What is Global Aluminum Oxide Ceramic Substrates Market?

The Global Aluminum Oxide Ceramic Substrates Market is a specialized segment within the broader ceramics industry, focusing on the production and application of aluminum oxide (Al2O3) ceramic substrates. These substrates are known for their exceptional thermal conductivity, electrical insulation, and mechanical strength, making them ideal for various high-performance applications. Aluminum oxide ceramic substrates are widely used in electronics, automotive, aerospace, and telecommunications industries due to their ability to withstand high temperatures and harsh environments. The market is driven by the increasing demand for miniaturized electronic devices, which require substrates that can efficiently dissipate heat and provide reliable electrical insulation. Additionally, the growing trend towards renewable energy sources and electric vehicles is boosting the demand for these substrates, as they are essential components in power electronics and battery management systems. The market is characterized by continuous innovation and development of advanced materials to meet the evolving needs of end-users. Manufacturers are focusing on enhancing the properties of aluminum oxide ceramic substrates, such as improving their thermal conductivity and reducing their thickness, to cater to the demands of modern electronic devices.

96% Alumina (Al2O3) Substrates, ZTA Substrates, Others in the Global Aluminum Oxide Ceramic Substrates Market:

96% Alumina (Al2O3) Substrates, ZTA Substrates, and other types of substrates play a crucial role in the Global Aluminum Oxide Ceramic Substrates Market. 96% Alumina substrates are the most commonly used type due to their excellent balance of cost and performance. They offer good thermal conductivity, electrical insulation, and mechanical strength, making them suitable for a wide range of applications, including electronic circuits, LED lighting, and power modules. These substrates are often used in applications where high thermal and electrical performance is required, but cost is also a consideration. On the other hand, Zirconia Toughened Alumina (ZTA) substrates are a more advanced type of ceramic substrate that combines the properties of alumina and zirconia. ZTA substrates offer enhanced mechanical strength and fracture toughness compared to standard alumina substrates, making them ideal for applications that require high durability and resistance to mechanical stress. They are often used in high-performance applications such as aerospace and defense, where reliability and longevity are critical. Other types of substrates in the market include high-purity alumina substrates, which offer superior thermal and electrical properties but at a higher cost. These substrates are used in specialized applications where performance is the primary concern, such as in high-frequency communication devices and advanced semiconductor packaging. The choice of substrate type depends on the specific requirements of the application, including thermal and electrical performance, mechanical strength, and cost considerations. Manufacturers in the market are continuously innovating to develop new substrate materials that offer improved performance and cost-effectiveness. This includes the development of composite substrates that combine different ceramic materials to achieve a balance of properties that meet the needs of modern electronic devices. The market is also seeing a trend towards the miniaturization of substrates, driven by the demand for smaller and more efficient electronic devices. This requires the development of substrates with thinner profiles and higher thermal and electrical performance. Overall, the Global Aluminum Oxide Ceramic Substrates Market is characterized by a diverse range of substrate types, each with its own unique properties and applications. The market is driven by the need for high-performance materials that can meet the demands of modern technology, and manufacturers are continuously innovating to develop new and improved substrate materials.

DBC Ceramic Substrates, DPC Ceramic Substrates, Thick Film & Thin Film Substrates, Chip Resistor Ceramic Substrates, Others in the Global Aluminum Oxide Ceramic Substrates Market:

The Global Aluminum Oxide Ceramic Substrates Market finds extensive usage in various applications, including DBC Ceramic Substrates, DPC Ceramic Substrates, Thick Film & Thin Film Substrates, Chip Resistor Ceramic Substrates, and others. DBC (Direct Bonded Copper) Ceramic Substrates are widely used in power electronics due to their excellent thermal conductivity and electrical insulation properties. They are commonly used in applications such as power modules, inverters, and motor drives, where efficient heat dissipation is critical. DPC (Direct Plated Copper) Ceramic Substrates, on the other hand, offer superior electrical performance and are used in high-frequency applications such as RF modules and microwave circuits. They provide excellent thermal management and electrical conductivity, making them ideal for advanced communication devices. Thick Film & Thin Film Substrates are used in a variety of electronic applications, including hybrid circuits, sensors, and resistors. Thick film substrates are known for their durability and ability to withstand harsh environments, making them suitable for automotive and industrial applications. Thin film substrates, on the other hand, offer high precision and are used in applications where miniaturization and high performance are required, such as in medical devices and advanced sensors. Chip Resistor Ceramic Substrates are used in the production of chip resistors, which are essential components in electronic circuits. These substrates provide excellent thermal and electrical performance, ensuring the reliability and longevity of the resistors. Other applications of aluminum oxide ceramic substrates include LED lighting, where they are used to provide efficient heat dissipation and electrical insulation, and semiconductor packaging, where they offer high thermal conductivity and mechanical strength. The versatility and high performance of aluminum oxide ceramic substrates make them an essential component in a wide range of applications, driving their demand in the global market. Manufacturers are continuously developing new substrate materials and technologies to meet the evolving needs of these applications, ensuring the continued growth and innovation in the market.

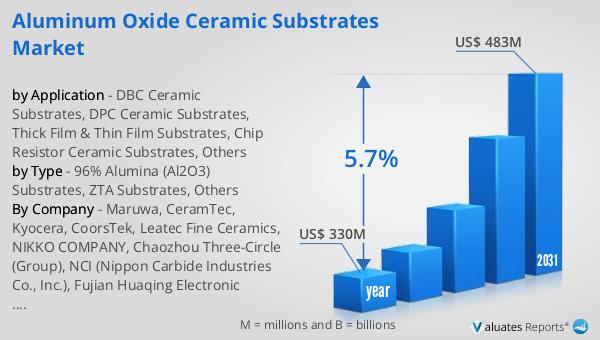

Global Aluminum Oxide Ceramic Substrates Market Outlook:

The global market for Aluminum Oxide Ceramic Substrates was valued at $330 million in 2024 and is anticipated to grow to a revised size of $483 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.7% during the forecast period. This growth is driven by the increasing demand for high-performance electronic devices and the need for efficient thermal management solutions. As industries such as electronics, automotive, and telecommunications continue to evolve, the demand for advanced materials like aluminum oxide ceramic substrates is expected to rise. These substrates offer a unique combination of thermal conductivity, electrical insulation, and mechanical strength, making them ideal for a wide range of applications. The market is also benefiting from the growing trend towards miniaturization and the development of new technologies that require high-performance materials. Manufacturers are investing in research and development to create innovative substrate materials that meet the demands of modern technology. The market is characterized by continuous innovation and the development of new materials and technologies that enhance the performance and cost-effectiveness of aluminum oxide ceramic substrates. As the market continues to grow, manufacturers are focusing on developing new substrate materials that offer improved performance and cost-effectiveness, ensuring the continued growth and innovation in the market.

| Report Metric | Details |

| Report Name | Aluminum Oxide Ceramic Substrates Market |

| Accounted market size in year | US$ 330 million |

| Forecasted market size in 2031 | US$ 483 million |

| CAGR | 5.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Maruwa, CeramTec, Kyocera, CoorsTek, Leatec Fine Ceramics, NIKKO COMPANY, Chaozhou Three-Circle (Group), NCI (Nippon Carbide Industries Co., Inc.), Fujian Huaqing Electronic Material Technology, Sinoceram Technology (zhengzhou) Co., Ltd, Zhejiang Xinna Ceramic New Material |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |