What is Global Polyester Dipped Cord Market?

The Global Polyester Dipped Cord Market is a specialized segment within the broader textile and materials industry, focusing on the production and application of polyester cords that have been treated with a dipping process. This process involves coating the polyester cords with a specific chemical solution to enhance their properties, such as strength, durability, and resistance to environmental factors. These cords are primarily used in reinforcing materials where high tensile strength and durability are required, such as in tires, conveyor belts, and hoses. The market is driven by the increasing demand for durable and high-performance materials in various industrial applications. As industries continue to seek materials that offer both strength and flexibility, polyester dipped cords have become an essential component in manufacturing processes. The market's growth is also supported by advancements in dipping technologies, which have improved the quality and performance of these cords. Additionally, the global push towards more sustainable and efficient materials has further fueled the demand for polyester dipped cords, as they offer a balance between performance and environmental considerations. Overall, the Global Polyester Dipped Cord Market is poised for steady growth as industries continue to innovate and expand their use of these versatile materials.

High Modulus Low Shrinkage, High Strength Type in the Global Polyester Dipped Cord Market:

High Modulus Low Shrinkage (HMLS) and High Strength types of polyester dipped cords are critical components in the Global Polyester Dipped Cord Market, each offering unique properties that cater to specific industrial needs. HMLS polyester cords are designed to provide exceptional dimensional stability and minimal shrinkage under high temperatures, making them ideal for applications where maintaining shape and size is crucial. This type of cord is particularly beneficial in the tire industry, where it helps maintain the structural integrity of tires under varying conditions. The low shrinkage property ensures that the cords do not contract significantly when exposed to heat, thus preserving the tire's performance and safety. On the other hand, High Strength polyester cords are engineered to offer superior tensile strength, making them suitable for applications that require robust reinforcement. These cords are often used in heavy-duty conveyor belts and hoses, where they provide the necessary strength to withstand high loads and pressures. The combination of high strength and flexibility allows these cords to perform effectively in demanding environments, ensuring the longevity and reliability of the products they reinforce. The development of these specialized cords is driven by the need for materials that can meet the rigorous demands of modern industrial applications. As industries continue to evolve, the demand for HMLS and High Strength polyester dipped cords is expected to grow, driven by their ability to enhance product performance and durability. The production of these cords involves advanced manufacturing processes that ensure consistent quality and performance. Manufacturers invest in research and development to improve the properties of these cords, focusing on enhancing their strength, flexibility, and resistance to environmental factors. This continuous innovation is crucial in maintaining the competitiveness of polyester dipped cords in the global market. Furthermore, the environmental impact of polyester dipped cords is an important consideration for manufacturers and consumers alike. The industry is increasingly focused on developing sustainable production methods and materials that reduce the environmental footprint of these cords. This includes the use of recycled materials and the implementation of energy-efficient manufacturing processes. As a result, polyester dipped cords are becoming more environmentally friendly, aligning with the global trend towards sustainability. In conclusion, High Modulus Low Shrinkage and High Strength polyester dipped cords play a vital role in the Global Polyester Dipped Cord Market, offering essential properties that meet the demands of various industrial applications. Their continued development and innovation are key to supporting the growth of industries that rely on high-performance materials. As the market evolves, these cords will remain integral to the production of durable and reliable products, ensuring their relevance in the years to come.

Conveyor Belts, Hose, Tire, Others in the Global Polyester Dipped Cord Market:

The Global Polyester Dipped Cord Market finds extensive usage in several key areas, including conveyor belts, hoses, tires, and other industrial applications. In the realm of conveyor belts, polyester dipped cords are essential for providing the necessary strength and flexibility to handle heavy loads and continuous operation. These cords reinforce the belts, ensuring they can withstand the rigors of industrial environments, such as mining, manufacturing, and logistics. The durability and resilience of polyester dipped cords make them ideal for conveyor belts that require long-lasting performance and minimal maintenance. In the hose industry, polyester dipped cords are used to reinforce hoses that transport fluids and gases under high pressure. The high tensile strength of these cords ensures that the hoses can withstand the pressure without bursting or leaking, making them suitable for applications in the automotive, construction, and agricultural sectors. The flexibility of polyester dipped cords also allows hoses to bend and flex without compromising their structural integrity, ensuring reliable performance in demanding conditions. In the tire industry, polyester dipped cords are used as reinforcement materials to enhance the strength and durability of tires. These cords help maintain the shape and performance of tires under various conditions, such as high speeds and heavy loads. The use of polyester dipped cords in tires contributes to improved safety and longevity, making them a preferred choice for manufacturers seeking to produce high-quality, reliable tires. Beyond these primary applications, polyester dipped cords are also used in other industrial products that require strong and durable reinforcement. This includes products such as industrial fabrics, geotextiles, and composite materials, where the properties of polyester dipped cords enhance the overall performance and lifespan of the products. The versatility of polyester dipped cords makes them a valuable component in a wide range of industrial applications, supporting the growth and development of various sectors. As industries continue to demand materials that offer both strength and flexibility, the usage of polyester dipped cords is expected to expand, driven by their ability to meet the rigorous demands of modern industrial applications. The ongoing innovation and development in the production of polyester dipped cords will further enhance their performance and sustainability, ensuring their continued relevance in the global market.

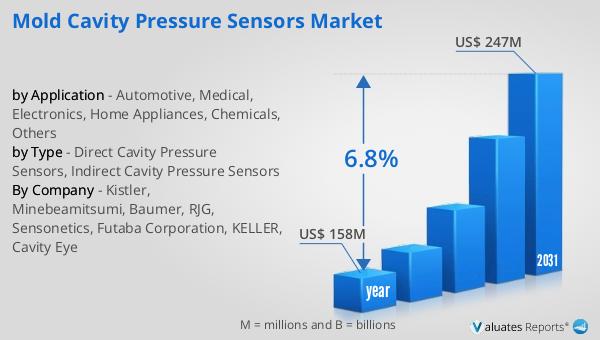

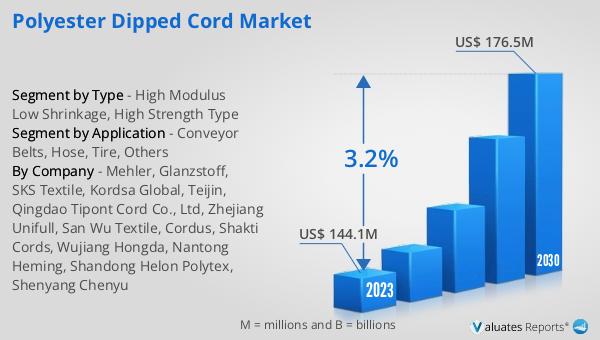

Global Polyester Dipped Cord Market Outlook:

The global market for polyester dipped cords was valued at approximately $150 million in 2024, with projections indicating that it will grow to a revised size of $187 million by 2031. This growth represents a compound annual growth rate (CAGR) of 3.2% over the forecast period. The steady increase in market size reflects the rising demand for high-performance materials across various industries, including automotive, construction, and manufacturing. As industries continue to seek materials that offer both strength and flexibility, polyester dipped cords have become an essential component in manufacturing processes. The market's growth is also supported by advancements in dipping technologies, which have improved the quality and performance of these cords. Additionally, the global push towards more sustainable and efficient materials has further fueled the demand for polyester dipped cords, as they offer a balance between performance and environmental considerations. The market's expansion is indicative of the increasing importance of polyester dipped cords in industrial applications, where their unique properties provide significant advantages over traditional materials. As the market continues to evolve, manufacturers are likely to invest in research and development to further enhance the properties of polyester dipped cords, ensuring their continued relevance and competitiveness in the global market.

| Report Metric | Details |

| Report Name | Polyester Dipped Cord Market |

| Accounted market size in year | US$ 150 million |

| Forecasted market size in 2031 | US$ 187 million |

| CAGR | 3.2% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Mehler, Glanzstoff, SKS Textile, Kordsa Global, Teijin, Qingdao Tipont Cord Co., Ltd, Zhejiang Unifull, San Wu Textile, Cordus, Shakti Cords, Wujiang Hongda, Nantong Heming, Shandong Helon Polytex, Shenyang Chenyu |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |