What is Global Steel Forging for Automotive Market?

The Global Steel Forging for Automotive Market is a crucial segment within the automotive industry, focusing on the production of high-strength components through the process of forging. Forging is a manufacturing process where metal is shaped using compressive forces, resulting in parts that are exceptionally strong and durable. In the automotive sector, steel forging is particularly important because it produces components that can withstand high stress and strain, which is essential for vehicle safety and performance. This market encompasses a wide range of automotive parts, including bearings, crankshafts, and pistons, which are integral to the functioning of both passenger cars and commercial vehicles. The demand for steel forging in the automotive industry is driven by the need for lightweight yet strong materials that can improve fuel efficiency and reduce emissions. As automotive technology advances, the market for steel forging continues to grow, adapting to new challenges and innovations in vehicle design and manufacturing. The global steel forging market is characterized by its focus on quality, precision, and the ability to produce complex shapes that meet the stringent requirements of modern automotive engineering.

Bearing, Crankshaft, Piston, Other in the Global Steel Forging for Automotive Market:

In the Global Steel Forging for Automotive Market, several key components are produced, each playing a vital role in vehicle operation and performance. Bearings, for instance, are essential for reducing friction between moving parts, ensuring smooth and efficient operation of the vehicle. They are used in various parts of the car, including the wheels, engine, and transmission, and are crucial for maintaining the vehicle's stability and handling. Forged steel bearings are preferred for their strength and durability, which are necessary to withstand the high loads and stresses encountered during driving. Crankshafts, another critical component, are responsible for converting the linear motion of the pistons into rotational motion, which ultimately powers the vehicle. Forged steel crankshafts are favored for their ability to handle the immense forces generated within the engine, providing reliability and longevity. Pistons, which move up and down within the engine cylinders, are also commonly forged from steel to ensure they can endure the high temperatures and pressures of combustion. The precision and strength of forged steel pistons contribute to the engine's efficiency and performance. Other components produced through steel forging include connecting rods, gears, and axles, each of which plays a crucial role in the vehicle's overall functionality. Connecting rods connect the pistons to the crankshaft, transferring the force generated by the pistons to the crankshaft. Forged steel connecting rods are essential for high-performance engines, where strength and reliability are paramount. Gears, used in the transmission system, are responsible for transferring power from the engine to the wheels, allowing the vehicle to move at different speeds. Forged steel gears are known for their ability to withstand high torque and stress, ensuring smooth and efficient power transfer. Axles, which support the weight of the vehicle and its cargo, are also commonly forged from steel to provide the necessary strength and durability. The use of forged steel in these components is driven by the need for materials that can withstand the demanding conditions of automotive operation, including high temperatures, pressures, and mechanical stresses. As the automotive industry continues to evolve, the demand for high-quality forged steel components is expected to grow, driven by advancements in vehicle technology and the increasing emphasis on safety, performance, and efficiency.

Passenger Car, Commercial Vehicle in the Global Steel Forging for Automotive Market:

The usage of Global Steel Forging for Automotive Market components is prevalent in both passenger cars and commercial vehicles, each with its unique requirements and challenges. In passenger cars, the focus is often on providing a smooth, comfortable, and efficient driving experience. Forged steel components play a crucial role in achieving these goals by ensuring the vehicle's reliability and performance. For instance, forged steel bearings are used in the wheels and suspension systems to reduce friction and improve handling, contributing to a smoother ride. Crankshafts and pistons, forged from steel, are essential for the engine's operation, providing the necessary strength and durability to withstand the high pressures and temperatures of combustion. These components help improve fuel efficiency and reduce emissions, which are critical considerations for modern passenger cars. In commercial vehicles, such as trucks and buses, the demands on forged steel components are even greater due to the heavier loads and more demanding operating conditions. Forged steel axles, for example, are essential for supporting the weight of the vehicle and its cargo, providing the necessary strength and durability to withstand the stresses of heavy-duty operation. Similarly, forged steel gears and connecting rods are crucial for the transmission and engine systems, ensuring reliable power transfer and performance under challenging conditions. The use of forged steel in commercial vehicles is driven by the need for components that can endure the rigors of long-distance travel, heavy loads, and frequent use. As the automotive industry continues to evolve, the demand for high-quality forged steel components in both passenger cars and commercial vehicles is expected to grow. This growth is driven by advancements in vehicle technology, increasing emphasis on safety and performance, and the need for materials that can meet the stringent requirements of modern automotive engineering. The Global Steel Forging for Automotive Market is poised to play a critical role in meeting these demands, providing the strength, durability, and precision necessary for the next generation of vehicles.

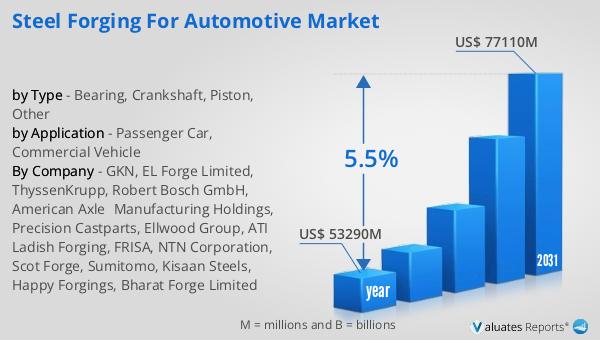

Global Steel Forging for Automotive Market Outlook:

The outlook for the Global Steel Forging for Automotive Market indicates a promising future, with significant growth expected over the coming years. In 2024, the market was valued at approximately US$ 53,290 million, reflecting the substantial demand for forged steel components in the automotive industry. This demand is driven by the need for high-strength, durable materials that can withstand the rigorous conditions of automotive operation. As the industry continues to evolve, with advancements in vehicle technology and increasing emphasis on safety, performance, and efficiency, the market for steel forging is projected to expand significantly. By 2031, the market is expected to reach a revised size of US$ 77,110 million, growing at a compound annual growth rate (CAGR) of 5.5% during the forecast period. This growth is indicative of the critical role that forged steel components play in the automotive industry, providing the strength, durability, and precision necessary for modern vehicles. The increasing demand for lightweight, fuel-efficient vehicles is also contributing to the growth of the steel forging market, as manufacturers seek materials that can help reduce weight without compromising on performance or safety. As a result, the Global Steel Forging for Automotive Market is poised to continue its upward trajectory, driven by the ongoing advancements in automotive technology and the ever-increasing demands of the industry.

| Report Metric | Details |

| Report Name | Steel Forging for Automotive Market |

| Accounted market size in year | US$ 53290 million |

| Forecasted market size in 2031 | US$ 77110 million |

| CAGR | 5.5% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | GKN, EL Forge Limited, ThyssenKrupp, Robert Bosch GmbH, American Axle&Manufacturing Holdings, Precision Castparts, Ellwood Group, ATI Ladish Forging, FRISA, NTN Corporation, Scot Forge, Sumitomo, Kisaan Steels, Happy Forgings, Bharat Forge Limited |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |