturers to produce complex geometries and lightweight structures that are critical for performance and efficiency. Additionally, the ability to automate production processes reduces lead times and costs, allowing companies to remain competitive in a highly demanding market. Beyond these primary industries, CNC controls are also used in a variety of other sectors, including electronics, medical devices, and consumer goods. In electronics manufacturing, CNC systems are used to produce circuit boards and other components with high precision, ensuring the reliability and performance of electronic devices. In the medical field, CNC controls enable the production of intricate surgical instruments and implants, where precision and quality are critical. The versatility of CNC technology allows it to be adapted to a wide range of applications, making it an essential tool for manufacturers across diverse industries. As the demand for high-quality, customized products continues to grow, the role of CNC controls in driving innovation and efficiency in manufacturing will only become more significant.

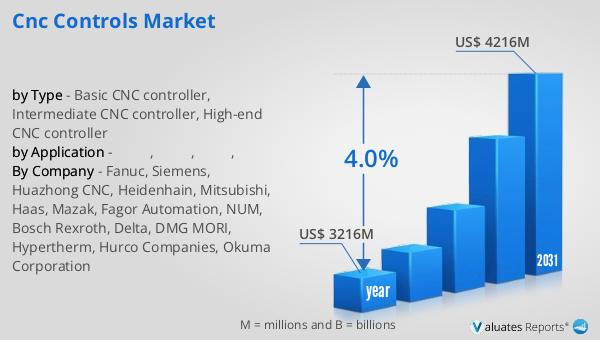

Global CNC Controls Market Outlook:

The outlook for the Global CNC Controls Market indicates a promising trajectory of growth. In 2024, the market was valued at approximately US$ 3,216 million, reflecting its significant role in the manufacturing sector. Looking ahead, projections suggest that by 2031, the market will expand to a revised size of US$ 4,216 million. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.0% over the forecast period. This steady increase underscores the rising demand for CNC controls as industries continue to embrace automation and advanced manufacturing technologies. The growth of the CNC controls market is driven by several factors, including the need for increased production efficiency, the demand for high-precision manufacturing, and the ongoing trend towards digitalization in industrial processes. As companies strive to enhance their competitive edge, the adoption of CNC controls is likely to accelerate, contributing to the market's expansion. The projected growth also highlights the importance of innovation and technological advancements in the CNC controls industry, as manufacturers seek to develop more sophisticated and user-friendly solutions to meet the evolving needs of their customers. Overall, the Global CNC Controls Market is poised for significant growth, driven by the increasing adoption of automation and the continuous pursuit of manufacturing excellence.

| Report Metric | Details |

| Report Name | CNC Controls Market |

| Accounted market size in year | US$ 3216 million |

| Forecasted market size in 2031 | US$ 4216 million |

| CAGR | 4.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Fanuc, Siemens, Huazhong CNC, Heidenhain, Mitsubishi, Haas, Mazak, Fagor Automation, NUM, Bosch Rexroth, Delta, DMG MORI, Hypertherm, Hurco Companies, Okuma Corporation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |